Sweden’s Treesearch initiative is partnering with large-scale research facilities like the MAX IV synchrotron laboratory to realize sustainable products based on materials from the forest. Joe McEntee finds out more

Collaboration, at scale, provides the raison d’être for Treesearch, an ambitious Swedish R&D initiative that brings together a cross-disciplinary cohort of scientists and engineers from academia, industry and government agencies within an open research platform focused on the “future bioeconomy”. Zoom in a little and it’s evident this over-arching mission translates into a broad-scope remit, one that spans fundamental science, technology innovation and competence-building to realize a new generation of advanced materials from the forest.

Collectively, there are more than 510 researchers (and 190 projects) represented within the Treesearch consortium, with the work broadly carved up across four thematic areas: wood and wood components (structure and modification); biorefinery for materials and chemical systems; fabrication of material systems; and advanced material concepts (design and functionality). “One of Treesearch’s core priorities is to help our academic and industry stakeholders to access advanced research infrastructures across Sweden,” explained Daniel Söderberg, Treesearch director and head of the department of fibre and polymer technology at the Royal Institute of Technology (KTH), Stockholm.

Equally important, he told delegates at this summer’s Treesearch Insight conference in Lund, is “opening the door to the specialist technical support needed to make best use of such cutting-edge experimental infrastructures”. The facilities in question range from the National Center for High-Resolution Electron Microscopy (nCHERM) at Lund University (in Sweden’s south-western corner) to the X-ray Microtomography Laboratory at Luleå University of Technology (1500 km away in the country’s north-east) plus an extensive network of specialist research hubs in between – among them the Wallenberg Wood Science Center and the Research Institutes of Sweden (RISE).

Synchrotron insights

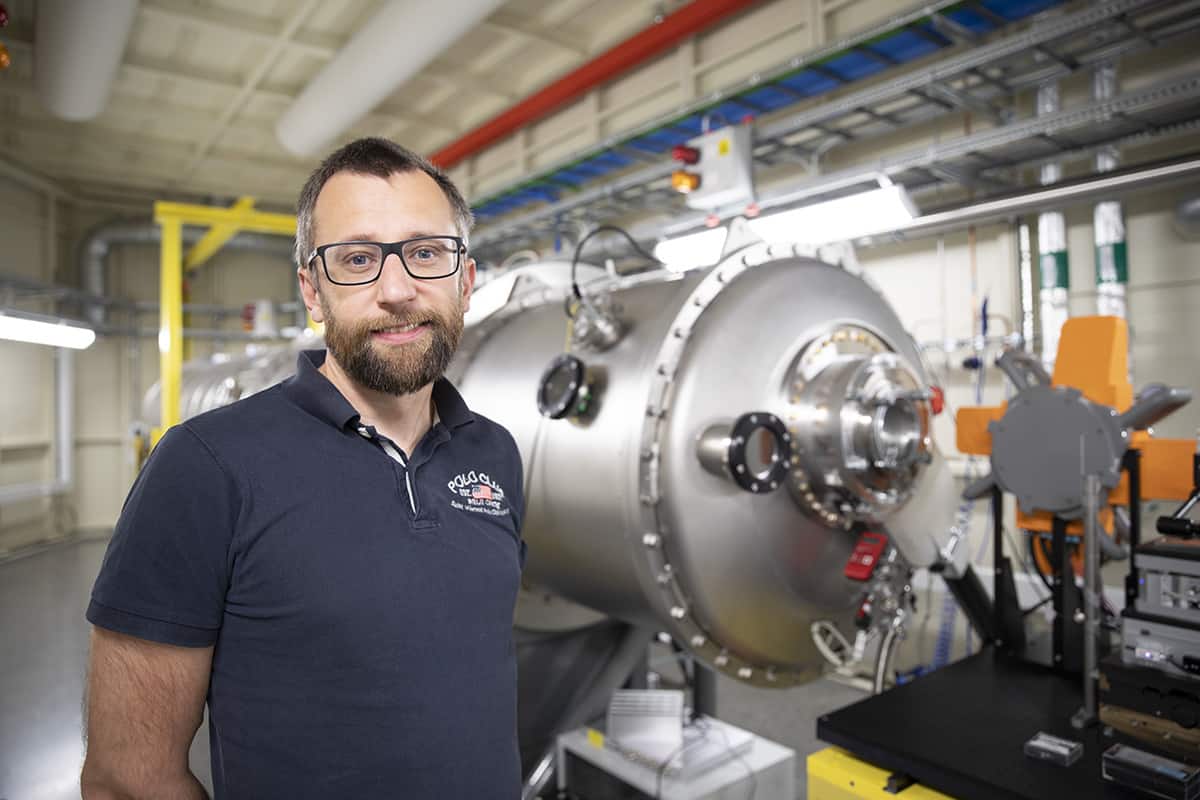

A flagship Treesearch partner in this regard is the MAX IV synchrotron radiation facility in Lund. Globally significant, MAX IV is one of an elite cadre of large-scale X-ray sources that is shedding light on the structure and behaviour of matter at the atomic and molecular level across a range of fundamental and applied disciplines – from clean-energy technologies to pharma and healthcare, from structural biology to quantum science and cultural heritage.

