Researchers at Linköping University in Sweden have developed a new fluid electrode and used it to make a soft, malleable battery that can recharge and discharge over 500 cycles while maintaining its high performance. The device, which continues to function even when stretched to twice its length, might be used in next-generation wearable electronics.

Futuristic wearables such as e-skin patches, e-textiles and even internal e-implants on the organs or nerves will need to conform far more closely to the contours of the human body than today’s devices can. To fulfil this requirement of being soft and stretchable as well as flexible, such devices will need to be made from mechanically pliant components powered by soft, supple batteries. Today’s batteries, however, are mostly rigid. They also tend to be bulky because long-term operations and power-hungry functions such as wireless data transfer, continuous sensing and complex processing demand plenty of stored energy.

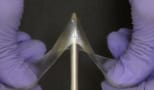

“To overcome these barriers, researchers led by the Linköping chemists Aiman Rahmanudin and Saeed Mardi decided to rethink the very concept of battery electrode design.” Instead of engineering softness and stretchability into a solid electrode, as was the case in most previous efforts, they made the electrode out of a fluid. “Bulky batteries compromise the mechanical compliance of wearable devices, but since fluids can be easily shaped into any configuration, this limitation is removed, opening up new design possibilities for next-generation wearables,” Rahmanudin says.

A “holistic approach”

Designing a stretchable battery requires a holistic approach, he adds, as all the device’s components need to be soft and stretchy. For example, they used a modified version of the wood-based biopolymer lignin as the cathode and a conjugated poly(1-amino-5-chloroanthraquinone) (PACA) as the anode. They made these electrodes fluid by dispersing them separately with conductive carbon fillers in an aqueous electrolyte medium consisting of 0.1 M HClO4.

To integrate these electrodes into a complete cell, they had to design a stretchable current collector and an ion-selective membrane to prevent the cathodic and anodic fluids from crossing over. They also encapsulated the fluids in a robust, low-permeability elastomer to prevent them from drying up.

Designing energy storage devices from the “inside out”

Previous flexible, high-performance electrode work by the Linköping team focused on engineering the mechanical properties of solid battery electrodes by varying their Young’s modulus. “For example, think of a rubber composite that can be stretched and bent,” explains Rahmanudin. “The thicker the rubber, however, the higher the force required to stretch it, which affects mechanical compliancy.

“Learning from our past experience and work on electrofluids (which are conductive particles dispersed in a liquid medium employed as stretchable conductors), we figured that mixing redox particles with conductive particles and suspending them in an electrolyte could potentially work as battery electrodes. And we found that it did.”

Rahmanudin tells Physics World that fluid-based electrodes could lead to entirely new battery designs, including batteries that could be moulded into textiles, embedded in skin-worn patches or integrated into soft robotics.

Novel ‘glassy gel’ materials are strong yet stretchable

After reporting their work in Science Advances, the researchers are now working on increasing the voltage output of their battery, which currently stands 0.9 V. “We are also looking into using Earth-abundant and sustainable materials like zinc and manganese oxide for future versions of our device and aim at replacing the acidic electrolyte we used with a safer pH neutral and biocompatible equivalent,” Rahmanudin says.

Another exciting direction, he adds, will be to exploit the fluid nature of such materials to build batteries with more complex three-dimensional shapes, such as spirals or lattices, that are tailored for specific applications. “Since the electrodes can be poured, moulded or reconfigured, we envisage a lot of creative potential here,” Rahmanudin says.