Printed electronics are viewed as a cost-effective and scalable route to new technologies, although the performance of these devices tends to rely less on the printer and more on the ink. Researchers at Trinity College Dublin, in collaboration with scientists at Delft University of Technology and Toyota Motor Europe, have now fabricated vertically stacked thin-film transistors (TFTs) from dispersions of two-dimensional nanosheets. Combining high performance with ease of manufacture, these nanosheet-based TFTs have the potential to compete with organic and nanotube-based electronics.

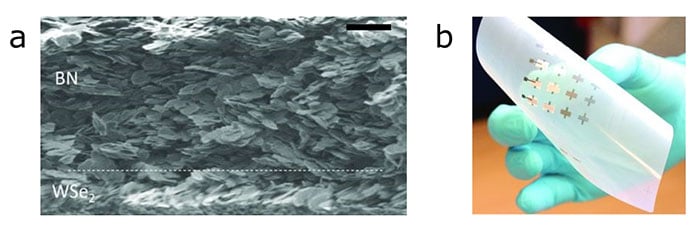

The nanosheet inks are made using a process known as liquid-phase exfoliation, where layered materials in bulk form are broken down and dispersed in liquids. Over the last 10 years this has become an established method for efficiently producing a whole library of two-dimensional materials. Due to the widely varying properties of these nanosheets, every component in the TFT can be printed: conducting graphene nanosheets are used for the electrodes, semiconducting transition-metal dichalcogenides such as molydenum disulphide or tungsten diselenide form the channel, and a boron nitride (BN) dielectric layer acts as a separator.

When printed, the inks form porous nanosheet networks (PNNs) that can be printed layer-by-layer. Their high porosity allows for the use of electrolytic gating, where liquid electrolyte contained within the network is used as a gate dielectric. During operation, ions in the liquid accumulate at the boundary between the electrolyte and the active material due to the application of a gate voltage. Charged ions at the interface then separate, forming an electrostatic double layer and inducing current to flow through the external circuit.

The research team, led by Adam Kelly and Toby Hallam, measured the electrical transport characteristics of different PNNs using a simple set up involving gold electrodes and an ionic liquid electrolyte (Science 356 6333 69). They found that the transconductance, a measure related to the gain a transistor is capable of delivering, is directly proportional to the thickness of nanosheet network. This allows the electrical characteristics of the device to be tuned by their printing conditions, with transconductance values as high as 6 mS reported by the team.

Large capacitance values were also measured for thick PNNs, due to the large amount of free volume available for ion adsorption. This gives these devices transport properties similar to those of benchmark TFTs, though such high capacitances do hinder switching times. Fortunately, the researchers believe that further experimentation with the ionic liquid electrolyte will enhance switching speeds.

Building on these results, the team built a fully functional TFT using only porous nanosheet networks: graphene electrodes, a tungsten diselenide channel and a BN separator. These vertically stacked devices have on:off ratios of more than 25 and a transconductance of 22 μS. Such transfer characteristics are promising for devices that are still the early stages of development, and further improvements should be possible in the future.

Full details are reported in Science.