In terms of core building blocks, this fourth-generation light source – which was inaugurated in 2016 – consists of a linear electron accelerator plus 1.5 and 3 GeV electron storage rings (with the two rings optimized for the production of soft and hard X-rays, respectively). As well as delivering beam to a short-pulse facility, the linac serves as a full-energy injector to the two storage rings which, in turn, generate X-ray photons that are extracted for user experiments across 16 specialist beamlines.

The latest addition to MAX IV, the ForMAX beamline, opened for user experiments in November 2022 and is dedicated to research on sustainable wood-based materials from the forest (though it will also support X-ray studies on other complex materials such as food, textiles and bone). Collaboration is once again front-and-centre, with the 100 million SEK (£7.5 million) construction costs of ForMAX funded by the Knut and Alice Wallenberg Foundation (a Swedish philanthropic organization that supports scientific research), while the 80 million SEK operational budget over 10 years is covered by commercial partners (mainly companies in the pulp and paper industry). ForMAX beamtime is allocated accordingly, with 50% of the experiments to be conducted by Treesearch members and the remainder offered via open calls to the wider research community.

“Through ForMAX, Treesearch academia and industry partners have a dedicated access point to the MAX IV research environment,” explained Söderberg. “As such, the beamline underpins a broad, unique competence in synchrotron science and will, over time, enable the development of sustainable wood-based products to replace today’s plastic products.”

Into the woods

For the most part, ForMAX beam time will support fundamental and applied studies on wood-based materials, providing in-situ structural characterization from nanometre to millimetre length scales by combining full-field X-ray microtomographic imaging, small- and wide-angle X-ray scattering (SWAXS) and scanning SWAXS imaging in a single instrument. For context, the ForMAX microtomography system uses incident X-rays to generate planar cross-sections of a sample that can be used to recreate a virtual 3D model (at length scales from 1 mm down to 1 micron). The SWAXS set-up, on the other hand, relies on two discrete detectors to collect X-ray spectra scattered from a sample at different angles: WAXS yielding structural information down to the 1 nm scale, with SAXS used for soft-matter studies – of polymer, colloidal and biological assemblies, for example – up to several hundred nm in size.

That versatility will enable researchers to investigate wood’s structural hierarchy and composite nature – from the fibre network and cellular structure at the macroscopic scale, through ordered assemblies of the fibril matrix structure and cell walls at the nanoscopic scale, right down to the cellulose which forms the (partially) crystalline building blocks at the macromolecular level. “ForMAX will improve our understanding of the complex structure-function relationship in forest-based materials and food products across multiple length scales,” Kim Nygård, ForMAX beamline manager, told Treesearch Insight.

ForMAX is a flexible instrument that enables the study of materials in situ during processing and under realistic conditions

Kim Nygård, ForMAX beamline manager

A notable feature of ForMAX is the beamline’s multimodal imaging capability, combining full-field microtomography and SWAXS sequentially in the same experiment. “Fast, efficient switching between set-ups allows collection of imaging and scattering data on the same sample,” noted Nygård. In other words: full-field microtomography to provide the user with an overview of 3D structure and regions of interest, with localized SWAXS then used to investigate structure and orientation at the nanoscopic level (see also “Versatile by design: the ForMAX experimental station”, below).

“ForMAX is a flexible scientific instrument that also provides the temporal resolution to study materials in situ during processing and under realistic conditions such as applied temperature or pressure,” added Nygård. A unique feature is the beamline’s RheoSWAXS capability, integrating a state-of-the-art rheometer (supplied by Anton Paar, an Austrian metrology company) with polarized-light imaging and SWAXS to study orientational dynamics of wood-based samples across a range of length scales and under steady and oscillating shear conditions. Since shear-aligned cellulose nanocrystals exhibit structural colour, such studies could, for example, pave the way for the use of printed cellulose suspensions instead of traditional inks in future biobased packaging.

Getting ready to shine

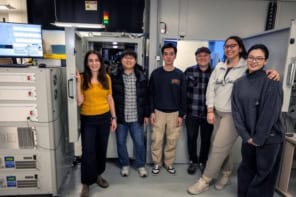

Although ForMAX has only been up and running for little more than six months, early-adopting Treesearch partners are already showing the way with their initial experimental runs. A case in point is an industry-academia collaboration on fibre-based sustainable food packaging involving Swedish packaging giant Tetra Pak and researchers at Chalmers University of Technology in Gothenburg.

