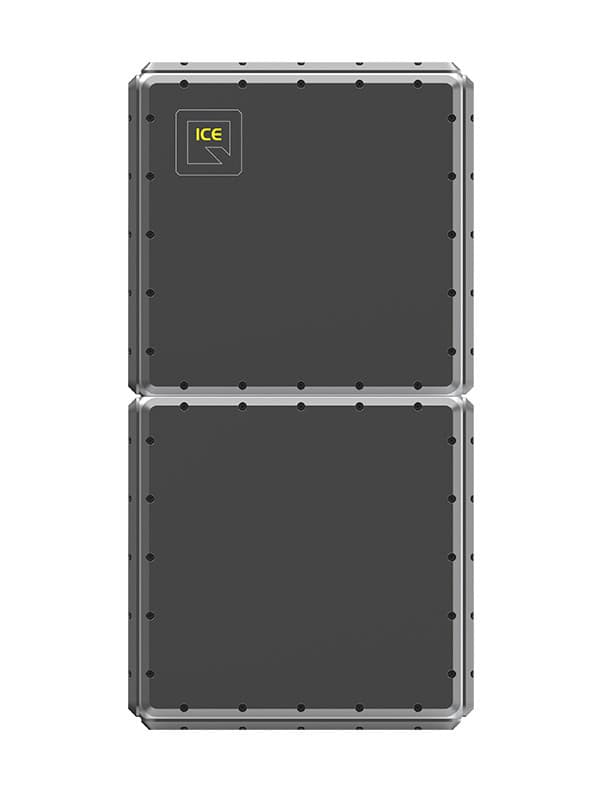

With a cube-based design that fits into a standard rack mount, the ICE-Q platform delivers the reliability and scalability needed to exploit quantum systems in real-world operating environments

At the centre of most quantum labs is a large cylindrical cryostat that keeps the delicate quantum hardware at ultralow temperatures. These cryogenic chambers have expanded to accommodate larger and more complex quantum systems, but the scientists and engineers at UK-based cryogenics specialist ICEoxford have taken a radical new approach to the challenge of scalability. They have split the traditional cryostat into a series of cube-shaped modules that slot into a standard 19-inch rack mount, creating an adaptable platform that can easily be deployed alongside conventional computing infrastructure.

“We wanted to create a robust, modular and scalable solution that enables different quantum technologies to be integrated into the cryostat,” says Greg Graf, the company’s engineering manager. “This approach offers much more flexibility, because it allows different modules to be used for different applications, while the system also delivers the efficiency and reliability that are needed for operational use.”

The standard configuration of the ICE-Q platform has three separate modules: a cryogenics unit that provides the cooling power, a large payload for housing the quantum chip or experiment, and a patent-pending wiring module that attaches to the side of the payload to provide the connections to the outside world. Up to four of these side-loading wiring modules can be bolted onto the payload at the same time, providing thousands of external connections while still fitting into a standard rack. For applications where space is not such an issue, the payload can be further extended to accommodate larger quantum assemblies and potentially tens of thousands of radio-frequency or fibre-optic connections.

The cube-shaped form factor provides much improved access to these external connections, whether for designing and configuring the system or for ongoing maintenance work. The outer shell of each module consists of panels that are easily removed, offering a simple mechanism for bolting modules together or stacking them on top of each other to provide a fully scalable solution that grows with the qubit count.

The flexible design also offers a more practical solution for servicing or upgrading an installed system, since individual modules can be simply swapped over as and when needed. “For quantum computers running in an operational environment it is really important to minimize the downtime,” says Emma Yeatman, senior design engineer at ICEoxford. “With this design we can easily remove one of the modules for servicing, and replace it with another one to keep the system running for longer. For critical infrastructure devices, it is possible to have built-in redundancy that ensures uninterrupted operation in the event of a failure.”

