A filament of liquid squirted from a nozzle will sometimes contract into a single drop and other times break up into many segments. Now, researchers in the UK have mapped the parameters that will lead a filament to break up, and they believe that this knowledge could help in the design of inkjet printers.

Inkjet printing requires single drops of ink to be deposited on paper, and for this reason engineers are keen to avoid conditions that would encourage ink filaments squirted from an inkjet nozzle to break up. Theory shows that there are several crucial parameters: the liquid’s density, viscosity and surface tension – all three of which can be grouped into a single “Ohnesorge number”. The other is the aspect ratio, which describes the filaments’ length in relation to diameter. In general, longer filaments with a high aspect ratio, and filaments with a small Ohnesorge number, are likely to break up.

However, experiments attempting to confirm this theory have been limited, according to Ian Hutchings and others at the University of Cambridge. To map break-up parameters, engineers have previously used commercially available printing nozzles, but these work only within a narrow range of liquid viscosities and at one filament diameter. “You can’t map anything – or you can map in a very small region,” says Alfonso Castrejón-Pita, a co-author of the latest study. “So [inkjet] companies have had to use trial and error.”

Specialized nozzle

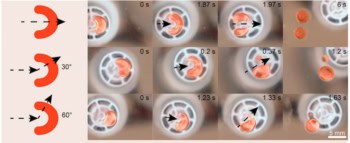

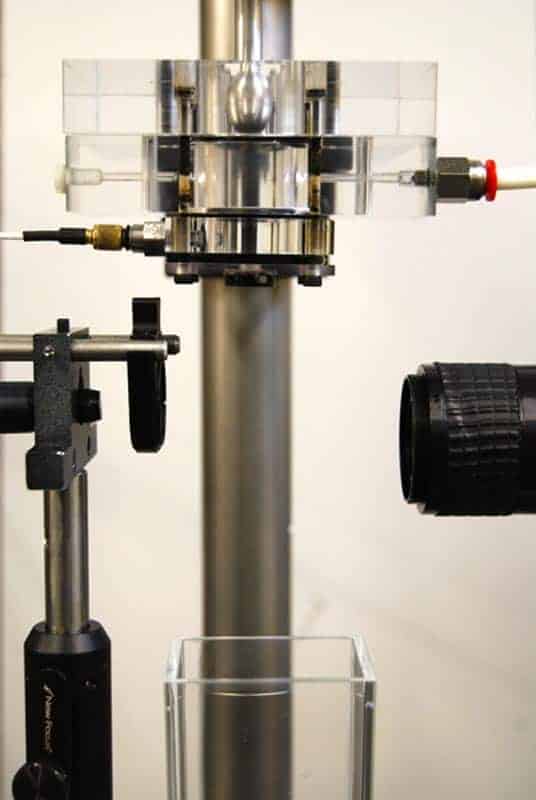

The Cambridge researchers have therefore developed their own nozzle. It is larger than a typical inkjet nozzle, and has an iris – similar to the aperture blades on a camera – that can control the diameter of the squirted fluid. What is more, the squirting mechanism relies on a speaker-like electromagnetic coil, which can handle even very viscous fluids. To detect break-up, the researchers photographed the ejected filaments using a high-speed camera.

They found that for short filaments with an aspect ratio less than about six – that is, with a length no greater than six times the diameter – no break-up occurs. They also found that break-up did not happen for large Ohnesorge numbers, greater than one. The results broadly agree with previous theory, but contain data points that stretch into previously untested regions.

“It has always proved easier to carry out such studies on computer rather than in the laboratory,” says Osman Basaran, an engineer at Purdue University in Illinois, US, who has contributed to the theory of how liquid filaments break up. “Therefore, the new experiments furnish experimental observations that had been needed for nearly a decade, if not longer.”

Basaran adds that there are slight discrepancies between the Cambridge researchers’ results and the theory, and hopes that these will prompt further work. But not all theorists are impressed. Jens Eggers of the University of Bristol, UK, thinks that the experimental data offer no surprises, and disagrees with the researchers that there should never be break-up for Ohnesorge numbers greater than one. “I would bet almost anything that this is false,” he says. “In any case, there isn’t much evidence in the data to support the claim.”

Brian Derby, who researches inkjet printing at the University of Manchester, UK, is ambivalent about the value of the extra data points, which he says are too distant from the values used in real-world devices. “It’s easier to see what’s going on,” he says. “But you could argue that they’ve extended the range outside of practical interest.”

In fact, Castrejón-Pita says his group’s results may not be directly applicable to inkjet printing anyway because they used water–glycerol mixtures for their tests. Actual ink, he says, might exhibit so-called non-Newtonian properties, which would make it deviate from the trends that they have observed. But this is an avenue that his group can explore. “Now we’re going to work with real things, with a real commercial print head, to check how far our predictions can be followed,” he says.

The study is published in Physical Review Letters.