Testing the effect of new drugs on heart tissue could become more straightforward, thanks to new research by a team at Harvard University’s Wyss Institute. The researchers have developed a faster method for manufacturing a “heart-on-a-chip” that can be used to test the reaction of heart tissue to external stimuli (Biofabrication 10 025004).

“One of the major challenges in drug discovery and development is failure at the clinical testing stage due to cardiac toxicity,” explained co-lead author Lisa Scudder. “A way to overcome this is to develop new preclinical tests for new drugs using engineered tissues that mimic the native organs of the human body such as the heart.”

Scudder and colleagues are working to build improved platforms to test the safety and efficacy of new drugs, by engineering functional units of human organs using human tissue. For the heart-on-a-chip, they aim to build a tissue that is as contractile and organized as the human heart, enabling measurement of contractile force – a major determinant of heart pumping performance.

“The chip we’ve made is an extension of our previous work, which established a new platform using the miniaturized structural formation of cardiac muscle on a cantilever of hydrogel,” said co-lead author Janna Nawroth. “We use hydrogel because its mechanical properties are similar to the extracellular matrix of the heart. This pre-patterned substrate results in an organized growth of cardiac muscle. The end goal is to put these tissue structures into a microfluidic environment, where we can closely regulate and monitor the flow of the new drug being tested.”

For use in drug development and biomedical research within industry, the chips need to be amenable to mass manufacturing. The existing way of engineering cardiac tissues involves using photomasks, stamping, and manually moulding gelatin to create patterns in the hydrogel. This approach takes too long and is not practical for large-scale chip manufacturing.

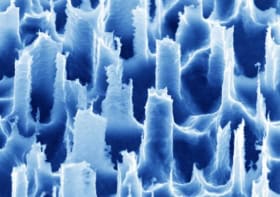

“Our new heart-on-a-chip fabrication method uses a UV laser to pattern the hydrogel, employing riboflavin to sensitize the gel for optical ablation,” explained Scudder. “This patterning method then allows the cardiac cells to align into organized laminar tissue structures like in the native heart.”

This UV micropatterning method creates features on the gel much faster than traditional moulding techniques, but with the same resolution and reproducibility. It can generate aligned cardiac tissue and muscular thin films, which beat and contract in response to external stimuli like electrical pacing. As well as being scalable, the new fabrication scheme doesn’t alter the properties of the hydrogel and is up to 60% faster than the old process.

This method could also be used to manufacture other organs-on-a-chip, such as a brain or skeletal muscle-on-a-chip. “In the future, we hope to expand on this fabrication method to mimic disease states like fibrosis, or to create more complex three-dimensional tissue structures that could provide new tools for the preclinical drug development process,” said Scudder.