It can be hard to pin down exactly what materials science is all about. But Honor Powrie believes the field is the most rewarding and challenging in all of science, with its practitioners striving to create “new gold”

For many years, I’ve been a judge for awards and prizes linked to research and innovation in engineering and physics. It’s often said that it’s better to give than to receive, and it’s certainly true in this case. But another highlight of my involvement with awards is learning about cutting-edge innovations I either hadn’t heard of or didn’t know much about.

One area that never fails to fascinate me is the development of new and advanced materials. I’m not a materials scientist – my expertise lies in creating monitoring systems for engineering – so I apologize for any over-simplification in what follows. But I do want to give you a sense of just how impressive, challenging and rewarding the field of materials science is.

It’s all too easy to take advanced materials for granted. We are in constant contact with them in everyday life, whether it’s through applications in healthcare, electronics and computing or energy, transport, construction and process engineering. But what are the most important materials innovations right now – and what kinds of novel materials can we expect in future?

Drivers of innovation

There are several – and all equally important – drivers when it comes to materials development. One is the desire to improve the performance of products we’re already familiar with. A second is the need to develop more sustainable materials, whether that means replacing less environmentally friendly solutions or enabling new technology. Third, there’s the drive for novel developments, which is where some of the most ground-breaking work is occurring.

On the environmental front, we know that there are many products with components that could, in principle, be recycled. However, the reality is that many products end up in landfill because of how they’ve been constructed. I was recently reminded of this conundrum when I heard a research presentation about the difficulties of recycling solar panels.

Photovoltaic cells become increasingly inefficient with time and most solar panels aren’t expected to last more than about 30 years. Trouble is, solar panels are so robustly built that recycling them requires specialized equipment and processes. More often than not, solar panels just get thrown away despite mostly containing reusable materials such as glass, plastic and metals – including aluminium and silver.

It seems ironic that solar panels, which enable sustainable living, could also contribute significantly to landfill. In fact, the problem could escalate significantly if left unaddressed. There are already an estimated 1.8 million solar panels in use the UK, and potentially billions around the world, with a rapidly increasing install base. Making solar panels more sustainable is surely a grand challenge in materials science.

Waste not, want not

Another vital issue concerns our addiction to new tech, which means we rarely hang on to objects until the end of their life; I mean, who hasn’t been tempted by a shiny new smartphone even though the old one is perfectly adequate? That urge for new objects means we need more materials and designs that can be readily re-used or recycled, thereby reducing waste and resource depletion.

As someone who works in the aerospace industry, I know first-hand how companies are trying to make planes more fuel efficient by developing composite materials that are stronger and can survive higher temperatures and pressures – for example carbon fibre and composite matrix ceramics. The industry also uses “additive manufacturing” to enable more intricate component design with less resultant waste.

Plastics are another key area of development. Many products are made from single type, recyclable materials, such as polyethylene or polypropylene, which benefit from being light, durable and capable of withstanding chemicals and heat. Trouble is, while polyethene and polypropene can be recycled, they both create the tiny “microplastics” that, as we know all too well, are not good news for the environment.

Bio-based materials are becoming more common for everyday items. Think about polylactic acid (PLA), which is a plant-based polymer derived from renewable resources such as cornstarch or sugar cane. Typically used for food or medical packaging, it’s usually said to be “compostable”, although this is a term we need to view with caution.

Sadly, PLA does not degrade readily in natural environments or landfill. To break it down, you need high-temperature, high-moisture industrial composting facilities. So whilst PLAs come from natural plants, they are not straightforward to recycle, which is why single-use disposable items, such as plastic cutlery, drinking straws and plates, are no longer permitted to be made from it.

Thankfully, we’re also seeing greater use of more sustainable, natural fibre composites, such as flax, hemp and bamboo (have you tried bamboo socks or cutlery?). All of which brings me to an interesting urban myth, which is that in 1941 legendary US car manufacturer Henry Ford built a car apparently made entirely of a plant-based plastic – dubbed the “soybean” car (see box).

The soybean car: fact or fiction?

