Researchers in the UK and Korea have used carbon nanotubes to make a nano-scale electromechanical switch for the first time. The relatively simple method used to make the switch could become a standard way for fabricating nano-scale devices in the future (Appl. Phys. Lett. 87 163114).

An electromechanical system is a device in which a mechanical element moves in response to an external force. The new nanoelectromechanical system (NEMS) made by Jae Eun Jang of Cambridge University and co-workers at Cambridge, Sungkyunkwan University and Samsung is driven mainly by electrostatic forces, although Van der Waals forces also come into play.

Unlike conventional electronic devices, it might be possible to routinely manufacture NEMS to high tolerances on the scale of nanometres (10-9 metres). Such devices would rely on carbon nanotubes — rolled up sheets of graphite just nanometres in diameter that have excellent mechanical and electrical properties. However, until now most NEMS have been completely made using complicated lithography and etching techniques.

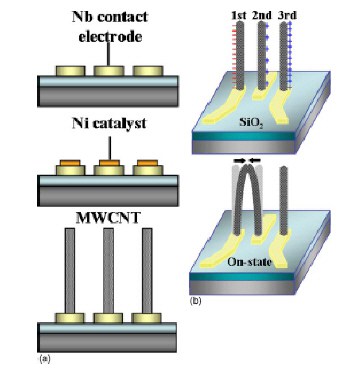

Jang and co-workers started by defining an underlying three-electrode structure with lithography, and then used electron-beam lithography and a “lift-off” technique to define nickel dots about 100-nm across on the electrodes. Finally, the team grew vertical nanotubes on top of the dots (see figure).

The underlying electrodes are then electrically biased so that one nanotube (the source electrode) is earthed and while the other (the drain) is positively biased. A third electrode — which might or might not have a carbon nanotube on it — close to the drain acts as the gate electrode. As the gate voltage becomes more biased, a threshold voltage is reached where the repulsive electrostatic force felt by the drain nanotube moves it towards the source. When the drain nanotube touches the source, a current passes between the two electrodes and switches on the device.

Depending on the length of the nanotubes, the drain can stay attached to the source through Van der Waals interactions (the “on” position), or spring back to the original “off” position when the gate voltage is reduced below the threshold. Jang and colleagues have shown that the switching behaviour can be controlled by varying the length of the nanotubes so that the balance between electrostatic and Van der Waals forces changes.

“The new switch could be used to replace all electronic switches in certain applications,” says Gehan Amaratunga, leader of the Cambridge team. “Its ability to hold either an ‘on’ or ‘off’ state when the driving voltage is removed also means it can be used in gripper or memory devices.”