From synchrotron light sources to long-term space missions, nanopositioning specialist Queensgate is eyeing niche markets and extreme operating conditions for its NC series of nanosensors

The new NanoCeramic (NC) NanoSensor series from Queensgate, a specialist UK manufacturer of high-precision nanopositioning products, offers nanoscale metrology that’s tailor-made for the most demanding of research environments – combining ultrahigh-vacuum (UHV) compatibility and radiation-hardness with operation at cryogenic through to elevated temperatures.

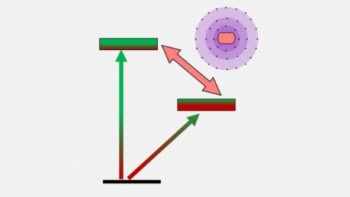

For context, Queensgate’s NanoSensor product portfolio comprises an established family of non-contact position measuring systems (the NX series) based on the principle of capacitance micrometry. Two sensor plates – a target and a probe – form a parallel-plate capacitor, with the spacing of the plates measured using an electronic controller.

Measurement ranges from 20 µm to 1250 µm are available with frequency responses up to 20 kHz (ideal for vibration monitoring and detection of noise in precision instrumentation). What’s more, NX series NanoSensors ensure linearity down to 0.02% and measurement resolution as low as 7 pm (RMS) – all in a non-self-heating assembly and with selected designs suitable for UHV operation down to 10-9 Torr.

Made to measure

Based on the same fundamental principles, the NC series represents an extension of the NX offering for deployment under extreme conditions – in effect, a custom line of NanoSensors that takes UHV compatibility to the next level (10-10 Torr) while providing stable, reliable operation in aggressive radiation environments (with radiation-hardened 107 Gy cabling) and across a broad temperature range (from 80 K to 423 K).

“We’re using military- and aerospace-qualified manufacturing techniques to produce the NC series,” explains John Clarke, principal mechanical design engineer at Queensgate. “Although the sensors, for the most part, are custom designs, the manufacturability of NC technology is such that we can deliver along multiple – and very exacting – performance coordinates at a competitive price-point.”

At the heart of the NC measurement subsystem are gold-plated, ceramic capacitive sensor plates (typically based on “white gold”, a platinum—gold alloy), while most models also include a glass ceramic glaze to protect the sensor faces and prevent accidental shorting between the plates. Equally important are the NC’s application-specific sensor housings – not least when it comes to ensuring a low-thermal-expansion design. Invar housings, for example, provide thermal stability at cryogenic temperatures (down to 80 K); stainless steel SS316 is ideal when matching the sensor’s expansion to a stainless-steel structure; and non-magnetic aluminium housings are best used when matching thermal expansion to aluminium structures.

“Fundamentally,” notes Clarke, “the NC series comprises a package of materials advances and innovations to ensure compatibility across a diversity of extreme-environment applications.” A case in point: one of the first NC NanoSensor deployments – to monitor silicon-crystal bending in a Bragg monochromator on a synchrotron beamline – combined a measurement resolution of 2–5 nm with a 100 µm range and operation at cryogenic temperatures (approximately 80 K).

The low-outgassing construction also enabled deployment under UHV conditions (down to 10-9 Torr), while the “radiation-hard” cabling and ceramic/metal construction ensured the sensor could withstand a maximum equivalent radiation dose within the beamline of 143 Gy/hr. “This early NC solution ticked all the boxes in terms of pushing the performance envelope,” adds Clarke.

It’s all about control

A defining feature of the NC sensor series (and the parent NX product line) is high-quality digital control electronics – combining low noise, 20-bit digital output and a 50 kHz update rate as part of an integrated measurement system. There’s also a longer cable-drive capability (versus previous-generation analogue models) to ensure the digital output is less sensitive to noise pick-up.

“All of which means it’s a lot easier for end-users to integrate NC sensors into their control system without introducing noise on the signal,” explains Clarke. “Converting to digital straight away means the end-user can pass the sensor signal down a digital cable to a PC, where it can be analysed and fed into a control loop.”

Other specifications of the NC series include high-linearity output before calibration (0.05% typical), with fourth-order digitally corrected calibration linear to 0.005% (typical). There’s also plug-and-play exchange or repair of the control electronics when the sensor heads are inaccessible – for example, within a vacuum chamber.

The NC series is an expanding product line. If the model required is not available, Queensgate will manufacture to custom specification subject to minimum order quantity criteria.