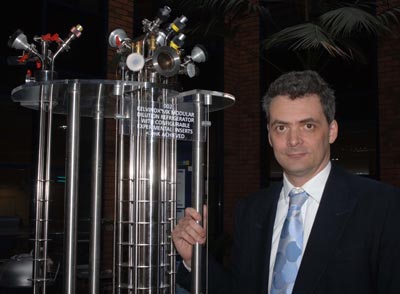

Physicist Jonathan Flint has been chief executive of Oxford Instruments since 2005 and has embarked on an aggressive plan to double the size of the business. He tells Hamish Johnston that this can only be done by seeking out and commercializing new ideas, many of which come from the physics research community and are channelled through an innovations process that he leads.

In many ways Oxford Instruments is the archetypal physics-based company. What relationship do you have with physicists today?

We have many strong ties with the physics community. We recruit heavily from universities and some of the best physics graduates come to work for us. We also have close links with leading universities such as Oxford, Cambridge and Imperial College, where we sponsor students, fund R&D and are involved in collaborative research programmes to push back the frontiers of science. When a breakthrough shows commercial potential, we will often work with researchers to commercialize it. Finally, many of our customers are physicists – either working in academia or industry.

Good relations with the physics community are crucial to our business model.

Good relations with the physics community are crucial to our business model. Most physicists first encounter our equipment when training in university labs. Some then get jobs in academia and need to buy equipment – and we are the first company that they think of. Others go on to be captains of industry and their organizations tend to buy our instruments because that is what they have spent their professional lives using.

How exactly do you plan to double the size of your business?

It would be very difficult to double the size of the business by simply selling more equipment to academics. We already have more than 50% of the market for much of the equipment we sell – and the demand for equipment in universities is not fast growing because government research grants tend to rise in line with a country’s gross domestic product. As a result we are moving more towards industrial markets, where we see greater opportunities for growth.

Is this where the company’s innovations process fits in?

We are constantly looking for bright ideas from both inside and outside the company that can be commercialized using the technological know-how of Oxford Instruments.

The innovations process provides a mechanism to sift through the ideas and find the ones with commercial potential. We focus on developing new ideas, commercializing them to make revenue, and then use that money to invest in the next idea. To do this, the company must be both innovative and profitable.

In your view what makes a good idea?

In addition to looking like it will deliver a financial return on our investment, an idea must fit into the areas that we have identified for growth – these are the technologies related to industrial processes, security, energy or the environment. In addition Oxford Instruments has to be able to contribute beyond just funding the idea – a venture capitalist could do that – so it has to be an area that we have expertise in. This could be our physics knowledge, our distribution network or our manufacturing skills.

What security-related projects are you working on?

One area that we believe has great commercial potential for Oxford Instruments is the development of terahertz detectors for use as security scanners in airports. Unlike current security systems, which are limited to detecting metal objects and sniffing out explosives, terahertz radiation could be very useful in detecting a wide range of materials, including explosives.

So far, terahertz systems have been under-utilized because the best detectors must be cooled to within a few degrees of absolute zero using liquid helium. This would be very difficult to implement in airports for health and safety reasons alone. However, deployment in airports would be possible if the terahertz detector were cooled with a cryogen-free system that does not need a constant supply of liquid helium but instead uses a small quantity of helium gas in a closed system.

Oxford Instruments already has expertise in terahertz detection and our interest in commercializing this technology was one reason why we bought VeriCold, the German manufacturer of cryogen-free cooling systems, earlier this year. Such systems will also be crucial in the development of quantum computers – another area that we have identified as having commercial potential.

There is a lot of work going on in physics labs to develop quantum computers. The most promising technologies for quantum computing must operate at very close to absolute zero and our equipment is becoming the de facto standard for research in this field.

How do you see quantum computers developing?

While the technology is still in its infancy, I believe that quantum computers will become a standard commodity product in years to come. As a physicist, I believe that quantum computers will definitely happen because there is so much funding going in to the research and the theoretical argument for it is just so overwhelming. The key breakthrough required could happen many years in the future or it could happen tomorrow. There are people who claim to have working quantum computers today. While their devices are not nearly as practical as conventional computers, I’m sure that we will get there.

While a practical quantum computer won’t be invented at Oxford Instruments, its development will be done using our tools. When quantum computers become commercially available, there will be a need for cryogenic cooling in a huge variety of locations – perhaps even in every home. That is a fantastic market for us – it’s where we have a very strong commercial lead.

As a major supplier of superconducting wire, you must see fusion reactors as a major opportunity in the energy sector?

Yes, the upcoming experimental fusion reactor ITER [International Thermonuclear Experimental Reactor] alone will increase world demand for superconducting wire by a third – and we are increasing our manufacturing capacity specifically for that reason by investing heavily in our wire factory in New Jersey, in the US.

At the moment, most wire is used for magnets in magnetic resonance imaging scanners and we are seeing a large growth in the market for this equipment in China.

What other energy-sector projects are you looking at?

High brightness LEDs [light-emitting diodes], which are currently being used mostly in the personal electronics and automotive sectors, are something that we see as having great potential. LEDs are very efficient compared with traditional light sources and could reduce the UK’s carbon footprint dramatically, overnight, if everyone used them in standard lighting applications. Unfortunately, at the moment LEDs are very expensive – £50 for a replacement bulb for the home – but we expect this price to come down as the technology matures.

The key to reducing the cost of these components is to improve the yield and throughput of the semiconductor process used to manufacture the LED devices – and we are continually improving our process tools to help manufacturers do just that.

How hard is it for your company to find the right kind of people to work on such a diverse range of projects?

There is absolutely not an adequate supply of such people. The most valuable employees are those who understand the underlying physics of a product to some degree and who can also communicate it effectively to a wider audience including our customers and shareholders – these are the people that really rise in the organization.

The problem is that the people with these broad skills don’t go into industry. They go into the City where short-term earnings can be higher.

What can Oxford Instruments offer such people?

We can give these people the thrill of inventing something. They get to turn a newly discovered physical phenomenon into an instrument that will be used by scientists to further our understanding of nature – our people get a fantastic buzz out of that.