Roasting metal organic frameworks (MOFs) could make them more effective at capturing CO2 to remove a key greenhouse gas from the atmosphere, according to recent research by Kumar Varoon Agrawal and co-workers at the École Polytechnique Fédérale de Lausanne. Reporting in Advanced Materials, they show that heating a membrane of zeolitic imidazolate framework 8 (ZIF-8) to an optimum temperature of about 360°C for about 3 to 5 seconds – what they describe as rapid heat treatment (RHT) – could lead to more selective CO2 capture.

Metal organic frameworks (MOFs)

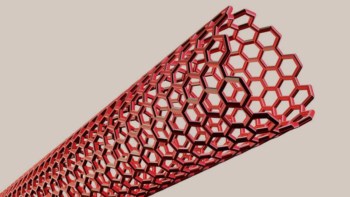

Polycrystalline MOFs are a class of compounds consisting of metal ions or clusters linked together by organic ligands to form one-, two-, or three-dimensional porous structures. They have applications in a wide range of fields ranging from catalysis, gas storage, biological sensing and imaging, and drug delivery stems, among others.

Due to their small, tunable pore sizes and high pore volumes, MOFs are promising materials for use as an adsorbent to capture CO2. However, their flexible lattice structures render them less suitable for selective adsorption or separation of gases with specific molecular sizes.

Rapid heat treatment (RHT)

For the RHT in their study, Agrawal and colleagues used a 5 inch quartz tube furnace, with a 1 inch quartz tube placed inside to purposefully ensure uniform temperature throughout the sample. They then placed the ZIF‐8 membrane in a custom‐built sample holder – using a thermocouple for accurate temperature measurements. To reach the desired temperature, they then set the furnace to 500 °C, and inserted the sample for 3-5s, before pulling it out, sealing with epoxy and performing their permeation measurements.

Whatever happened to carbon capture?

Unprecedented gas selectivity

Agrawal and colleagues report that the RHT of the synthesized polycrystalline ZIF‐8 membranes distorts the material lattice structure and reduces its flexibility, preventing larger molecules from permeating. To prove this, they showed that an obtained temperature-activated gas transport led to different interaction strengths between various guest-molecules and the membrane because the activation energy increases significantly with molecular size (CH4 > CO2 > H2). Consequently, the researchers were able to achieve unprecedented selectivity in the ratio of the separated gases H2/CH4, CO2/CH4 and CO2/N2 in excess of 175, 30 and 30, respectively. This far outweighs the current maximum selectivity obtained for CO2/CH4 and CO2/N2, which is 5.

The scientists report that by choosing the RHT conditions, the performance of MOFs could be tuned to the desired rigidity for selective adsorption and separations. They report, “In general, heat treatment to a higher temperature within an optimal window, a faster ramping rate, and higher treatment time (dwell time) led to a sharper molecular cut‐off”.