Superhydrophobic surfaces can be used to harvest small amounts of energy from the atmosphere, according to new research carried out by scientists at the Massachusetts Institute of Technology (MIT). The team has developed a device that uses jumping droplets of condensed water vapour to carry charges between two sets of metal plates. The device could be used as a handy tool in remote areas, to charge mobile phones or as an environmental sensor.

As the name suggests, superhydrophobic surfaces are highly effective at repelling water. This ability is down to their nano-scale topography, which limits contact – and therefore adhesive forces – between the surface and overlying liquids. Dominated by cohesive forces, droplets on these surfaces tend to ball up, forming beads that can easily roll away. Droplets of the right size – around 10–100 μm in diameter – can sometimes spontaneously jump, converting their excess surface energy into kinetic energy.

Jump start

These jumping droplets do not travel alone, however – they take a tiny electric charge with them. This effect – first noted by Nenad Miljkovic and colleagues in a paper last year – occurs through the interaction of free charges in the water with the superhydrophobic surface. “An electric double layer forms at the water/coating interfaces, and because of the fast jumping dynamics, charge separation can occur,” says Miljkovic. This, he explains, leaves a small positive charge on the droplets and a small negative charge on the surface.

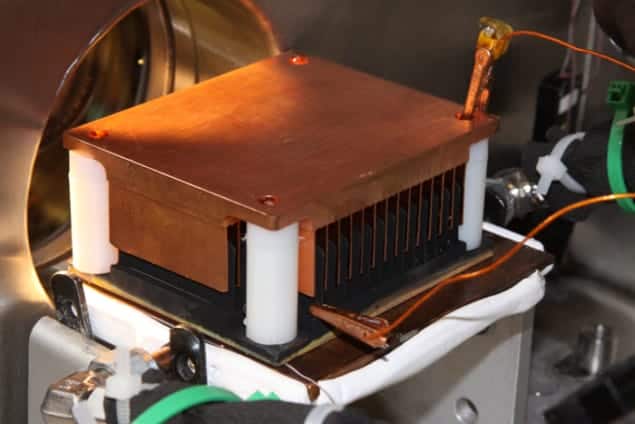

In their new study, Miljkovic and colleagues have put their earlier discovery to practical use – harvesting atmospheric energy. To do this, they created two sets of interleaved copper plates: one patterned to be superhydrophobic, the other hydrophilic. As water droplets condense on the first set of plates, they merge and leap across to the adjacent hydrophilic plates. With each drop, a small charge is transferred – building up a difference between the two sets of plates that can be used to power a circuit. The design is scalable: the larger the plates, the greater the overall charge transferred.

Remote tool

The concept does have its limitations though: it requires a humid environment, and the researchers’ prototype only provides 15 picowatts of power per square centimetre of plate. Despite this, Miljkovic is confident that the concept can be fine-tuned to harvest at least one microwatt per square centimetre. If achieved, the harvester might become a useful tool in remote regions. Such a device, 50 cubic cm in size, could charge a mobile phone in about 12 hours – an output comparable with other waste-energy harvesting solutions – and would also collect clean water. One specific application for this technology could be in automated environmental sensors, whose low power requirements might be covered by the morning dew alone. For more extensive uses, however, a cold sink – such as a flowing river – would be required to keep up the condensation.

Julie Crockett – a mechanical engineer from Brigham Young University who was not involved in the study – calls the work a “significant contribution to [the] field”, highlighting the potential for optimization of the superhydrophobic structuring. She adds, however, that “questions still remain about the longevity of the process, because of the jumping droplets coating the opposing hydrophilic wall, and the heat flux available for direct condensation of atmospheric moisture”.

“This finding is very exciting because it suggests that electricity could be passively harvested from the condensers found in many engineering systems,” comments Jonathan Boreyko – a mechanical engineer, formerly of the University of Tennessee, who will be joining Virginia Tech in the autumn – who was also not involved in this study. “It would be interesting to see how the performance is altered when using smooth parallel surfaces, which would remove the temperature gradient in the chilled superhydrophobic surface to enable more uniform jumping-drop condensation across the gap to the opposing electrode,” he adds.

Having demonstrated their prototype’s viability, the researchers are now refining their design, aiming for increased power output. They are also working on an aluminium version, which should be cheaper to make than their copper prototype.

The research is described in Applied Physics Letters.