A new approach for fabricating multilayer neutron mirrors has been developed by researchers in Sweden. By adding boron carbide to the iron and silicon layers of their mirror, Anton Zubayer at Linköping University and colleagues created a device that is more reflective and polarizing to incoming neutron beams, especially at high scattering angles.

Neutron science involves scattering beams of slow-moving neutrons from samples. Such neutrons have de Broglie wavelengths on par with the separation between atoms in solids, liquids and gases. This means that the diffraction of neutron beams can be used to determine the atomic structure of a sample. Neutrons can exchange kinetic energy with atoms, so they can also probe dynamic properties of matter such as lattice vibrations. Neutrons also have magnetic moments so they can measure magnetic properties of samples.

Some magnetic neutron scattering experiments require beams that are magnetically polarized, but creating such beams can be a challenge.

“Polarizing neutron optics is an essential part for neutron scattering facilities,” Zubayer explains. “It is gaining in importance as new types of instrument demand greater efficiency and novel features.”

Poor interfaces

Neutron beams can be polarized using mirrors that are made by depositing alternating layers of iron and silicon on a substrate. Despite their widespread use, these neutron mirrors have limitations that are associated with the difficulty of creating atomically sharp interfaces between the iron and silicon layers. Instead, the interfaces contain unwanted iron silicide compounds.

These rough interfaces mean that at higher scattering angles, the mirrors are not very effective at reflecting and polarizing neutrons. This can be overcome by exposing the mirrors to strong external magnetic fields – but since these fields can also affect the samples being studied, the mirrors need to be placed some distance away from the samples and this can diminish the quality of the experimental results.

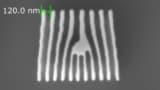

Now, Zubayer and colleagues have taken a new approach to fabricating neutron mirrors, which involves adding isotope-enriched boron carbide to the iron and silicon layers. The boron carbide is enriched with boron-11 – which unlike boron-10, is not a good absorber of neutrons. The compound improves the stability of materials deposited through magnetron sputtering, which was used to deposit the layers.

After building up the layers of their neutron mirror, Zubayer and colleagues determined its atomic structure using several different imaging techniques including X-ray diffraction and electron microscopy.

Thinner and sharper

As they hoped, their new mirror featured far sharper interfaces between the iron and silicon layers and less iron silicide. This allowed the layers to be made thinner than before, making the mirror far more reflective and polarizing to neutron beams at high scattering angles. It also led to less diffuse scattering within the beams.

Twisted neutrons are created using a holographic approach

With this improved performance, Zubayer’s team no longer needed to use an external magnetic field to achieve the desired polarization. As a result, their mirror could be placed closer to samples without affecting measurements.

“We have realised a higher reflectivity, better polarization, less background noise for the beamline, and eliminate the need for large magnets around the device,” Zubayer explains. “Thus, such optics using our approach could unlock new efficiencies and possibilities, leading to better, faster, more reliable, and maybe even new types of experiments.”

With these improvements, researchers could increase the polarized neutron flux used in experiments as well as the use of higher-energy neutrons. The team hopes their new approach could pave the way for new experimental discoveries across fields spanning physics, chemistry, biology, and medicine.

The research is described in Science Advances.