Mobile phones, iPods and other portable electronics could someday be cooled by lightweight fins made of carbon nanotubes -- rather than the copper fins of today. That’s the claim of researchers in the US and Finland, who have worked out a way to attach arrays of these tiny carbon tubes to silicon chips using conventional manufacturing techniques. The nanotubes were found to dissipate heat at the same rate as copper, yet were ten times lighter as well as being stronger and more flexible. (Appl. Phys. Lett. 90 123105).

A carbon nanotube can be thought of as a sheet of carbon one atom thick that has been rolled up to make a nanometre-diameter cylinder. Despite being very lightweight, nanotubes are extremely strong and flexible. They are also conduct heat and electricity very well, which is why there have been many attempts to develop electronic devices from nanotubes since they were first discovered in the early 1990s. However, the use of nanotubes to conduct and dissipate heat has been largely ignored.

This opportunity has been seized by Robert Vajtai and colleagues at Rensselaer Polytechnic Institute in New York along with Krisztian Kordás and co-workers at Finland’s Oulu University, who have created the first nanotube cooling fins for silicon chips.

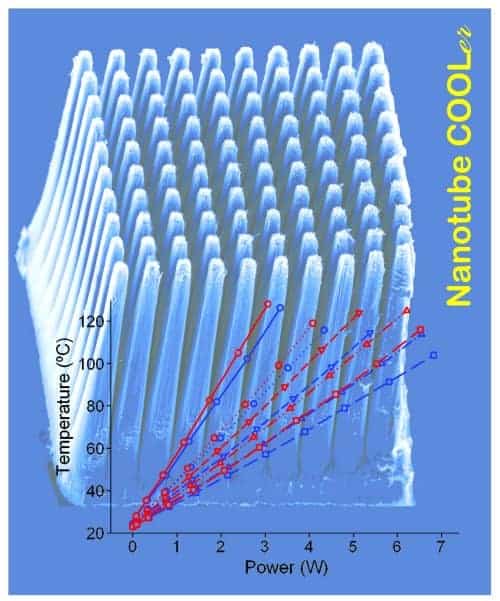

The fins were made by first growing a film of multi-walled nanotubes (several carbon tubes nested inside one another) on a silicon substrate. The individual nanotubes pointed out of the substrate surface and were about 1.2 mm long and varied in diameter from 10-90 nm. The nanotube film was then detached from the substrate and a laser was used to systematically remove nanotubes from the film to create 10×10 arrays of nanotube “fins”. The fins were pyramid-shaped structures each containing a large number of individual nanotubes (see figure).

The arrays were then soldered to silicon “flip chips”, which are used in portable and automotive electronics. Despite being knocked about during the assembly process, the nanotubes came through unscathed and their cooling capabilities were on par with copper structures. Indeed, Vajtai told Physics Web that the nanotubes proved to be much more robust than the delicate copper structures that are currently used to make light-weight cooling fins.

Vajtai said that the group is currently trying to boost the performance of the fins, which he believes could reach ten times the heat dissipation of copper fins. This could be done by using higher-quality nanotubes and through the careful optimization of the overall structure of the arrays in terms of the size and spacing of the fins. He also believes that nanotube cooling fins could someday be manufactured at a cost of about one cent per device cooled, which is comparable to existing technologies.