Chris Walker looks at some of the uses of a novel amorphous diamond material.

Diamond — hard, sparkling and bright — has been revered for thousands of years as a gemstone. Nowadays it is also widely used in industry, with the first papers on “polycrystalline” diamond having been published as far back as 1911. However, it was not until 1971 that Sol Aisenberg and Ronald Chabot at Whitaker Corporation in the US discovered a new form of carbon that had the same form of bonding as diamond, but that was amorphous rather than crystalline. Created using ion-beam deposition, these thin films were coined “diamond-like carbon” (DLC) and are now used in everything from razor blades to computer hard disks.

Since then, researchers have worked hard to study the properties of DLC, which follows the contours of the surface rather than “filling in” the peaks and valleys. It is also highly smooth, its low friction arising from the relatively large proportion (65%) of diamond-like sp3 bonds between pairs of carbon atoms and the relatively small proportion (35%) of graphite-like sp2 bonds, which makes it amorphous rather than crystalline. Indeed, researchers at the Fraunhofer Institute in Germany have characterized different types of DLCs according to how they are formed and the percentage of sp2, sp3 and (sometimes) hydrogen bonds.

Another interesting feature of DLC is that it can be deposited onto substrate materials at temperatures of 200–300 °C, whereas polycrystalline materials have to be deposited at a much higher 800–1200 °C and so cannot be coated onto substrates that change phase below this temperature. Unfortunately, it is not easy to produce useful DLC films that are thicker than about 3–5 µm because the high temperatures used to make them generates stresses inside the materials, which then expand on their substrates. Now, however, Diamond Hard Surfaces Ltd has developed and patented a process for producing a material that bridges the gap between traditional DLCs and polycrystalline diamond.

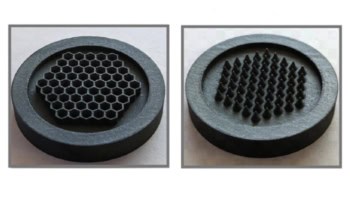

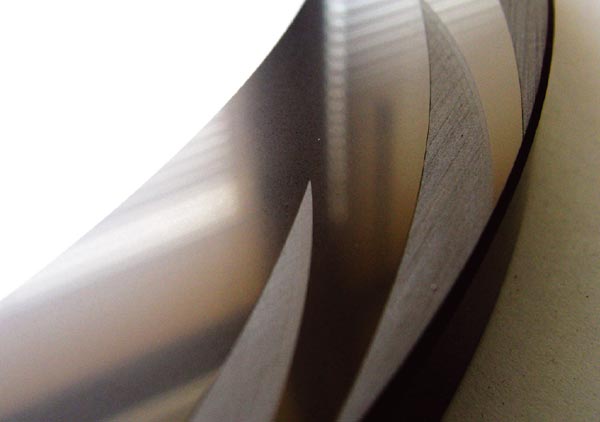

The result is a hard, low-friction amorphous material, named Adamant, that can be applied in thicknesses of 40 µm and beyond, which is an order of magnitude higher than other technologies. Created using a patented plasma-assisted chemical vapour deposition (CVD) process operating at less than 100 °C, the material has a hardness of 3500–4000 on the Vickers hardness (HV) scale as a result of its very high proportion (~99%) of sp3 bonds. (The hardness of tungsten carbide, in comparison, is only 2000 HV.) The process uses ultra-high-vacuum conditions and involves splitting up carbon-containing molecules, with the resulting ions being accelerated towards the surface of a substrate on which tetrahedrally bonded carbon (i.e. diamond) is formed.

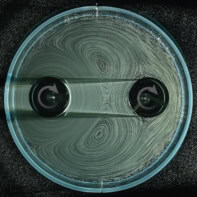

Adamant has many potential applications, particularly those where bulk materials (e.g. tungsten carbide) and coatings (e.g. hard chrome) are used in thick layers of up to 100 µm. Indeed, since Adamant is 12–15 times as wear-resistant as tungsten carbide and about twice as hard, any film made from it will last far longer than a tungsten-carbide film of the same thickness. That hardness makes the material useful for oil and gas firms that send drill bits and other moving parts long distances down underground shafts to reach the source of fuel. Adamant is also being used to make everything from long-life cam shafts for the motor-sport industry, where engines are not allowed to be opened up between races, to sharp, longer-lasting knives to cut plastic sheets as they roll off an industrial production line.

Adamant, which is transparent to infrared light, could also be used in the defence and aerospace industries. For example, the infrared light that missiles use to guide themselves to a target is usually directed through a sapphire window. Coating the sapphire with Adamant would make it much tougher and reduce the possibility of the window becoming damaged due to the abrasive effect of air rushing past. Another advantage is Adamant’s “green” credentials: it does not need much energy to be made, uses harmless precursors and does not need any energy-intensive pre- and post-processing.

Owing to the low deposition temperature, the material can be coated on a variety of substrates, such as copper, aluminium, silicon carbide, tungsten carbide, titanium and even plastics, such as polyetheretherketone. The process is scalable and our company has just completed a new facility to make Adamant in large enough quantities to satisfy customer demand. There is plenty that we do not yet know about the boundaries between amorphous carbon and polycrystalline diamond, and our company is hoping to fill that gap.