Alaina G Levine talks to Charles McCombie, an independent consultant on developing safe and secure nuclear waste disposal facilities, about his career and the latest thinking in nuclear waste science and technology

How did you get interested in nuclear waste management?

When I finished my doctorate in materials science and physics at the University of Bristol, UK, I deliberately wanted to move into a more socially involved field, and – I’m smiling here – I was a convinced environmentalist (and I still think I am). So I chose to go into nuclear energy after graduating. I worked for eight years on the reactors that young engineering students today still think of as “future generations”, such as high-temperature reactors, liquid metal-cooled fast reactors, gas-cooled fast reactors and pebble-bed reactors. This was the 1970s, a time when there was increasing opposition to nuclear energy, and I observed that part of the opposition stemmed from perceived issues in the radioactive waste management area. So I decided to move out of “front-end” reactor physics, because my perception was that the “back end”, the waste management, was being neglected and that this was costing a lot of public support for nuclear energy.

What did you do in your first job on the nuclear-waste side?

My reactor days were spent with national research institutions in the UK and Switzerland, and my first job in the “back end” was at the Swiss National Cooperative for the Disposal of Radioactive Waste (Nagra). I started as a safety assessment expert, because I knew about computer programming and there’s a lot of computer modelling involved in assessing the performance of nuclear repositories. After a while, I became the scientific and technical director, and that was exciting because I think of myself as a generalist, and the radioactive waste management field is incredibly interdisciplinary. By the end of my time at Nagra, I had been working with civil engineers, materials scientists, geophysicists, hydrogeologists and seismologists. I was also involved in public communication.

How much of your work now is scientific research and technical problem-solving, versus communication and policy?

With time I have come to agree that the biggest challenges in radioactive waste management are more social than technical and scientific. We have disposal technologies that we are convinced will be safe forever, but we don’t have enough confidence among the public and politicians to be able to implement these technologies. Radioactive materials produced in a nuclear reactor are very hazardous and, more importantly, they are hazardous for a very, very long time. So you have some materials you want to isolate from any potential human contact for 100,000 years or more. People had never thought in these timescales before, and the scientific community has only recently started to think about the consequences of technologies extending to these timescales. The good news is that we have very little of this material: a major nuclear power plant produces 1000 MW of electricity (generating revenues of more than $1m a day) and in a year it will produce only 20 tonnes of waste material. Furthermore, although 100,000 years is long on human timescales, it’s easy to find geologic formations that look the same today as they looked 100 million years ago. This presents a totally different time perspective.

How are waste materials stored?

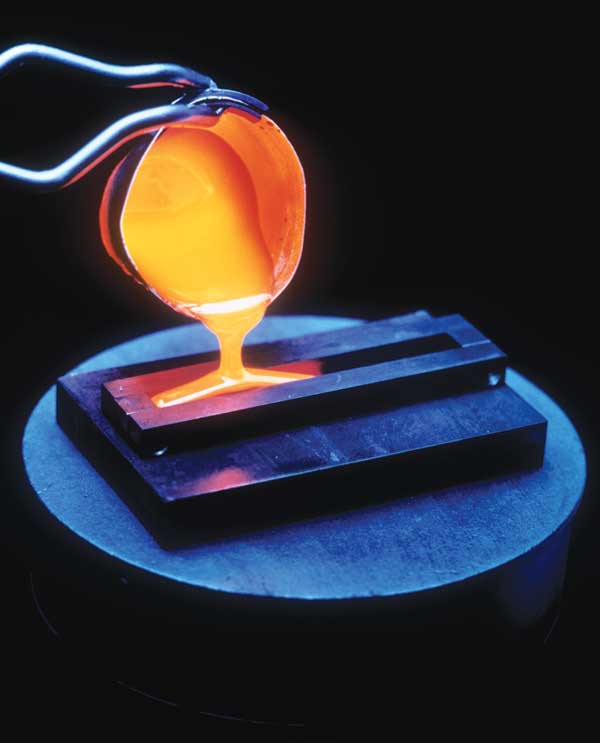

First, you don’t put the waste in any soluble or liquid form down in a geological repository. You make a solid waste matrix that is extremely resistant to any kind of corrosion or dissolution. The spent fuel is in the form of small ceramic pellets, and these have been in the reactor at hundreds of degrees for several years. They are very tough. You can dispose of these directly or else reprocess them to extract the radioactive nuclides, which are then mixed in a melter with glass so that you end up with these cylinders of black glass with the radioactive materials embedded in them. According to the best predictions that scientists can make, this glass takes more than 10,000 years to dissolve. You encase this glass in a stainless-steel sheath and put it in a copper container. Underground, where there is very little oxygen, copper acts like a noble metal, so these containers can last for more than 10,000 years. But you don’t stop there. The container goes into the repository at a depth of some hundreds of metres in a hard rock like a granite, a clay or salt. There it is surrounded by another barrier, which is often a special water-tight material called bentonite clay, that separates it from the host rock. So there’s a rock layer, a clay layer, a metal canister and inside that we have the waste matrix.

Where can nuclear waste management technology improve?

The most physics-oriented option is transmutation. If you irradiate long-lived radionuclides you can break them down into shorter-lived radionuclides. Many people would like to see a system where the radionuclide mix that comes out of a nuclear reactor would be treated. So you would separate it out into all its components. The useful ones, such as the much-maligned plutonium, can go straight into a reactor as fuel, but all of the other ones, almost without exception, can be transmuted if you strongly irradiate them. You can do this in a reactor, but it’s not easy in the light-water reactors that are prevalent today. Various organizations, including the Bill & Melinda Gates Foundation, are supporting other reactor types, such as fast reactors and small modular reactors, which can transmute much more of the waste than is currently done. You can also transmute them in a particle accelerator. Transmutation – either reactor driven or accelerator driven – is often pointed to as something that would change the face of radioactive waste management in the far future.

How far away are we from this?

Scientifically, no distance. But to upscale the technology so that it can be done economically and safely is quite far off, if it ever happens. It would costs loads of money and any further manipulation or treatment that you do of these highly radioactive materials would mean that process workers would be exposed to some level of radiation. Then you have an ethical question: how much extra radiation should I be prepared to give a process worker today to save tiny potential radiation doses to people thousands of years in the future?

The other challenge that bothers me is in the remediation and cleanup area. When sites get radioactively contaminated, you can have large areas that will never be safe for people to live on unless you do something clever. There are lots of interesting technologies – hydrological, geochemical and physical – being tried to clean up contaminated sites or sites where there have been accidents. The most recent striking example is at Fukushima in Japan, which following the 2011 earthquake, tsunami and reactor accident will be a mess for decades to come. It’s difficult to clean up a reactor if you don’t know what’s inside it, and it’s difficult to approach them because there’s molten fuel in there. One recent development that I think is really smart is to use muon technology as a remote sensing tool: if you can measure the flux of muons, you can use them like an X-ray to see an image of the melted fuel (corium), and try to get a sense of the scale of the problem.

What’s next for you?

I have been involved for many years in promoting the concept that not every country has to implement its own geological repository. We normally use two words when discussing waste disposal challenges: “safe”, meaning radiological and environmental safety, and “secure”, meaning safety against the deliberate misuse of the material. Despite setbacks, nuclear power is expanding globally. If you think of a potential future where instead of having 10–11 technologically advanced countries with advanced nuclear programmes you instead have 30–40 newcomer countries, each with one or two nuclear power plants, then this hazardous material will be sitting around the world in many locations. One of the ways to keep that material safer and more secure is to concentrate it in fewer, very well completed facilities. A large part of my life is devoted to developing this concept of multinational disposal.