Researchers in the US have made a “carpet cloak” that makes objects invisible to sound waves. The device is the first such cloak to work in air and could be used to improve the acoustics in concert halls or even to control unwanted noise.

The first light-based invisibility cloak was built in 2006 and the first for sound followed in 2010. Such cloaks are made from special man-made materials that are engineered to have optical or acoustic properties that vary throughout the device. As a result, incoming light or sound waves bend around the cloak and rejoin at the far side as if the cloak – and anything inside it – was never there.

In practice, however, it is extremely difficult to create materials with all the right properties and all cloaks built so far are extremely limited in how they work. The first sound cloak, for example, works in water not air and only works if the sound is propagating in 2D. Another important limitation of many cloaks is that they only work within a narrow band of frequencies.

Under the carpet

Carpet cloaks are a special type of invisibility cloak that offer a way of getting round some of these problems. These cloaks are placed over an object sitting on a reflective surface and render the object invisible. The first optical carpet cloak was made in 2009 and now Steven Cummer and colleagues at Duke University in the US have made a carpet cloak for sound. And, unlike previous acoustic cloaks, it works in air rather than water.

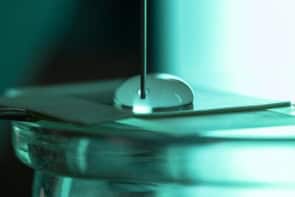

This latest device is made from a set of square plastic plates, each with a hole at its centre. The size of hole has a strong effect on how a sound wave behaves when it is fired straight at the plate. As it passes through the plate, the wave acts if it has entered a region where the mass density of the air has suddenly increased. However, if the wave arrives at a glancing angle to the plate, the hole has little effect and the wave behaves as if it is propagating through air.

The team chose plates that are 5 mm across, 1 mm thick and with a 1.6 mm diameter hole. Layers of the plates were assembled into a 3D chevron-shaped structure (see figure) that was placed upon a hard “ground plane” that reflects sound. The object to be cloaked was placed under the device and sound from a speaker was directed at it. A microphone was then moved throughout the room to map out the sound intensity as a function of position to see how sound scatters from the cloak.

Nearly identical patterns

The team found that the intensity pattern obtained when the cloak and object are present is nearly identical to the pattern obtained from the empty ground plate. The pattern, however, is very different when just the object is present. According to the team, the difference between the patterns from the cloaked object and empty surface are a result of some of the sound being absorbed by the cloak – a problem that most cloak designs suffer from.

The team’s measurements show that the cloak works well over a bandwidth of 1–5 kHz. “Theoretically it should work well below 1 kHz as well, but because the wavelengths are so long it is hard to measure those lower frequencies in our set-up,” explained Cummer. This 0–5 kHz frequency range is about the same as a human voice.

To operate at frequencies above about 6 kHz the size of the plastic plates would have to be reduced. “We can definitely cover the whole range of human hearing (say to 0–15 kHz) without too much trouble,” he said.

This operating range impresses Nicholas Fang of the Massachusetts Institute of Technology who said “The technology is very promising as it is broadband. For example, it might improve sound reflections in auditorium or theatre rooms.”

Designing acoustic surfaces

Cummer agrees, pointing out that the design could be used to give a room an acoustic layout that is different from its actual physical layout. Walls that are smooth to the eye could be made to appear rough to sound and vice versa. This could aid architects and acoustic engineers when designing concert halls, for example.

José Sánchez-Dehesa of Universidad Politécnica de Valencia in Spain believes that further applications could be possible if the concept of the carpet cloak could be extended to vibrations in solid materials. This could be used, for example, to cloak sensitive instruments from vibrations says Sánchez-Dehesa. Looking even further into the future he says that the concept could even be used to protect buildings from earthquakes.

Cummer’s team is now working on a 3D pyramid-shaped cloak and is also trying to develop a similar cloak that works in water rather than air.

The research is described in Phys. Rev. Lett. 106 253901.