Researchers at the Universidad Autónoma de Madrid in Spain have developed a new, simple, one-pot method to make highly conductive metal-organic ultrathin films that are both flexible and mechanically strong. The films can be produced over areas as large as mm2, are smooth, highly transparent and behave as memristors at low frequencies. They might be used in a wide variety of flexible electronics applications in the future, including health-monitoring devices.

“The future of 2D flexible electronics will rely on making conducting ultrathin films of materials that are mechanically robust and flexible in a simple but controlled manner,” says Miriam Moreno-Moreno, who is the lead author of this study. “In this respect, metal-organic compounds are better than inorganic laminar crystals. While most metal-organic compounds are usually prepared in the bulk, researchers have recently found that some can be processed down to ultrathin, 2D films. In our work, we report on a one-pot technique (carried out on the surface of water) to make ultrathin films (just 4 nm thick) of the metal organic compound [Cu2I2(TAA)]n where TAA is thioacetamide.”

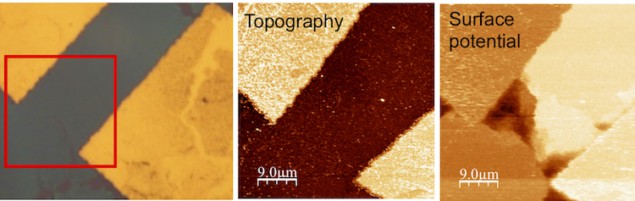

The films are homogenous over mm2 areas, are smooth and highly transparent. They are also mechanically strong, boasting a Young’s modulus of 11 GPa and a yield strength of 1 GPa. They have an electrical conductivity as high as 50 S/cm and behave as memristors at low frequencies, that is, they “remember” the amount of charge that has flowed through them, with this information being stored in their resistance.

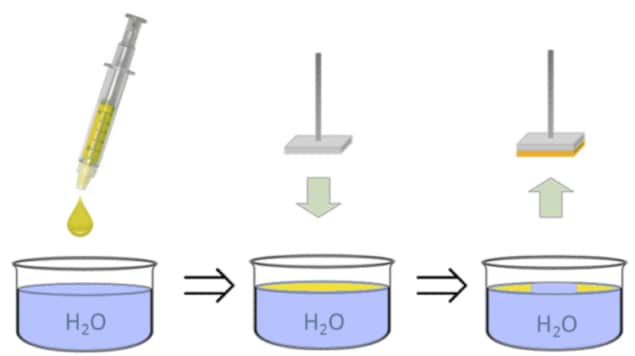

The researchers made their films by first preparing a solution containing the building blocks, CuI and thioacetamide, which are cheap and readily available materials. They then added a drop of this solution to ultrapure water in a Petri dish. “The films form immediately on the water surface and are clearly visible at the right light angle,” says Moreno-Moreno. “We then fish out these films and place them on a substrate by carefully bringing the substrate into contact with the water surface containing the film. Finally, we dry the substrate using a flow of argon or nitrogen gas.”

Moreno-Moreno reckons that the films might be used in a host of flexible and transparent electronics. “One example is in fitness wristbands for monitoring heart rate.”

The team, reporting its work in ACS Nano 10.1021/acsnano.8b05056, says that it is now busy trying to control how the grain boundaries in the films form and migrate. “These grain boundaries are responsible for the films’ electrical properties and controlling these will allow us to tune the electro-mechanical properties of devices based on this material,” Moreno-Moreno tells Physics World.