Analysis of human breath can provide a non-invasive method for cancer screening or disease diagnosis. The level of isoprene in exhaled breath, for example, provides a biomarker that can indicate the presence of lung cancer. Now a research collaboration from China and Spain has used nanoflakes of indium oxide (In2O3)-based materials to create a gas sensor with the highest performance of any isoprene sensor reported to date.

For effective cancer screening or diagnosis, a gas sensor must be sensitive enough to detect the small amounts of isoprene present in breath (in the parts-per-billion (ppb) range) and able to differentiate isoprene from other exhaled compounds. The metal oxide semiconductor In2O3 is a promising candidate for isoprene sensing, but existing devices are limited by high operating temperatures and low detection limits.

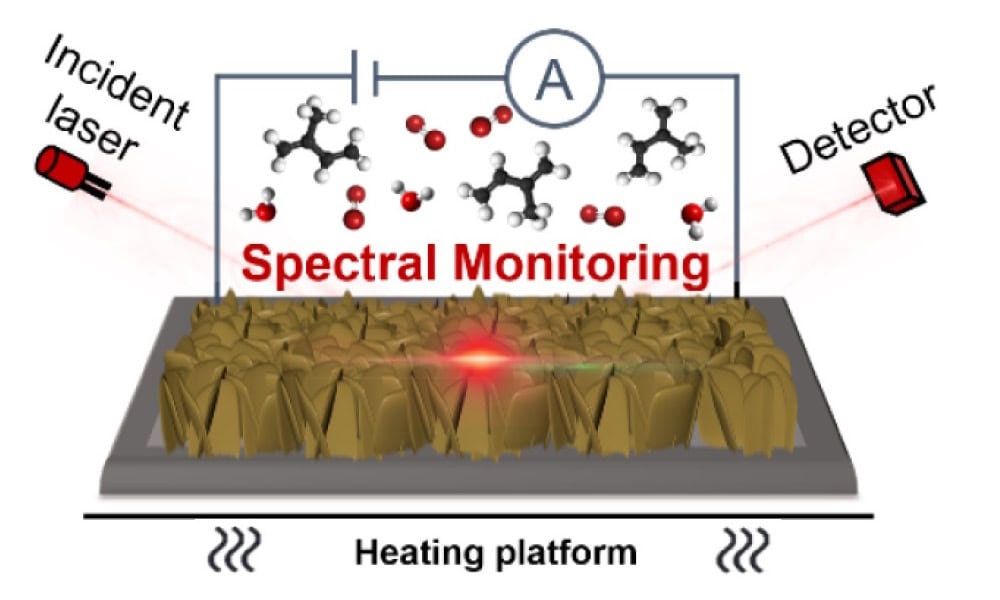

To optimize the sensing performance, the research team – led by Pingwei Liu from Zhejiang University and Qingyue Wang from Institute of Zhejiang University – developed a series of sensors made from nanoflakes of pure In2O3, nickel-doped (InNiOx) or platinum-loaded (Pt@InNiOx). The sensors comprise an insulating substrate with interdigitated gold/titanium electrodes, coated with a layer of roughly 10 nm-thick nanoflakes. When the sensor is exposed to isoprene, adsorption of isoprene onto the nanoflakes causes an increase in the detected electrical signal.

“The nanoflakes’ two-dimensional structure provides a relatively high surface area and pore volume compared with the bulk structure, thus promoting isoprene adsorption and enhancing electron interaction and electrical signals,” Wang explains. “This improves the sensitivity of the gas sensor.”

The researchers – also from Second Affiliated Hospital, Zhejiang University School of Medicine and Instituto de Catálisis y Petroleoquímica, CSIC – assessed the isoprene sensing performance of the various sensor chips. All three exhibited a linear response to isoprene concentrations ranging from 500 ppb to the limit-of-detection (LOD) at the operating temperature of 200 °C. Pt@InNiOx showed a response at least four times higher than InNiOx and In2O3, as well as an exceptionally low LOD of 2 ppb, greatly outperforming any previously reported sensors.

The Pt@InNiOx sensor also showed high selectivity, exhibiting 3–7 times higher response to isoprene than to other volatile organic compounds commonly found in breath. Pt@InNiOx also exhibited good repeatability over nine cycles of 500 ppb isoprene sensing.

The team next examined how humidity affects the sensors – an important factor as exhaled breath usually has a relative humidity above 65%. The InNiOx and Pt@InNiOx sensors maintained a stable current baseline in the presence of water vapour. In contrast, the In2O3 sensor showed more than a 100% baseline increase. Similarly, the isoprene sensing performance of InNiOx and Pt@InNiOx was unaffected by water vapor, while the In2O3 response decreased to less than 0.5% as relative humidity reached 80%.

The team also used simultaneous spectroscopic and electrical measurements to investigate the isoprene sensing mechanism. They found that nanoclusters of platinum in the nanoflakes play a pivotal role by catalysing the oxidation of isoprene C=C bonds, which releases electrons and triggers the isoprene-sensing process.

Clinical testing

As the performance tests indicated that Pt@InNiOx may provide an optimal sensing material for detecting ultralow levels of isoprene, the researchers integrated Pt@InNiOx nanoflakes into a portable breath sensing device. They collected exhaled breath from eight healthy individuals and five lung cancer patients, and then transferred the exhaled gases from the gas collection bags into the digital device, which displays the isoprene concentration on its screen.

The sensing device revealed that exhaled isoprene concentrations in lung cancer patients were consistently below 40 ppb, compared with more than 60 ppb in healthy individuals. As such, the device successfully distinguished individuals with lung cancer from healthy people.

“These findings underscore the effectiveness of the Pt@InNiOx sensor in real-world scenarios, validating its potential for rapid and cost-effective lung cancer diagnosis,” the researchers write. “Integrating this ultrasensitive sensing material into a portable device holds significant implications for at-home surveillance for lung cancer patients, enabling dynamic monitoring of their health status.”

Ultrasensitive frequency comb breathalyser targets real-time disease diagnosis

Looking to future commercialization of this technology, the researchers note that this will require further research on the sensing materials and the relationship between breath isoprene levels and lung cancer. “By addressing these areas and finishing the rigorous clinical trials, breath isoprene gas sensing technology could become a transformative tool in the noninvasive detection of lung cancer, ultimately saving lives and improving healthcare,” they conclude.

“Currently, we’re cooperating with a local hospital for large-scale clinical testing and evaluating the potentials to be applied for other cancers such as prostate cancer,” Wang tells Physics World.

The researchers report their findings in ACS Sensors.