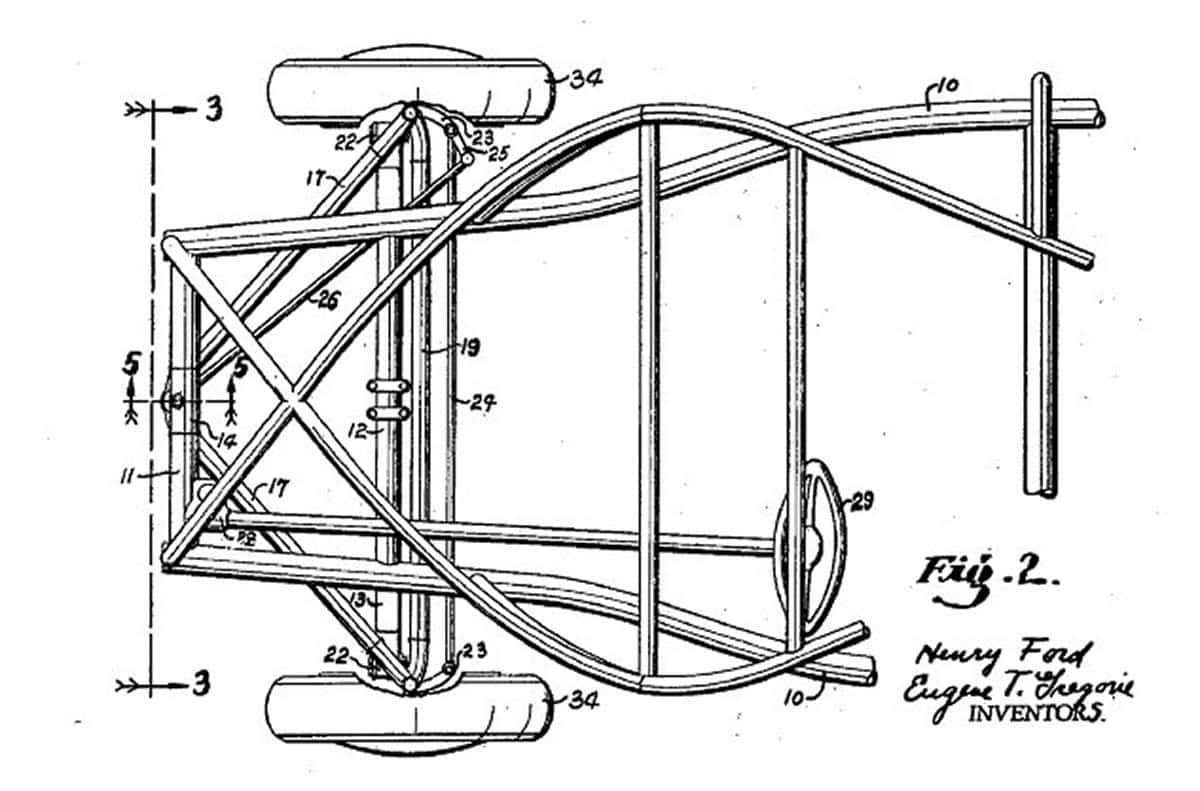

Henry Ford’s 1941 “soybean” car, which was built entirely of a plant-based plastic, was apparently motivated by a need to make vehicles lighter (and therefore more fuel efficient), less reliant on steel (which was in high demand during the Second World War) and safer too. The exact ingredients of the plastic are, however, not known since there were no records kept.

Speculation is that it was a combination of soybeans, wheat, hemp, flax and ramie (a kind of flowering nettle). Lowell Overly, a Ford designer who had major involvement in creating the car, said it was “soybean fibre in a phenolic resin with formaldehyde used in the impregnation”. Despite being a mix of natural and synthetic materials – and not entirely made of soybeans – the car was nonetheless a significant advancement for the automotive industry more than eight decades ago.

Avoiding the “solar-panel trap”

So what technology developments do we need to take materials to the next level? The key will be to avoid what I coin the “solar-panel trap” and find materials that are sustainable from cradle to grave. We have to create an environmentally sustainable economic system that’s based on the reuse and regeneration of materials or products – what some dub the “circular economy”.

Sustainable composites will be essential. We’ll need composites that can be easily separated, such as adhesives that dissolve in water or a specific solvent, so that we can cleanly, quickly and cheaply recover valuable materials from complex products. We’ll also need recycled composites, using recycled carbon fibre, or plastic combined with bio-based resins made from renewable sources like plant-based oils, starches and agricultural waste (rather than fossil fuels).

Vital too will be eco-friendly composites that combine sustainable composite materials (such as natural fibres) with bio-based resins. In principle, these could be used to replace traditional composite materials and to reduce waste and environmental impact.

Another important trend is developing novel metals and complex alloys. As well as enhancing traditional applications, these are addressing future requirements for what may become commonplace applications, such as wide-scale hydrogen manufacture, transportation and distribution.

Soft and stretchy

Then there are “soft composites”. These are advanced, often biocompatible materials that combine softer, rubbery polymers with reinforcing fibres or nanoparticles to create flexible, durable and functional materials that can be used for soft robotics, medical implants, prosthetics and wearable sensors. These materials can be engineered for properties like stretchability, self-healing, magnetic actuation and tissue integration, enabling innovative and patient-friendly healthcare solutions.

And have you heard of e-textiles, which integrate electronic components into everyday fabrics? These materials could be game-changing for healthcare applications by offering wearable, non-invasive monitoring of physiological information such as heart rate and respiration.

Further applications could include advanced personal protective equipment (PPE), smart bandages and garments for long-term rehabilitation and remote patient care. Smart textiles could revolutionize medical diagnostics, therapy delivery and treatment by providing personalized digital healthcare solutions.

Towards “new gold”

I realize I have only scratched the surface of materials science – an amazing cauldron of ideas where physics, chemistry and engineering work hand in hand to deliver groundbreaking solutions. It’s a hugely and truly important discipline. With far greater success than the original alchemists, materials scientists are adept at creating the “new gold”.

Their discoveries and inventions are making major contributions to our planet’s sustainable economy from the design, deployment and decommission of everyday items, as well as finding novel solutions that will positively impact way we live today. Surely it’s an area we should celebrate and, as physicists, become more closely involved in.