Available to watch now

Discover the realities and requirements of catalyst development for fuel cell applications

Want to learn more on this subject?

Heavy-duty vehicles (HDVs) powered by hydrogen-based proton-exchange membrane (PEM) fuel cells offer a cleaner alternative to diesel-powered internal combustion engines for decarbonizing long-haul transportation sectors. The development path of sub-components for HDV fuel-cell applications is guided by the total cost of ownership (TCO) analysis of the truck.

TCO analysis suggests that the cost of the hydrogen fuel consumed over the lifetime of the HDV is more dominant because trucks typically operate over very high mileages (~a million miles) than the fuel cell stack capital expense (CapEx). Commercial HDV applications consume more hydrogen and demand higher durability, meaning that TCO is largely related to the fuel-cell efficiency and durability of catalysts.

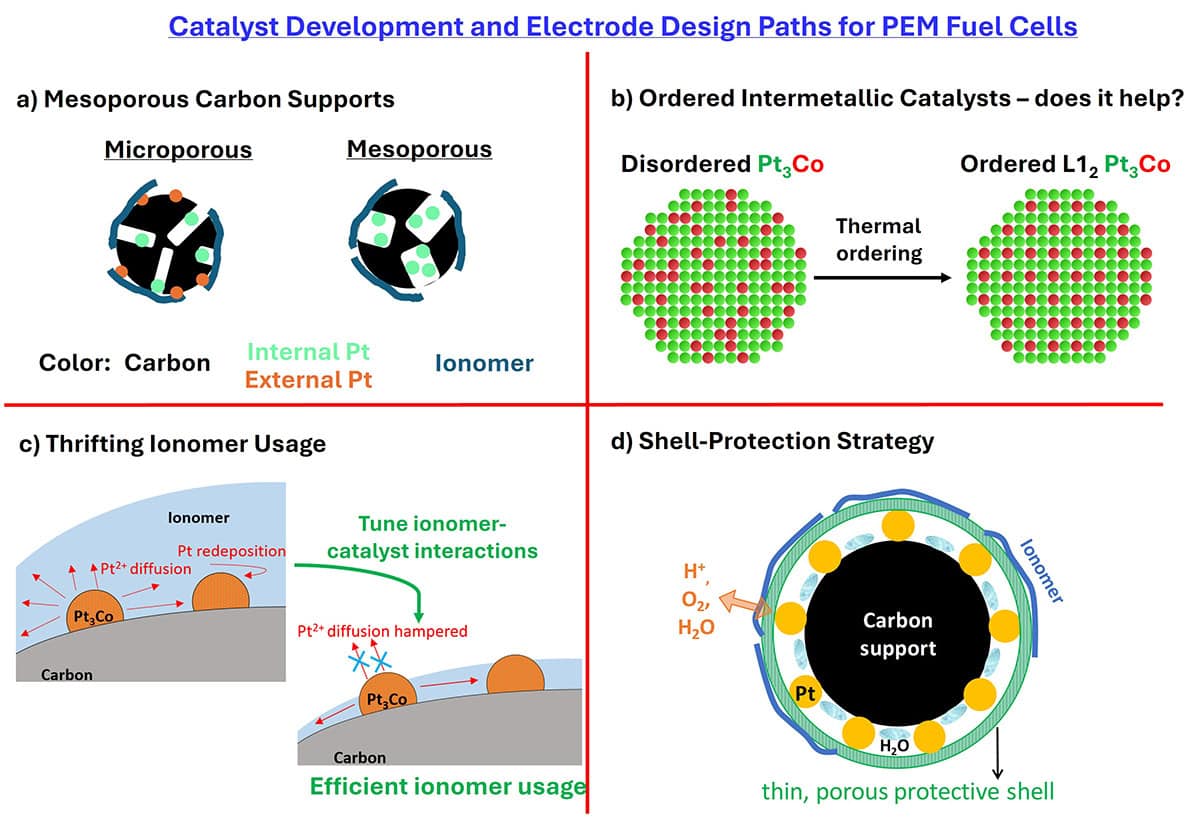

This article is written to bridge the gap between the industrial requirements and academic activity for advanced cathode catalysts with an emphasis on durability. From a materials perspective, the underlying nature of the carbon support, Pt-alloy crystal structure, stability of the alloying element, cathode ionomer volume fraction, and catalyst–ionomer interface play a critical role in improving performance and durability.

We provide our perspective on four major approaches, namely, mesoporous carbon supports, ordered PtCo intermetallic alloys, thrifting ionomer volume fraction, and shell-protection strategies that are currently being pursued. While each approach has its merits and demerits, their key developmental needs for future are highlighted.

Want to learn more on this subject?

Nagappan Ramaswamy joined the Department of Chemical Engineering at IIT Bombay as a faculty member in January 2025. He earned his PhD in 2011 from Northeastern University, Boston specialising in fuel cell electrocatalysis.

He then spent 13 years working in industrial R&D – two years at Nissan North American in Michigan USA focusing on lithium-ion batteries, followed by 11 years at General Motors in Michigan USA focusing on low-temperature fuel cells and electrolyser technologies. While at GM, he led two multi-million-dollar research projects funded by the US Department of Energy focused on the development of proton-exchange membrane fuel cells for automotive applications.

At IIT Bombay, his primary research interests include low-temperature electrochemical energy-conversion and storage devices such as fuel cells, electrolysers and redox-flow batteries involving materials development, stack design and diagnostics.