Materials that expand and contract in response to changes in their environment have attracted considerable interest as building blocks for actuators or “artificial muscles” in miniaturized medical devices, robotics and smart textiles. Usually, these artificial muscle fibres contain exotic, non-textile materials such as graphene, carbon nanotubes or shape-memory alloys. Now, however, a team of researchers in China has succeeded in making them from ordinary cotton using a twisting and plying technique. The cotton muscles contract when exposed to water moisture, and the degree to which they twist and unwind compares well to muscles made from more complex materials.

Until now, most such actuators have been based on electrochemically-stimulated carbon-nanotube yarns, polymers that change shape when an electric field is applied, or shape-memory materials such as metals or polymers that exist in two phases and can therefore suddenly contract and expand at a given temperature. Researchers led by Zunfeng Liu of Nankai University in Tianjin had previously explored silk as a natural alternative, making moisture-sensitive artificial muscles and smart textiles from the protein-rich fibre of commercial silkworms. But since silk makes up less than 0.20% of the global textile market, they decided to investigate more widely-used natural fibres as well.

A logical choice

In many ways, cotton was a logical choice. It is widely available, accounting for nearly 40% of the world’s textile production in 2018. Cotton yarn is mechanically strong, with excellent hygroscopic (moisture-absorbing) properties, and its composition – mainly cellulose – makes it biocompatible with the human body. It is pleasant to wear, especially when the weather is warm and humid. It also softens when it absorbs moisture, is alkaline-resistant and tolerates a wide range of temperatures. All these properties make it a good candidate for crafting moisture-responsive smart textiles.

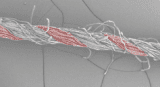

Liu and colleagues started out with ordinary shop-bought cotton from a commercial 17-ply 35-tex yarn. To make their muscle, they hung a load at the bottom of a strand of yarn and twisted it from the top using a motor (at a twist speed of 50 turns/minute). They then folded the twisted yarn in the middle and hung a load at this middle point to form a two-plied structure.

When exposed to water moisture, the cotton yarn expands in volume and untwists rapidly, providing 42.55°/mm of rotation at speeds of up to 720 rpm (as measured with a high-speed camera). Removing the water moisture reverses this process.

Physicists explain why clothes do not fall apart

Smart window made of cotton

To demonstrate the practical nature of their technique, Liu’s team designed a smart window from their yarn that spontaneously closes when it is wet and opens when it dries. The researchers say they would like to explore other real-world textile technologies applications for their cotton yarn muscle by improving its durability and sensitivity to moisture. “We are also looking into developing a technique to mass produce the muscle,” Liu tells Physics World.

The work is detailed in Chin. Phys. B, which is published by the Institute of Physics Publishing (IOPP).