A new thermoregulating textile keeps its wearers comfortable with a minimal amount of energy input thanks to a conductive polymer that can be modified to adjust how much infrared radiation it sheds. According to the textile’s developers at the University of Chicago, North Carolina State University and Duke University (all in the US), the new “wearable variable-emittance device”, or WeaVE, could be used to make next-generation smart thermal management fabrics.

Many animals are good at manipulating infrared (IR) radiation to heat themselves up and cool themselves down. Saharan silver ants, for example, dissipate excess heat thanks to triangular hairs on their bodies that reflect differing amounts of near-IR rays depending on the position of the Sun. Human bodies, in contrast, absorb and lose heat mainly through IR radiation with a wavelength of 10 microns, and our skin is not capable of controlling this wavelength range in real time to help us regulate body temperature. Researchers are therefore developing textiles that can do this for us.

Fabric switches between two states

The new WeaVE device consists of three layers: an active layer made of a conducting polymer called polyaniline (PANI); metallized nylon; and a semi-solid electrolyte. When a small voltage is applied to this layered structure, the active material switches between a transmissive dielectric state and a lossy metallic state. Each state has a different emissivity, so by switching between them, the amount of thermal radiation the fabric puts out can be adjusted to make it either heat-emitting (cooling) or heat-shielding (heating).

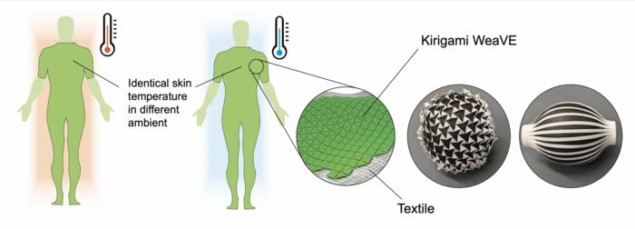

“The textile can thus keep the wearer comfortable by adjusting how much body heat is retained and how much is radiated away,” explains Chicago’s Po-Chun Hsu, who led the development team together with Jie Yin of NC State. “In this way, the user would feel the same skin temperature regardless of the external temperature.”

Thermoregulation is “adaptive”

One major advantage of the WeaVE is that the electrochemical tuning used to modify its radiative heat transport requires only a small amount of energy input. This type of thermoregulation is termed “adaptive”, meaning that it relies on modulating the material’s heat transfer coefficient, and it uses far less energy than “active” technologies that use electric heat or recirculating water to generate or pump thermal energy. As a result, the energy required to maintain the heat balance is virtually zero. A further advantage is that the metallized nylon in the fabric is cut in a kirigami-style pattern, which allows it to stretch and move with the user’s body while fully preserving the connections and configuration of the electrochemical cell.

The WeaVE’s flexibility and low energy use means it could be employed in sustainable, next-generation textiles and fabrics that allow users to adapt to their environments, Hsu says. “As thermal comfort is a highly individualized and subjective concept, it would be beneficial if the cooling/warming effect is tailored for everyone based on their feelings and the surrounding environment,” he tells Physics World. “We also hope that this work could inspire future research on both the materials science of conducting polymers and the engineering of smart wearable personal thermoregulation devices.”

‘Janus textile’ could keep you warm and cool you down

The researchers are now working towards demonstrating other electrochemically tuneable thermal materials based on conducting polymers. “The fundamental studies of polymer physics and light-matter interaction of the electrochromic mechanisms are also our main focus, which is not only scientifically interesting but can lead us towards higher-performance polymers,” Hsu says.

They detail their present work in PNAS Nexus.