What do the heart and the vocal cords have in common? They are constantly vibrating, albeit at different frequencies. While biological tissue is tough enough to withstand these vibrations, designing synthetic tissue that can survive such a dynamic environment remains a major challenge in regenerative medicine.

Scientists from McGill University have developed a new type of injectable hydrogel that is resistant to prolonged, high-frequency stimulation. Describing their findings in Advanced Science, the researchers believe that the hydrogel’s unique combination of properties, including mechanical integrity, high porosity and cell compatibility, could one day enable the repair of muscular tissues such as the heart and vocal cords.

“Our work highlights the synergy of materials science, mechanical engineering and bioengineering in creating novel biomaterials with unprecedented performance,” says Jianyu Li, who led the team alongside colleague Luc Mongeau.

“We hope that one day the new hydrogel will be used as an implant to restore the voice of people with damaged vocal cords, for example laryngeal cancer survivors,” adds co-first author Guangyu Bao.

Putting the hydrogel through its paces

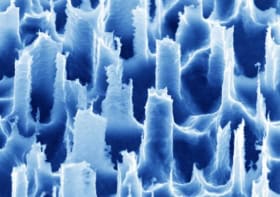

Our vocal cords vibrate to produce sounds at a frequency of 100 to 300 Hz. Many hydrogels break down under these conditions due to their porous structure. Pores are an essential feature of implantable biomaterials because they allow oxygen and nutrients to perfuse through the implant, which is crucial for cell survival. Unfortunately, porosity often comes at the expense of mechanical strength, especially under dynamic loads.

To combat this, the researchers developed a specific type of hydrogel called a porous double-network (PDN) hydrogel. The two polymer networks used to form the PDN, chitosan (a sugar found in the outer skeleton of shellfish) and glycol–chitosan, are difficult to separate from one another. This results in a stretchy material that resists fracture. In fact, PDNs can resist millions of cycles of mechanical loading compared to their porous single-network (PSN) counterparts.

“Most synthetic materials developed so far for vocal cord repair are based on single-network hydrogels,” Bao tells Physics World. “Currently, patients may need periodic injections because those hydrogels do not last long. Our hydrogel offers a five to 40-fold increase in toughness, which could potentially improve the retention of the hydrogel after injection.”

Using a perfusable vocal cord bioreactor, the team subjected the PDN and a chitosan-based PSN to over six million cycles of 120 Hz vibrations – that’s the equivalent of talking for two hours every day for a week. Not only did the PDN remain intact after loading, but cells encapsulated within the hydrogel were viable throughout the seven-day period. On the other hand, the PSN fractured into pieces.

Accelerated wound repair

What sets the PDN apart from other injectable double-network hydrogels is its ability to form cell-sized pores upon injection. Injectable hydrogels are desirable in many areas of regenerative medicine, from drug delivery to lab-on-a-chip disease models. Most injectable hydrogels form nanosized pores, meaning that they suffer from low permeability. The team found that cells could not proliferate inside a nanoporous glycol–chitosan hydrogel, but could inside the PDN.

“We utilize the phase separation behaviour of chitosan to create pores on the microscale,” explains Bao. “This feature can facilitate cell recruitment from native tissues to help accelerate wound repair.”

By varying the concentration of glycol–chitosan, the researchers could further control key parameters like stiffness and porosity. They also found that their fabrication technique was compatible with other types of polymers, such as gelatin.

Future steps

The team believes that this study could form the basis of a new class of tough, injectable hydrogels. After investigating the biocompatibility, biodegradability and theurapeutic performance of the PDN in animal models, the researchers hope to apply for permission to perform clinical trials.

While their study focused on frequencies relating to vocal cords, they emphasize that the hydrogel is tough enough to repair other soft tissues under dynamic loading.

“People recovering from heart damage often face a long and tricky journey. Healing is challenging because of the constant movement tissues must withstand as the heart beats,” says Bao. “We are curious to know [the hydrogel’s] efficacy in cardiac tissue engineering and welcome collaboration with scientists in those fields.”