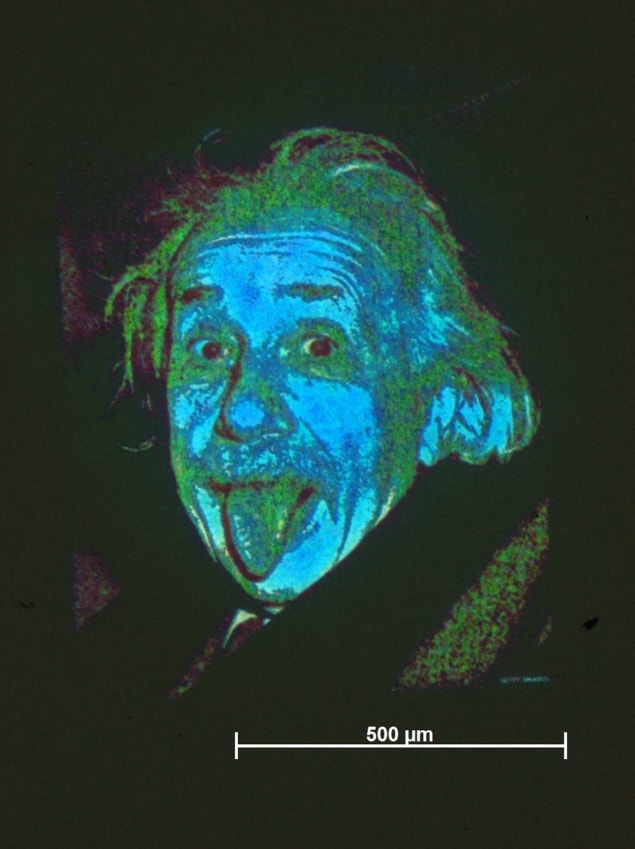

Controlled stress in polymers, including polystyrene, polycarbonate and polysulfone, can cause a change in visible-light reflection that results in inkless colouring, report researchers from the University of Kyoto, led by Easan Sivaniah in their recent Nature paper. They describe how they used the technique to produce high-resolution ‘structurally coloured’ polymers, without ink.

The researchers suggest multiple uses for this technology, including banknotes and rapid 3D-printing (using ink to colour 3D printing polymers is a rate-limiting step), food and medicine packaging, production of porous networks for gases and liquids, and use in wearable devices.

Controlled Crazing

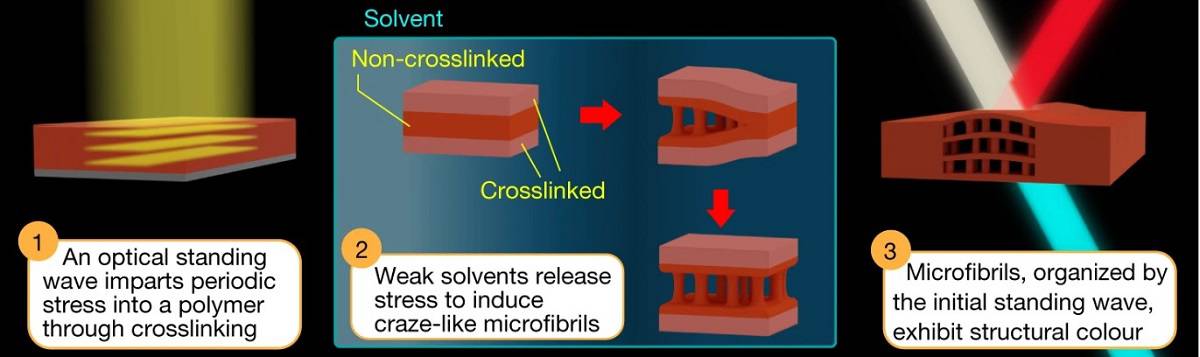

Molecular stress of polymers can lead to the formation of micropores and microfibrils within their structures. This phenomenon, called crazing, can cause material failure, but, if used in a controlled manner, it can tune the polymer’s colour.

The interaction of standing-waves with polymers naturally produces cross-links (bonds between polymeric chains) in alternate layers, which causes stress in the non-crosslinked ones. In addition when a polymer interacts with non-dissolving solvents, it can relieve the stress and form crazes. The presence of these layered structures modifies the refractive index of the material and its light scattering properties.

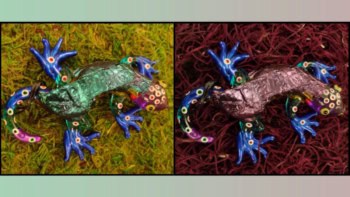

Sivaniah and his team use this combination of standing-wave cross-link formation and non-dissolving solvents – to modify the polymer’s colour. The process – defined as organized stress microfibrillation – can lead to controlled and tunable crazing. By protecting the dark areas of the image from the standing wave and avoiding the formation of crosslinks they showed they could obtain patterns and images.

Technique improving

In principle, this method generates all the colours of the visible spectrum, by varying the craze structures and patterns. However, not every colour has been obtained so far. Exploring different conditions such as temperature, solvents and material may help to refine this technique, increasing its impact on applications of ink-free colour.