If you’ve ever struggled to shift a heavy piece of furniture, you have probably noticed that rotating the furniture while pushing it makes things easier. Researchers in Germany and Italy have now investigated this same phenomenon on the microscale and, in the process, identified the conditions that should allow microscopic objects to spin across a crystalline surface with a bare minimum of torque. This theoretical finding, which the team backed up with experiments on tiny magnetic spheres, could aid the development of micro- and nano-machines for applications in areas such as robotics and drug delivery.

To move an object – be it big or small – one must apply a force to overcome its static translational friction with the underlying surface. This is a basic principle of mechanics, yet the relationship between translational and rotational friction is complex, and it becomes even more so on tiny length scales where the contacting surfaces can involve as little as a few hundred atoms. In nanosized devices, translational friction is a particular problem because their high surface area-to-volume ratios means that their surfaces quickly wear out and may even spontaneously stick together as they come into contact.

Mimicking the contact area between two atomically flat surfaces

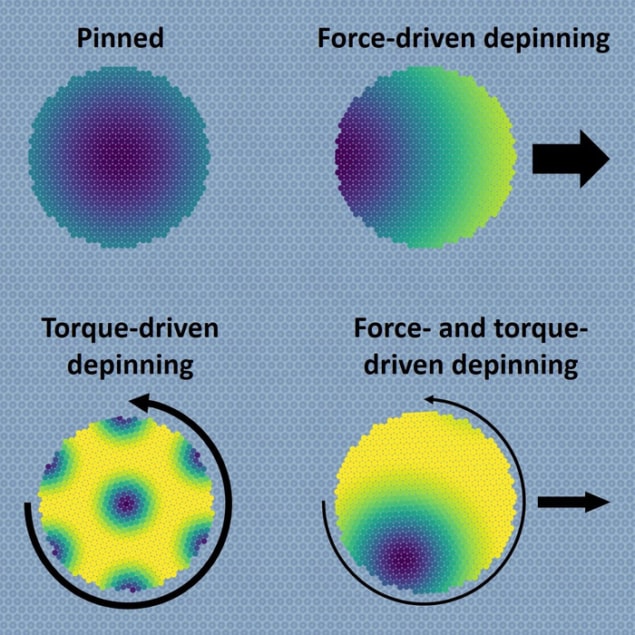

To study the relationship between static translational and rotational friction, members of a team led by Clemens Bechinger of the University of Konstanz, Germany began by making crystalline clusters of micron-sized magnetic spheres. They then brought these spheres into contact with a structured surface containing periodically-spaced wells like an egg carton. This set-up mimics the type of contact that occurs between two atomically flat surfaces, explains Xin Cao, a lead author of a paper on the research published in Physical Review X.

The researchers then rotated the clusters using a rotating magnetic field, keeping around 10 to 1000 spherical particles from each cluster in contact with the surface. The minimum torque required to make the cluster rotate corresponds to the static rotational friction, which the researchers explain is similar to the static translational friction that characterizes the minimum force required to push the cluster.

Friction does the heavy lifting in ropes and yarns

Once the rotation exceeds a certain threshold, the researchers found that static friction decreases dramatically, producing a state of ultralow static friction for very large clusters. “Such a low-friction state allows microscopic objects to be set in rotation by applying a minimal amount of torque and can be highly relevant for the fabrication and functioning of small mechanical devices – from the atomic to the micro-scale – bringing us closer to realizing smaller and more efficient machines,” Bechinger says.

A superposition of translation and rotation

“Under any realistic circumstances, the motion of objects are a superposition of translation and rotation,” he tells Physics World. “For many applications it is important to know the frictional resistance, which is accompanied with such motion because friction consumes energy and may even lead to the failure of devices. Unlike translational friction, little is known about rotational friction, but we have now addressed the latter in our study.”

So far, the researchers have focused on perfectly periodic surfaces. “In our future work, we will introduce defects, which are also present under many circumstances,” Bechinger says.