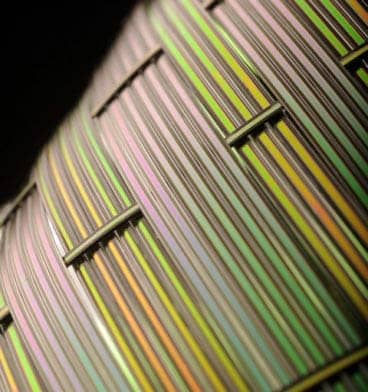

Researchers at the Massachusetts Institute of Technology (MIT) in the US have created a new generation of fibres that, they claim, can both detect and produce sound. The fibres, which contain a tree-ring structure of piezoelectrics, electrodes and polymers, could have a range of applications that include medical imagers and microphones weaved into clothing.

Conventional fibre optics, which transmit light across their length through a process of total internal reflection, have become crucial for modern industry. Without them, we would have none of the long-distance, high-bandwidth communications that we take for granted today.

But over the past decade physicists, including those at MIT, have begun to develop fibres that are more complex than just solid glass. One example is photonic-crystal fibres, which contain holes running throughout their length to exhibit unusual optical properties. Unlike conventional fibres, photonic-crystal fibres can carry light of high power in the infrared, which is particularly useful for cutting tissue in medicine.

Some fibres have even been built to contain a range of conductors, insulators and semiconductors – suggesting the future might see many electronic devices make the transition from chip to fibre.

Pole position

Now, MIT’s Yoel Fink and colleagues have succeeded in what might be the most challenging fibre construction yet: a piezoelectric surrounded by electrodes. Piezoelectrics – materials that respond to stress with a generated electric field, and vice-versa – are tricky to draw into fibres. The process requires heating, and this tends to make a piezoelectric mix with adjacent materials, such as those making the electrodes.

Moreover, once drawn, many piezoelectrics have to be “poled” – that is, have internal molecules lined up in a strong electric field – but metal electrodes are not uniform enough to do this effectively.

The MIT group solved these problems with electrodes made of a conducting polymer, which avoids mixing and which can supply large electric fields. The researchers began with a “preform” of the fibre about the size of a torch, and then heated it to over 200 °C while stretching it to over a thousand times its initial length. Once drawn, they supplied a voltage of several kilovolts to align the molecules and restore the piezoelectric effect.

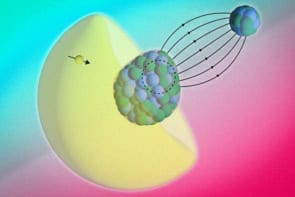

The resultant fibres can be made to act as a loudspeaker by passing an electric field between the two electrodes around the fibre, which causes the crystal to change shape and vibrate, emitting sound. Conversely, the fibres can act as a microphone because sound makes the crystals vibrate, putting them under stress and so generating an electric field. In both cases, the fibres operate from kilohertz to megahertz frequencies.

Smart clothes

“This is very interesting and innovative research that can have important applications in smart clothes, flexible and wearable sonic-wave detectors, high-performance stereo systems, and sensors and transducers,” says Zhong Lin Wang, a researcher at the Georgia Institute of Technology, US, who showed in 2008 how piezoelectrics could harvest energy in shoes and fabric. “This could inspire much new research in the field.”

Indeed, the MIT group has a host of applications up its sleeve. Wrapped round the body, the fibres could provide a means to map the inside of a body using ultrasound. On much larger scales, the fibres could be strewn through the ocean to monitor water-current flows.

“This paper is a first step to prove the principle of multi-material piezoelectric fibres,” explains MIT group member Zheng Wang. “We’re going to tailor our fibres for many applications…[and] we’re also pursuing ideas of integrating piezoelectric elements with other functional-fibre devices already demonstrated in our group.”

The research is published in Nature Materials.