The first effective technique for growing a batch of single-walled carbon nanotubes (SWCNTs) that all have the same molecular structure has been developed by scientists in Switzerland. The new process involves using “seed molecules” on a platinum substrate to grow SWCNTs with the desired structure. The breakthrough could be extremely important to those developing electronic devices based on SWCNTs because nanotubes with different structures can have very different electronic properties.

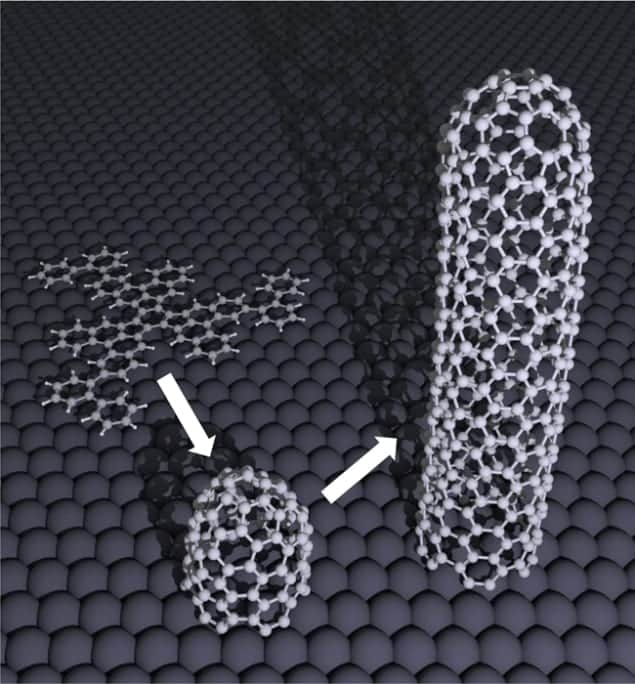

An SWCNT can be thought of as an atomically thin sheet of carbon that has been rolled up to form a tube about 1 nm thick, resembling a drinking straw. The carbon sheet always has the same honeycomb structure, which it shares with graphene. However, there are about a hundred different ways that the edges of the sheet can join together to make a tube, and this defines whether an SWCNT conducts electricity like a metal or a semiconductor. In the case of semiconducting nanotubes, the size of the electronic band gap also depends on how the edges are joined.

Electronic devices based on SWCNTs could, in principle, be used to create transistors and other components that are smaller, faster and more energy efficient than those based on silicon. But before that can happen, scientists have to come up with reliable ways of producing batches of SWCNTs with identical structures.

Costly separation

Careful control of how SWCNTs are prepared can limit the number of different structures to as few as five. Then SWCNTs with the desired structure can be separated from a mixture. However, this is a very costly process with a structurally pure sample of SWCNTs costing about $1000 per milligram from a chemical supplier. As a result, scientists are very keen on developing methods for producing batches containing just one structure.

This latest work was done by Juan Ramon Sanchez-Valencia and colleagues at the Swiss Federal Laboratories for Material Sciences and Technology (Empa) in Zürich.

The new technique is based on the fact that, unlike a drinking straw, the tips of SWCNTs are capped by carbon atoms and each species has a cap with a different structure. The team used the established technique of organic chemical synthesis to create cap molecules with the same structure as the cap of the desired structural species of SWCNT. These cap molecules are placed on a platinum surface, which is heated in the presence of a carbon-rich gas such as ethylene. The platinum surface acts as a catalyst, pulling carbon atoms from the gas and passing them to the cap molecules. This steady supply of carbon molecules attaches itself to the bottom of a cap and pushes it up from surface, creating an SWCNT with the desired structure.

Metallic armchairs

The cap molecules were designed to seed SWCNTs with the “(6,6) armchair” structure. This much-studied type of nanotube is of interest to device designers because it conducts electricity like a metal. The SWCNTs were grown to several hundred nanometres in length before they were analysed using scanning tunnelling microscopy (STM) and Raman spectroscopy. This revealed that the SWCNTS were all of the same type and were free of structural defects.

“The clever thing about this is that they predesign the cap and that cap then defines the nanotube type,” explains SWCNT expert James Tour at Rice University in the US, who was not involved in the research. Although the team did not show that the technique can create other types of SWCNTs by using different cap molecules, Tour says that this possibility “seems to be implied and it is likely that that would be the case”.

Making tonnes of nanotubes

An important benefit of the new technique is that 1 kg of seed molecules could, in principle, produce 5 tonnes of SWCNTs, each 10 μm in length. On the downside, a platinum surface measuring about 30 km2 would be needed to grow such a quantity of SWCNTs.

An additional challenge facing anyone wanting to use the technique to produce commercial quantities of SWCNTs is how to deal with the entanglement of neighbouring nanotubes. This occurs before the SWCNTs reach a usable length, and disentangling nanotubes can be a tricky process.

The new technique is described in Nature.