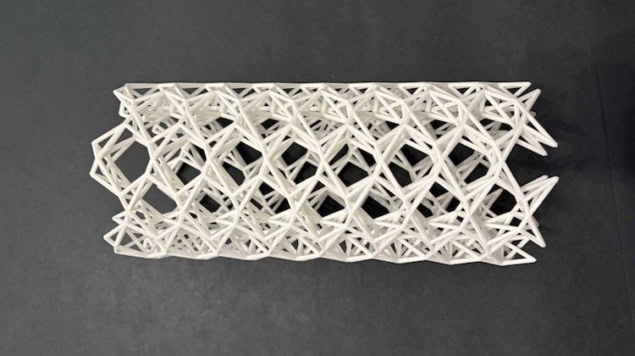

A 3D-printed structure called a kagome tube could form the backbone of a new system for muffling damaging vibrations. The structure is part of a class of materials known as topological mechanical metamaterials, and unlike previous materials in this group, it is simple enough to be deployed in real-world situations. According to lead developer James McInerney of the Wright-Patterson Air Force Base in Ohio, US, it could be used as shock protection for sensitive systems found in civil and aerospace engineering applications.

McInerney and colleagues’ tube-like design is made from a lattice of beams arranged in such a way that low-energy vibrational modes called floppy modes become localized to one side. “This provides good properties for isolating vibrations because energy input into the system on the floppy side does not propagate to the other side,” McInerney says.

The key to this desirable behaviour, he explains, is the arrangement of the beams that form the lattice structure. Using a pattern first proposed by the 19th century physicist James Clerk Maxwell, the beams are organized into repeating sub-units to form stable, two-dimensional structures known as topological Maxwell lattices.

Self-supporting design

Previous versions of these lattices could not support their own weight. Instead, they were attached to rigid external mounts, making it impractical to integrate them into devices. The new design, in contrast, is made by folding a flat Maxwell lattice into a cylindrical tube that is self-supporting. The tube features a connected inner and outer layer – a kagome bilayer – and its radius can be precisely engineered to give it the topological behaviour desired.

The researchers, who detail their work in Physical Review Applied, first tested their structure numerically by attaching a virtual version to a mechanically sensitive sample and a source of low-energy vibrations. As expected, the tube diverted the vibrations away from the sample and towards the other end of the tube.

Next, they developed a simple spring-and-mass model to understand the tube’s geometry by considering it as a simple monolayer. This modelling indicated that the polarization of the tube should be similar to the polarization of the monolayer. They then added rigid connectors to the tube’s ends and used a finite-element method to calculate the frequency-dependent patterns of vibrations propagating across the structure. They also determined the effective stiffness of the lattice as they applied loads parallel and perpendicular to it.

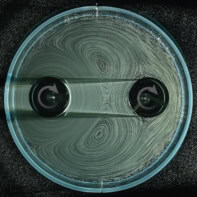

Loopy currents appear in a kagome superlattice

The researchers are targeting vibration-isolation applications that would benefit from a passive support structure, especially in cases where the performance of alternative passive mechanisms, such as viscoelastomers, is temperature-limited. “Our tubes do not necessarily need to replace other vibration isolation mechanisms,” McInerney explains. “Rather, they can enhance the capabilities of these by having the load-bearing structure assist with isolation.”

The team’s first and most important task, McInerney adds, will be to explore the implications of physically mounting the kagome tube on its vibration isolation structures. “The numerical study in our paper uses idealized mounting conditions so that the input and output are perfectly in phase with the tube vibrations,” he says. “Accounting for the potential impedance mismatch between the mounts and the tube will enable us to experimentally validate our work and provide realistic design scenarios.”