Using ForMAX’s SWAXS imaging techniques, Linnéa Björn of Chalmers and Eskil Andreasson of Tetra Pak told Treesearch Insight attendees how the joint team – working closely with ForMAX staff scientists – is studying the nanostructure of fibre-based materials in an effort to optimize the composition and volume manufacture of paper straws.

If that seems like a narrow focus, the wider commercial imperative is clear: while there is growing market demand for more sustainable alternatives to plastic packaging, manufacturers like Tetra Pak must ensure that paper-based materials will remain food-safe, recyclable and durable against liquids and humidity. Put simply, the task for the Chalmers–Tetra Pak team is to understand the correlation between wetting of the paper straw with different liquids (water and orange juice, for example) as well as the impact of process treatments on the nanoscale structure.

“Our first experiment at ForMAX provided analysis into how paper-straw material responds to changes in the environment in real-time, as well as how the straw interacts with different types of liquids under stringent conditions,” explained Andreasson, a technology specialist in virtual modelling at Tetra Pak. “These insights will be applied to develop the paper straws of the future in our computer modelling tools, helping us to improve their functionality.” Further Tetra Pak collaborations are already in the works at ForMAX, including the use of real-time 4D X-ray microtomography to study water transport mechanisms in sustainable paper straws.

We can exploit synchrotron technology to optimize our manufacturing processes or enhance the fundamental understanding of our products and their performance

Christophe Barbier, senior research manager, Billerud

The application of synchrotron X-rays in product development was reinforced by Christophe Barbier, a senior research manager in paper physics with Billerud, the Swedish pulp and paper manufacturer which also specializes in fibre-based packaging materials for food, drink and medical applications. “We can exploit synchrotron technology in several ways,” he explained at Treesearch Insight. “To optimize our manufacturing processes, for example, or enhance the fundamental understanding of our products and their physical performance, as well as to drive product superiority and competitive differentiation.”

Barbier and his colleagues are long-time converts to “big science” who have seen the benefits of synchrotron light sources up close. Previously, the team has booked beam time at DESY’s PETRA III facility in Hamburg, Germany, to study the fundamentals of mechano-sorptive creep (an effect that can see stacked cardboard boxes of fresh produce, for example, unexpectedly buckle due to tensile load when ambient warehouse temperature or humidity exceed certain limits).

“We set out to establish that synchrotron-based X-ray scattering techniques can detect the effects of mechano-sorptive creep on the ultrastructure of pulp fibres,” noted Barbier. “The results are sufficiently encouraging to warrant continued SWAXS investigations of the phenomenon and, we hope, to eventually develop appropriate countermeasures.”

Proximity being what it is, Billerud is also gearing up for further studies at MAX IV’s ForMAX beamline. Current lines of enquiry, in collaboration with the 4D Imaging Lab at Lund University, include the use of X-ray microtomography to characterize “multi-ply” packaging (comprising multilayer or composite materials) and correlate its microscale properties versus bulk performance under load in forming machines.

“Treesearch is our door-opener to large-scale research facilities like MAX IV,” Barbier concluded. “There is huge potential for such facilities to address knowledge gaps in many areas relating to forest materials and sustainable products.”

- For further information, readers can access the Treesearch Insight poster abstracts online, including research studies on bio-based smart materials for water treatment; a portable Raspberry Pi-based light tomography scanner for educational and scientific use; and synchrotron techniques as a tool to investigate the wood-pulping process.

Versatile by design: the ForMAX experimental station

To maximize flexibility for visiting scientists, the ForMAX end-station is built around a single experimental table, with tomography microscope/cameras and SWAXS detectors added in a modular manner. This arrangement ensures efficient switching between different modes of operation, allowing combined full-field tomography and SWAXS experiments in a sequential manner.

In this way, the in-house design of the experimental station is tailored to the specific needs of ForMAX’s user community. Key building blocks include:

- Two beam-conditioning units, including slits, beam diagnostics equipment and two sets of secondary optics to achieve a large range of beam spot size at the sample position (from up to approx. 5 mm field-of-view in tomographic imaging down to approx. 1 micron real-space resolution in scanning SWAXS experiments).

- An experimental table with 200 mm vertical and horizontal (transverse) translation ranges and 200 kg load capacity.

- A motorized detector gantry so that the user can move the WAXS detector and tomography microscope in and out of the X-ray beam path (i.e. allowing combined full-field microtomography and SWAXS experiments in sequential mode).

- A 9 m long, evacuated SAXS flight tube with SAXS detector inside on a motorized XYZ trolley; sample-to-detector distance can be varied between approximately 1.2 and 7.5 m.