Honeycomb lattices and fractal structures are found in a range of biological materials. Now, scientists in the US, the UK and France have combined the two types of pattern to create a strong and lightweight material that could be used in a range of applications, from aerospace to medicine. While the structures were made with centimetre-sized unit cells, the team believes that similar materials could be made on the nanoscale using carbon nanotubes.

Hexagonal honeycomb patterns often appear in nature, where strength, rigidity and lightness are called for. The shells of armadillos, the beaks of birds and, of course, the wax cells built by bees are just a few examples of nature’s honeycombs. Engineers have long known about the honeycomb’s strength and low density, and the structure has been used in applications as varied as satellite components and the scaffolding for growing new heart tissue.

Now, Ashkan Vaziri and colleagues at Northeastern University, along with researchers at the University of Oxford and the Université de Lyon, have shown that fractal-like structures based on honeycombs are even more resistant to deformation than conventional honeycomb materials.

Hierarchical structures

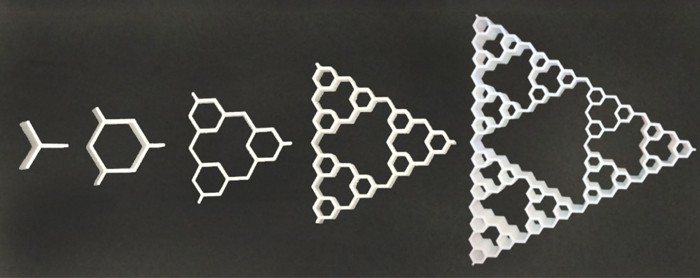

Fractals – in which the same patterns appear on different length scales – are also found in a variety of naturally occurring materials, including the buds on certain types of broccoli, pinecone seeds and nautilus shells. “Hierarchical structures are ubiquitous in nature and can be observed at many different scales in organic materials and biological systems,” explains Vaziri. Honeycombs on their own are not fractals because their characteristic shape only occurs on one length scale. However, a hierarchical fractal structure can be built upon a hexagonal honeycomb by successively replacing each vertex of three edges with another, smaller hexagon (see the image below).

Vaziri and collaborators looked at how the mechanical properties of these hierarchical hexagonal honeycombs varied as a function of how many times the fractal order was repeated. The team used both MATLAB computer models and experimental testing to study the structural performance of the hierarchical hexagonal honeycombs. Specifically, the researchers looked at the elements of the structure that can undergo stretching, shear and bending. “Our goal is to develop novel, hierarchical structures that are far superior to the classical cellular structures in terms of their mechanical response,” Vaziri told physicsworld.com.

Reaching a limit

The computer simulations focused on the elastic modulus of each structure, which measures a material’s ability to resist deformation. To make a meaningful comparison between structures comprising different numbers of hexagonal hierarchies, the team adjusted the thickness of each structure to ensure that they all had the same density.

“Generally, increasing the density of the cellular structure while preserving its topology improves the mechanical properties of the structure,” Vaziri explains. “To solely investigate the effect of hierarchical order on the mechanical properties of the hierarchical structure, we preserve the relative density while increasing the hierarchical order.”

The simulations predict that the elastic moduli of the structures increase with hierarchical order, up to a certain threshold. Furthermore, the calculations suggest that materials with desirable elastic moduli can be manufactured without having to resort to extremely high orders of hierarchy. This is good news from a practical point of view, because it would be difficult to achieve high orders of hierarchy using today’s 3D printing technologies.

Making it real

The next step for Vaziri’s team was to test its findings in the lab. The researchers used a 3D printer to manufacture extruded polymer shells of five honeycomb structures, each with a successively higher order of hierarchy. The thickness of the honeycomb walls was maintained at 2 mm because of limitations of the 3D printing process. To maintain a constant density, the size of the unit cells was adjusted instead of the thickness.

The hexagonal edge lengths of the extruded structures ranged from 0.6 to 2.2 cm. The researchers tested the compressive response and elastic modulus of each structure, recording how each structure’s resistance to deformation varied as a function of its hierarchy. The results revealed that, as predicted by the simulations, structures with a higher order of hierarchy had increasingly larger elastic moduli, to a certain limit.

Even though Vaziri and his team focused on unit cells that were on the centimetre length scale, they are confident that their findings can be applied to smaller scales. “The unit cells of the hierarchical honeycombs can be built with single- or multi-walled carbon nanotubes,” Vaziri claims. Deformation-resistant structures assembled from carbon nanotubes would have widespread applications in biological engineering and materials science.

The structures are described in Physical Review Letters.