Researchers have fabricated a room-temperature thermoelectric material that is as good as the best commercially available material in its class but is much cheaper. The material, which is based on n-type Mg3Bi2, could be used in solid-state cooling applications.

Thermoelectric materials make use of the flow of heat from a cooler area to a warmer one and have a large Peltier effect, which describes how heat transfers between two electrical junctions. Bismuth telluride alloys are the best room-temperature thermoelectric materials known today but they are costly because of the large amounts of expensive tellurium they contain.

A team of researchers led by Zhifeng Ren of the University of Houston and Gang Chen of the Massachusetts Institute of Technology have now made new thermoelectric materials based on an electron-doped magnesium-bismuth alloy. These have a thermoelectric figure-of-merit, ZT (which defines how efficiently a thermoelectric material works) of around 0.9 at 350 K, which is comparable to that of the commercial Bi2Te3-xSex.

The new material is much cheaper than Bi2Te3-xSex though, explains study lead author Jun Mao. “Although the high cost of this material has recently dropped, it remains about $50/kg. That compares to about just $6/kg for magnesium, which is a primary component of our new material.”

Delta T of more than 90 K

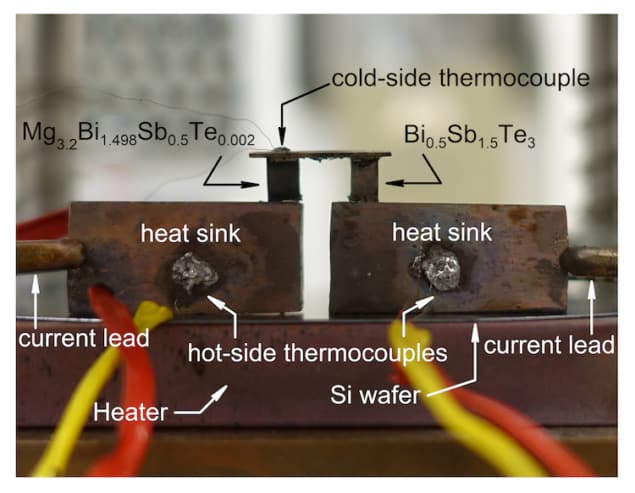

The researchers made a cooling device from their material (n- type Mg3.2Bi1.498Sb0.5Te0.002) and p-type Bi0.5Sb1.5Te3 and measured how efficiently it can cool the surface of a copper plate.

“The Peltier effect allows us to remove heat from the top, cold side of the copper plate and dissipate it into the bottom, hot side when we apply an electric current to the device,” says Mao. “This results in a temperature difference (delta T) between the two sides that increases with increasing current until it eventually saturates at 91 K while we maintain the hot side temperature at 350 K.”

And that is not all. The Houston-MIT team also found that the material is much easier to contact electrically (with metals like iron or nickel for example) in a simple one-step process than nanostructured Bi2Te3-xSex.

Topological semimetals go thermoelectric

“The new material can be used for both cooling and generating power, but we have only reported on its cooling performance in this work,” Mao tells Physics World. “We are now focusing on improving its ZT further and its cooling delta temperature.”

The researchers, reporting their work in Science 10.1126/science.aax7792, say they will also look at using the material for power generation up to 400°C.