Scientists at the Massachusetts Institute of Technology (MIT) have created novel optoelectronic fibres that contain metal, insulator and semiconductor layers. The fibres can be woven into a "spectrometric fabric" that could be used in devices such as photodetectors, and might also have applications in light-sensitive materials for clothing (M Bayindir et al. 2004 Nature 431 826).

Composites made of conductors, semiconductors and insulators are routinely used in electronic and optoelectronic devices. However, such devices are usually produced in elaborate wafer-based processes, which means that they are restricted to flat surfaces and small areas. In contrast, drawing fibre from a reel or tube is a much simpler technique. Moreover, it can be used to make long lengths of uniform fibres with good optical characteristics.

Yoel Fink and colleagues at MIT began by arranging a crystalline conductor (tin), an amorphous semiconductor (arsenic-selenium) and an insulator (polyetherimide) into a cylinder or “preform” about 20 centimetres long. The three components all have different refractive indices but similar melting temperatures, which means they can be processed under the same conditions.

The preform comprises a hollow air core, surrounded by a so-called omnidirectional or “perfect” dielectric mirror that is formed from eight pairs of alternating layers of arsenic-selenium and polyetherimide. Such a mirror — which was first demonstrated by Fink and co-workers in 1998 — is able to reflect light from all angles and with all polarisations, like an ordinary mirror, but it can also be tuned to only reflect at certain wavelengths.

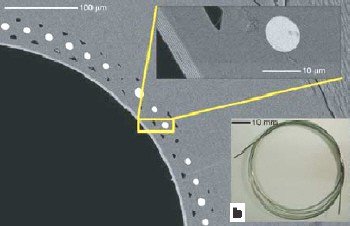

Next, the MIT team heated its preform in a furnace and drew it into a thread-like fibre hundreds of metres long. This step miniaturises the macroscopic cylinder but preserves its geometry to produce feature sizes smaller than 100 nanometres. Moreover, it creates intimate contacts between the semiconductor-insulator and metal layers. The whole fibre was then surrounded with cladding made from another polymer (figure 1).

The fibres produced are able to detect light along their length and if modified — by introducing a special photoconducting glass cylinder into the core — can generate an electrical response when illuminated. When woven into a fabric with a grid structure, the device is capable of localising point sources of light (figure 2). Furthermore, the direction of incoming light could be determined if layers of the fabric were overlapped.