Other features have been integrated into the platform to make it simple to operate, including a new software system for controlling and monitoring the ultracold environment. “Most of our cryostats have been designed for researchers who really want to get involved and adapt the system to meet their needs,” adds Yeatman. “This platform offers more options for people who want an out-of-the-box solution and who don’t want to get hands on with the cryogenics.”

Such a bold design choice was enabled in part by a collaborative research project with Canadian company Photonic Inc, funded jointly by the UK and Canada, that was focused on developing an efficient and reliable cryogenics platform for practical quantum computing. That R&D funding helped to reduce the risk of developing an entirely new technology platform that addresses many of the challenges that ICEoxford and its customers had experienced with traditional cryostats. “Quantum technologies typically need a lot of wiring, and access had become a real issue,” says Yeatman. “We knew there was an opportunity to do better.”

However, converting a large cylindrical cryostat into a slimline and modular form factor demanded some clever engineering solutions. Perhaps the most obvious was creating a frame that allows the modules to be bolted together while still remaining leak tight. Traditional cryostats are welded together to ensure a leak-proof seal, but for greater flexibility the ICEoxford team developed an assembly technique based on mechanical bonding.

The side-loading wiring module also presented a design challenge. To squeeze more wires into the available space, the team developed a high-density connector for the coaxial cables to plug into. An additional cold-head was also integrated into the module to pre-cool the cables, reducing the overall heat load generated by such large numbers of connections entering the ultracold environment.

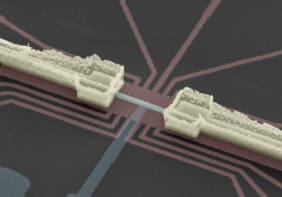

Meanwhile, the speed of the cooldown and the efficiency of operation have been optimized by designing a new type of heat exchanger that is fabricated using a 3D printing process. “When warm gas is returned into the system, a certain amount of cooling power is needed just to compress and liquefy that gas,” explains Kelly. “We designed the heat exchangers to exploit the returning cold gas much more efficiently, which enables us to pre-cool the warm gas and use less energy for the liquefaction.”

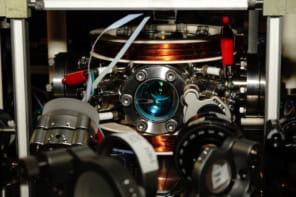

The initial prototype has been designed to operate at 1 K, which is ideal for the photonics-based quantum systems being developed by ICEoxford’s research partner. But the modular nature of the platform allows it to be adapted to diverse applications, with a second project now underway with the Rutherford Appleton Lab to develop a module that that will be used at the forefront of the global hunt for dark matter.

Already on the development roadmap are modules that can sustain temperatures as low as 10 mK – which is typically needed for superconducting quantum computing – and a 4 K option for trapped-ion systems. “We already have products for each of those applications, but our aim was to create a modular platform that can be extended and developed to address the changing needs of quantum developers,” says Kelly.

As these different options come onstream, the ICEoxford team believes that it will become easier and quicker to deliver high-performance cryogenic systems that are tailored to the needs of each customer. “It normally takes between six and twelve months to build a complex cryogenics system,” says Graf. “With this modular design we will be able to keep some of the components on the shelf, which would allow us to reduce the lead time by several months.”

More generally, the modular and scalable platform could be a game-changer for commercial organizations that want to exploit quantum computing in their day-to-day operations, as well as for researchers who are pushing the boundaries of cryogenics design with increasingly demanding specifications. “This system introduces new avenues for hardware development that were previously constrained by the existing cryogenics infrastructure,” says Kelly. “The ICE-Q platform directly addresses the need for colder base temperatures, larger sample spaces, higher cooling powers, and increased connectivity, and ensures our clients can continue their aggressive scaling efforts without being bottlenecked by their cooling environment.”

- You can find out more about the ICE-Q platform by contacting the ICEoxford team at iceoxford.com, or via email at sales@iceoxford.com. They will also be presenting the platform at the UK’s National Quantum Technologies Showcase in London on 7 November, with a further launch at the American Physical Society meeting in March 2026.