Researchers in the US have unveiled a new high-temperature material that is 60% better at converting heat to electricity than comparable “thermoelectrics”. The material, which is a nanocomposite, is stable up to temperatures as high as 700 °C. It could therefore potentially be used to boost the fuel efficiency of cars by recovering energy from the vehicle’s exhaust heat.

As materials that can convert heat directly into electricity, thermoelectrics sound highly promising to reduce global energy consumption. In addition to possibly finding their way into cars, they could also be used to recover useful energy from waste heat from nuclear reactors. Other applications including improving the effectiveness of solar cells and cooling computer chips and other electronic devices.

To be of practical use, however, a thermoelectric material must be good at conducting electricity but poor at conducting heat. It must also have a large thermopower, which is the ratio of the voltage to temperature difference across a material to its temperature difference. These three requirements are expressed in the thermoelectric figure of merit ZT. Any practical material must also operate at the appropriate ambient temperature, which in the case of vehicle exhausts can be hundreds of degrees.

Go with the grain

One promising group of thermoelectric materials are the “half-Heuslers”, which are robust alloys of several metallic elements. They do suffer, however, from having relatively high thermal conductivities. One way of reducing their conductivity is to squish together a fine powder of the material to form a nanocomposite containing many tiny grains. Heat has a hard time travelling across the boundaries between grains, thereby reducing the overall thermal conduction of the nanocomposite.

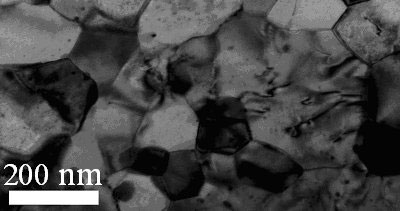

Now, Xiao Yan and colleagues at Boston College, MIT, the University of Virginia and Clemson University have used this technique on an extremely fine powder, producing a nanocomposite with the best ZT yet for a half-Heusler. The team began with a cast ingot of the half-Heusler Zr0.5Hf0.5CoSb0.8Sn0.2, which was then crushed to make a powder with a particle size between 5 and 10 nm. Heat and pressure were then applied to press the powder into millimetre-sized bars and discs. This was done very carefully to try to minimize the number of nanoparticles that fuse together to create much larger grains in the finished product.

The resulting solid had an average grain size of 100–200 nm. While this was larger than the original powder, it was about one-tenth the grain size of previous attempts at making similar materials. By measuring the thermopower of the nanocomposite along with its electrical and thermal conductivities, the team found that it had a ZT of 0.8 at temperatures of 700 °C, which is about 60% higher than the best previous value for a half-Heusler thermoelectric.

Off the gas

One reason for the high ZT was that the thermal conductivity was about 30% less than the cast ingot from which it was made. The ZT value was also boosted by a small increase in the thermopower of the nanocomposite compared to the cast ingot. Both these effects more than compensated for the small measured drop in the electrical conductivity of the material, which – all other things being equal – would have reduced the ZT.

Yan told physicsworld.com that the increased thermopower is probably caused by the preferential scattering of lower-energy charge carriers at grain boundaries, which increases the mean carrier energy in the material.

While other thermoelectric materials have ZT values greater than 1.0, these tend to operate a lower temperatures than the half-Heuslers. Other advantages of the material, according to Yan are that it has excellent thermal stability and good mechanical strength and is non-toxic and inexpensive. That could be good news for drivers. “Assuming a ZT of 0.8, gas mileage could be improved by 10%,” Yan reckons. He also believes that half-Heuslers thermoelectrics could also be used to generate electricity from heat from the Sun.

Akram Boukai of the University of Michigan in the US agrees that half-Heuslers are good candidates for vehicle-exhaust applications. “Half-Heusler materials have great potential for power generation since you can tune their electronic and thermal properties at will,” he says. Boukai, who was not involved in this latest work, adds that Yan’s research “achieves a remarkable improvement in efficiency by nanostructuring the bulk material”.

As well as optimizing the chemical composition of the half-Heusler, the team is looking at how to reduce the grain size of the pressed material. “Even lower thermal conductivity and higher ZT could be expected if grain size could be kept below 100 nm during pressing,” explained Yan.