Progress in bioink development is helping to boost the performance of 3D printed scaffolds, which in turn could benefit the repair of damaged organs and tissues. Bioinks are particularly useful because they enable scaffold designs to be seeded with cells as part of the manufacturing process. They also help in matching the scaffold to the surrounding tissue by enabling different cell types to be distributed at different locations in the bioprinted constructs.

But what’s the optimum combination of bioink properties for a given application, and how can developers use this knowledge to further improve their designs?

“The focus was initially on areas such as bioink viscosity, gelation mechanisms, precision construction, and biocompatibility in the context of a particular bioprinting approach,” comments Aleksandr Ovsianikov, who is based at Vienna University of Technology and a member of the Austrian cluster for tissue regeneration. “However, for most bioprinting technologies bioink development is long past the point when it was simply about process compatibility and cell survival; novel formulations are expected to also offer an instructive environment for the cells.”

His team, which includes colleagues in the US, Belgium and China, has reviewed the properties of bioinks before, during and after 3D bioprinting, with the aim of determining the various process parameters that affect cell-containing scaffolds assembled layer-by-layer. The topical review, published in the journal Biofabrication, also identifies modelling tools that could help designers to explore new materials combinations for tissue repair and adapt them to an expanding range of bioprinting scenarios.

Computational approaches can assist in the synthesis of novel materials, but they can also help to predict the properties during maturation of bioprinted constructs.

Aleksandr Ovsianikov, Vienna University of Technology

Bioink development is made difficult by the changing demands that are placed on formulations. Scaffold manufacturing is just one consideration, and developers need to adapt the ink to suit all stages of the application.

“Different bioprinting technologies and even using a different nozzle diameter for the same approach will result in varying requirements in terms of bioink properties,” comments Ovsianikov. “In addition, the properties of a hydrogel with regard to the bioprinting process and subsequent cell culturing are often opposing.”

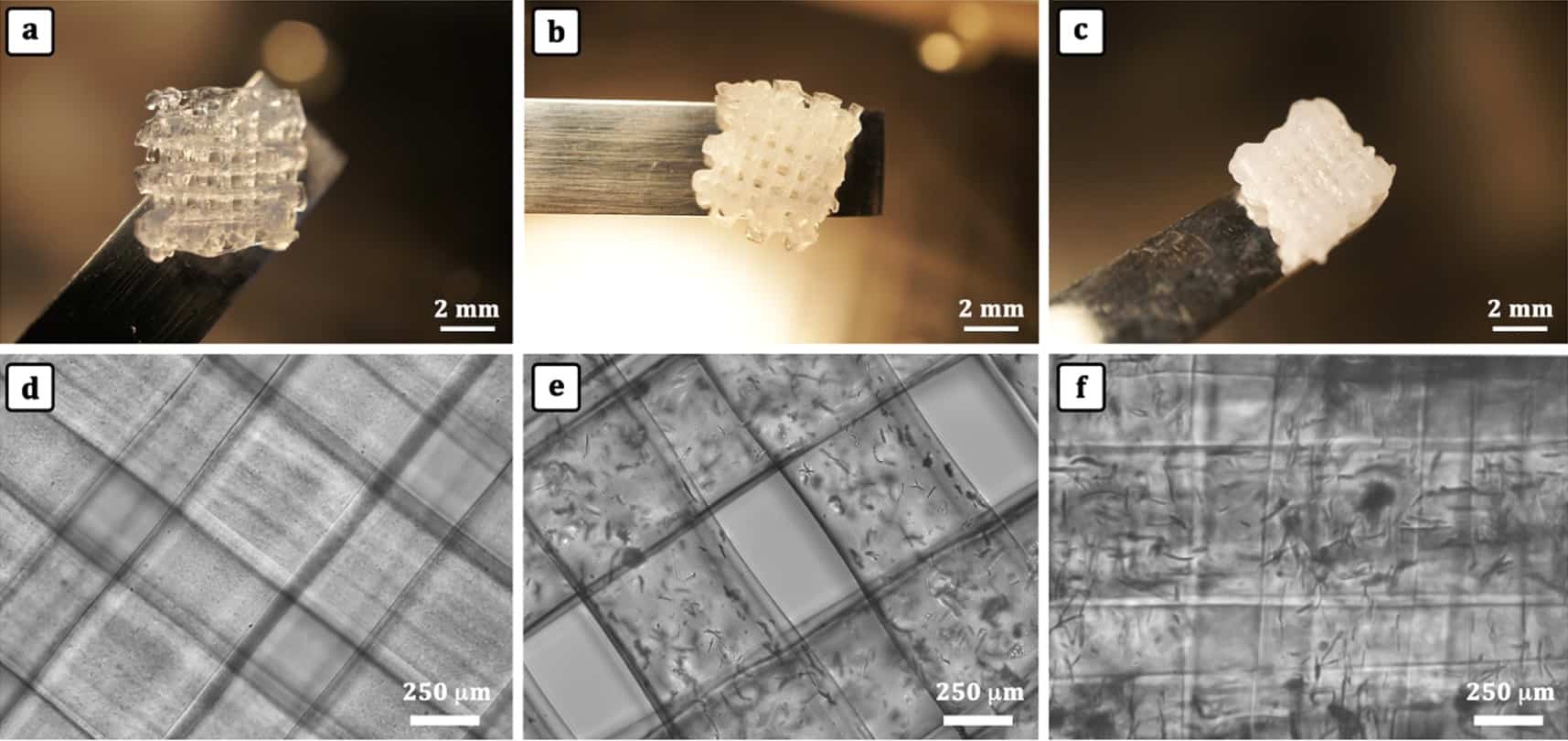

Hydrogels that deliver a stiffer structure help to preserve the integrity of a scaffold design during treatment, but softer versions typically provide a more familiar environment for cells. The scenario presents scaffold designers with a challenge when optimizing inks for tissue growth. To overcome the hurdle, researchers are exploring the use of hybrid systems that combine a range of material properties in their structures.

“A hybrid approach offers much greater flexibility for independently adjusting the rigidity of the overall construct and the mechanical properties of cell-containing bionks,” Ovsianikov explains.

Considering the fine-tuning of formulations for greater success, he sees opportunities for computational methods to contribute to the process on a number of levels.

“On the one hand, computational approaches can assist in the synthesis of novel materials, but they can also help to predict the properties during maturation of bioprinted constructs,” Ovsianikov points out.

Elastomeric bioink makes 3D printing more flexible

Tissue development is governed by multiple factors such as cell proliferation, material degradation and matrix remodelling. Computational insight into this dynamic behaviour will aid designers in optimizing printed constructs towards the expected target properties of the tissue in question.

The topical review highlights numerical work examining the impact of cell density on desirable mechanical properties. Predictions of the mechanical response of cells in various printed hydrogel architectures could be integrated with experimental loadings to determine promising scaffold combinations. The method could also be used to evaluate fabrication conditions, offering a perspective on parameters such as printing speed or nozzle diameter for optimum bioink deposition.

More details can be found in the journal Biofabrication.

- This article is one of a series of reports reviewing progress on high-impact research originally published in the IOP Publishing journal Biofabrication.