The UK firm Cryogenic claims to be the first to deliver a superconducting magnet and cryogenic measurement system that does not require a constant supply of liquid helium in order to operate at very low temperatures. Instead, the "cryogen-free" or "dry" system is cooled using Gifford–McMahon (GM) coolers, which are closed systems that do not need to be constantly topped up with liquid helium. To avoid this, GM coolers rely instead on the compression and expansion of a small quantity of helium gas.

According to the company, the system is designed to allow the magnetic and thermal properties of samples to be investigated at temperatures down to 300 mK while subjecting them to magnetic fields as high as 17 T. Unlike most other cryogenic measurement systems, the new device does not rely on liquid helium to cool either the sample or the magnetic coils. As well as making it easier to maintain than traditional liquid-cooled instruments, the system can also be used by researchers who do not have easy access to liquid helium, for example those in the developing world.

Cryogenic has already delivered its first 17 T system to Stockholm University, and according to the firm’s director of sales Renny Hall, it will soon ship systems to customers in India and Denmark.

Cryogenic’s previous record for a completely cryogen-free system is its 14 T system, which uses one GM cooler. To get that extra 3 T, the company added a second GM cooler that allows that magnets to be operated at higher currents. The system can operate at fields of up to 6 T on one cooler, with the second required to reach higher fields.

The firm has also made improvements to the design of the magnetic coils in order to reduce the stresses caused by such high magnetic fields, thus further boosting the amount of current that the superconducting coils can carry. Most 17 T magnets are cooled to 2 K, but through careful design the new system could work at 4 K, where it could be operated efficiently using the GM coolers.

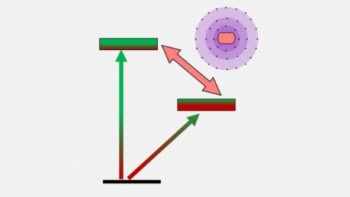

The GM coolers can get the sample temperature down to about 1.6 K, and then it can be further chilled to 300 mK using a helium-3 insert, which cools by condensing a small quantity of helium-3 gas. The system is supplied with both a resistivity and Hall-effect probe with sample rotation, and an AC-susceptibility probe with a compensated pair of pick-ups. The magnetic field can be adjusted with a resolution of ±50 mT and the instrument can be supplied with an optional vibrating sample magnetometer for the measurement of DC magnetic moments, plus an optional AC calorimeter for making heat-capacity measurements.

Plug-and-go systems

According to managing director Jeremy Good, a physicist who founded Cryogenic in 1970 and began developing cryogen-free magnets in the mid-1990s, dry cryogenics is facilitating a huge change in how low-temperature physics is being carried out. “Buying, storing and recycling liquid helium is a huge operation,” he says. While researchers in the West have ready access to suppliers and liquefaction facilities, this is not always the case in the emerging economies of eastern Europe, India and China, where dry cryogenics is often the only option for researchers. Good believes that a system that simply plugs into the wall will be a boon to researchers in these regions.

Another import trend, according to Good, is the “tremendous interest in developing new magnetic materials for data storage”. While commercial data-storage devices must operate at room temperature, preliminary research on new materials is often done on very cold samples using the high magnetic fields generated by superconducting magnets. According to Good, a lot of the researchers who are now studying such materials have little prior experience of liquid-helium cryogenics — chemists, for example.

As a result, a dry cryogenics system is very attractive to those who are new to the technique. Good also believes that there is a growing concern about a looming shortage of helium and of rising prices. “Researchers are slowly coming round to dry systems,” he says.