Could a graphene coating make surgical masks easier to sterilize and re-use? According to a team of researchers at The Hong Kong Polytechnic University (PolyU), the answer is yes. Led by Guijun Li of PolyU’s industrial and systems engineering department, the team developed a laser manufacturing process that deposits a few layers of the carbon sheet onto commercially-available non-woven masks. The coating makes the masks superhydrophobic, which reduces the chances of infectious drops adhering to them, while graphene’s strong light-absorption properties makes it possible to sterilize them with exposure to sunlight.

To curb the COVID-19 pandemic, health officials are recommending that citizens wear masks in public, especially in situations where physical distancing is difficult or impossible. While any mask is better than no mask at all, the consensus is that surgical masks made from nonwoven polymer fibres are among the best types available for widespread use outside hospital settings.

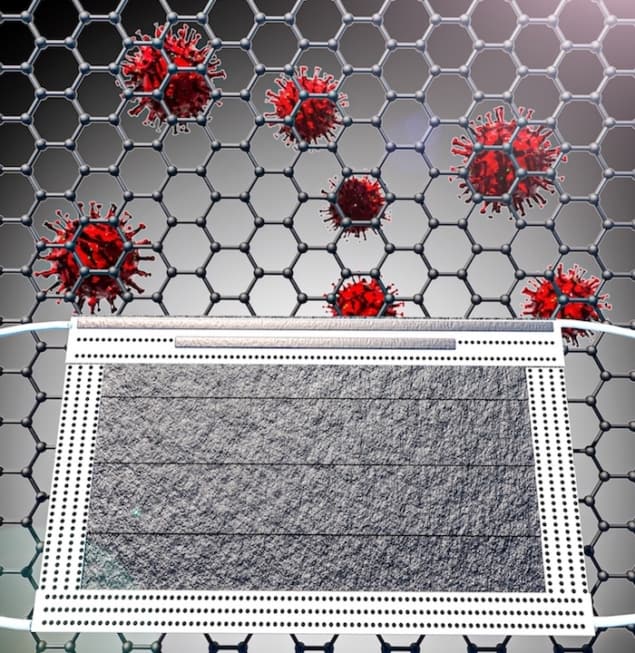

Such masks do, however, have limitations. While they help prevent viruses (including SARS-CoV-2, the cause of the current pandemic) from entering the wearer’s nose and mouth via droplets generated when an infected person sneezes, coughs or talks, virus-laden droplets tend to remain on the mask. This means that masks must either be discarded after each use or sterilized before re-use. Neither option is attractive, since polymer-based masks are difficult to sterilize even with steam, while discarding them poses an environmental challenge. The estimated 40 million pieces of protective gear produced worldwide every day amount to a daily 15,000-tonne mountain of waste – much of which must be incinerated, adding to carbon emissions.

Superhydrophobic surfaces

One possible solution lies in making masks that are superhydrophobic, meaning that they strongly repel aqueous liquids. Researchers have previously made advanced superhydrophobic nanostructured surfaces out of materials such as fluorinated polymers, metallic nanowires and, most recently, graphene. Some of these materials could have medical applications, but according to Li, their potential has not been fully explored. “To the best of our knowledge, such materials have never been used on surgical masks before,” he says.

Li and colleagues began by synthesizing graphene using a low-cost laser technique that heats up precursors such as polyimide, SPEEK and Bakelite. They made the carbon sheet superhydrophobic by controlling the parameters during the laser processing.

Next, they used a new technique, developed in their lab, to deposit a few layers of this graphene onto commercial surgical masks. This new process is known as dual-mode laser-induced forward transfer (LIFT), and it uses a pulsed laser beam with a pulse duration of 10 ns. This short pulse length means that the momentum of the photons is high enough to transfer the graphene without significantly increasing the mask’s temperature – an important point, Li explains, because the melting point of the polymer fibres in the mask is only 130 °C. The LIFT method is also compatible with a roll-to-roll system, meaning that it can easily be integrated with existing automated mask manufacturing production lines, he adds.

Water droplets roll off

Since the graphene is superhydrophobic, it is self-cleaning, like a lotus leaf, Li tells Physics World. Indeed, water droplets freely roll off the surface of the mask before they have time to adhere to it.

Another benefit, the researchers say, is that they can sterilize their graphene-coated masks simply by exposing them to sunlight for 40–100 seconds. This is possible because graphene absorbs more than 95% of light across the solar spectrum from 300–2500 nm, so the coated masks quickly increase in temperature, reaching 70°C after 40 seconds of solar illumination and more than 80°C after 100 seconds. That is high enough to inactivate most types of viruses, meaning that the mask can then be reused or (if damaged) safely recycled. In contrast, masks without a graphene coating do not show this photothermal effect, since they absorb sunlight only weakly. Even after 5 minutes of solar illumination, their temperature does not exceed 50°C, Li explains.

Graphene filters go large

Testing for antiviral capacity

Valentina Palmieri, a researcher at Italy’s Institute for Complex Systems who was not involved in the PolyU study, commends Li’s team for developing a way to transfer graphene onto surgical masks, and says that using the light absorbance properties of graphene to recycle and sterilize them is “a feasible approach”. As the author of a recent paper entitled “Can graphene take part in the fight against COVID-19?”, Palmieri points out that a similar light-based process could also be used to sterilize graphene-coated environmental air filters. She also notes that large surface area graphene has already been used to construct sensors embedded in textiles, as well as platforms that use antibody conjugation to diagnose disease. In some cases, the nanomaterial itself showed antiviral capacity.

The PolyU team, who report their work in ACS Nano, say they have successfully tested the LIFT graphene against E. coli bacteria. They now plan to test their graphene-coated masks against viruses, including SARS-CoV-2.