Material scientists in the US have invented a simple way to make tough ceramics by using freezing “templates” of ice. The technique, developed by Antoni Tomsia and colleagues at the Lawrence Berkeley National Laboratory, mimics the way seawater freezes and produces layered structures that resemble seashells. The composites, which are less brittle than existing ceramics, could be used to make everything from dental implants to artificial limbs (Science 311 515).

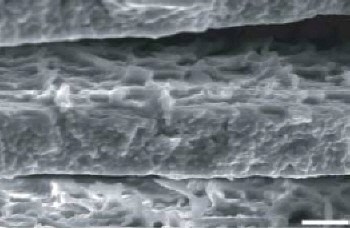

Although modern ceramics are strong, they are brittle and unsuitable for many applications. Researchers have therefore long envied natural materials like “nacre”, a component of mollusc shells. Nacre has a very intricate layered structure that makes the shells incredibly strong and tough (figure 1). A shell can absorb energy when hit, which makes it less likely to fracture.

However, previous techniques for mimicking the way seashells grow have been largely unsuccessful because their intricate structures need to be replicated at different length scales. Tomsia and colleagues have overcome this problem with their new technique, which copies the way that water freezes when impurities are present. Seawater, for example, contains dissolved salt and microorganisms that are expelled into channels between frozen ice crystals.

The team began by suspending a ceramic powder in water. They then froze the water, which causes the ice to grow in a fixed direction at a controlled velocity, trapping the ceramic particles between the growing ice crystals. Evaporating the ice leaves a porous structure — the scaffold — that has the same structure as the ice crystal layers. Finally, they filled the pores of the scaffold with an organic polymer or metal (figure 2).

The result is a tough, strong, dense ceramic composite in which the thickness and the number of layers can be controlled. According to the team, the materials could be used for artificial bone, heat exchangers for electronics, lightweight materials for cars or body armour, and high resistance machining tools.

“Concerning the biomedical field, we have been able to fabricate hydroxyapatite scaffolds strong enough to be considered for load-bearing applications for the first time — for example, prostheses and teeth implants,” explains Tomsia. “Hydroxyapatite is a calcium phosphate closely related to the mineral content of bone and is the best candidate for fabricating scaffolds for osseous tissue regeneration.”

The team is now trying to improve its technique and scale it up for industrial applications.