A superhydrophobic thin film that can be coated onto virtually any substrate has been synthesized by an international team of researchers. The material, produced using a 3D nanotextured hydrogel matrix, is strong, very flexible and optically transparent. It might be used as a waterproof coating in applications such as self-cleaning windows, antifouling surfaces, and as a filter and sponge to separate oil from water after an industrial oil spill.

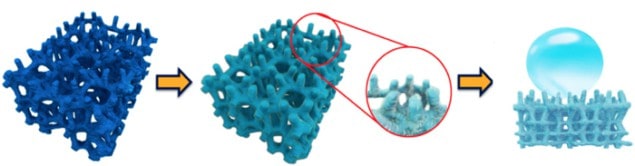

Superhydrophobic surfaces efficiently repel water in a phenomenon that is also known as the “lotus effect”. Now, a team led by Guihua Yu and Yi Shi from Nanjing University in China, along with colleagues at the University of Texas at Austin in the US, has made a new type of superhydrophobic surface comprising a 3D silica nanostructure replicated from a hydrogel template. The resulting hybrid coating consists of 3D interconnected nanofibres with uniform diameters of about 100 nm. Its morphology is like that of the lower surface of a lotus leaf, which contains micron-sized bumps that, in turn, are covered with nanoscale hair-like tubes. The nanofibres trap air under any water drops falling on them, creating a surface that repels water.

Stretched to their limit

The films produced by these inherently 3D nanotextured hydrogel templates remain superhydrophobic, even when stretched to their limit – and after more than 5000 stretching cycles at 100% strain. This is a first, because most superhydrophobic surfaces made to date lose their hydrophobic properties when exposed to a strain of more than 30%.

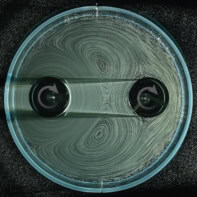

The films can be coated onto virtually any substrate, including metals, cement, wood, fabrics and plastics, thanks to their good wettability. They are also optically transparent (letting through 98% of light falling on them). They might come in handy as screen filters and sponges for separating oil from water, says Yu, because they can absorb up to 40 times their weight in oil.

The researchers made their superhydrophobic films using a polyaniline (PAni) hydrogel template. First, they mixed three precursor solutions together: an aqueous solution of oxidative initiator; an aqueous solution of aniline monomer and phytic acid; and tetraethoxysilane in isopropanol. The polyaniline hydrogel polymerizes and gels out fairly fast, and forms a 3D structure within three minutes.

Thanks to the high-acidic, high-water-content hydrogel matrix, the silica layer preferentially coats onto the PAni nanostructured template. Next, the silica layer is chemically modified, or “silanized” by depositing trichloro(octadecyl)silane onto the template to produce a superhydrophobic surface. The overall process is simple and can be scaled up to produce large amounts of superhydrophobic film, team member Lijia Pan told physicsworld.com.

The Texas–Nanjing researchers say that they are now looking at making super-oleophobic (oil-repelling) surfaces using the same hydrogel matrix template but a different version of their process.

The research is published in Nano Letters.

- This article first appeared on nanotechweb.org