A new synthetic hydrogel that becomes up to 50 times stiffer upon heating just a few degrees has been developed by researchers at Radboud University in the Netherlands. The stiffening process is reversible, and the team believes that the hydrogel could be used in a range of new applications including tissue engineering.

The controlled stiffening or softening of materials is very common in biology, playing roles in processes such as muscle contraction, tissue fibrosis, the enzymatic degradation of tissues and tumour formation. It involves a biological cell converting chemical energy into mechanical stresses, which cause the cell’s cytoskeleton to stiffen with stress. However, mimicking this ability to stiffen and soften in a synthetic material such as a hydrogel has proven very tricky to achieve.

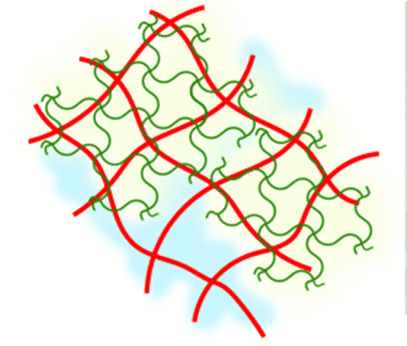

Hydrogels are flexible materials made from crosslinked polymers. Most hydrogels are either soft or stiff depending on their composition. To reduce the stiffness of a given crosslinked network, some crosslinks must be broken. Conversely, stiffness is increased by boosting the number of crosslinks. Either way, a large stimulus is needed to break or create bonds and these processes are often not easily reversible.

Entirely new mechanism

Now researchers led by Radboud’s Paul Kouwer have developed a synthetic hydrogel that can change its stiffness in a reversible way. “We implement an entirely new mechanism, which makes our approach so interesting,” explains Kouwer. “We do not create any new crosslinks in order to stiffen our hydrogel. What we have instead is a material that is sensitive to stress – a property very common in biology but not in synthetic materials.”

Their material consists of two types of polymers interlaced to create an interpenetrating network. One polymeric component is polyisocyanide (PIC), which responds to stress. The other component is poly(N-isopropylacrylamide) (PNIPAM), which responds changes in temperature.

Heating the material by just one degree causes the temperature-sensitive PNIPAM network to undergo a sharp structural transition that the team describes as a collapse. This puts stress on the PIC polymer chains, causing them to stiffen.

“The collapse of one component creates internal stresses that induce a highly nonlinear response in the second component. Increasing the temperature by only one degree induces a very sharp phase transition in the first material and creates a strain stiffening effect in the second one,“ says Kouwer.

The material can become 50-times more stiff and the effect is reversible and can be repeated up to 10 times with excellent reproducibility.

Muscling in

The contraction intensity and forces measured in the new hydrogel are similar to the contraction of a real muscle. Indeed, muscles contain actin fibres that are attached to myosin fibres, which are contracted by myosin motors. Therefore, the stress created by the collapsing PNIPAM network in the hydrogel is playing a role similar to that of the myosin motor.

An important difference, however, is that muscle fibres are aligned in a specific direction whereas fibres in the hydrogel are not aligned. So unlike a muscle, the hydrogel does not contract in one direction.

“If your system is aligned, it would contract in one direction too. On the other hand, our system is a 3D isotropic material. This means that the stiffening effect cannot be seen on a macroscopic level, as it would happen in all possible directions at once,“ says Kouwer. “We realized that if we could guide the direction of stiffening, we would be able to design a real muscle mimic.”

Tissue growth

The team is already working on aligning the polymer chains in their hydrogel. Future work could include creating materials that react to light rather than changes in temperature.

One potential application for such hydrogels is to use them as synthetic matrices that encourage living cells to combine to create artificial tissues in the lab. Local and time-controlled changes in the hydrogel could potentially control the behaviour of the growing cells – a feature crucial for tissue engineering and the growth of artificial organs.

Hydrogel material flexes its muscles

“Placing cells into a stiffer environment could make them respond by expressing different proteins or change their growth rate. This area is currently completely unknown. Theoretically, this could create an entire new field in tissue engineering,” explains Kouwer.

Gijsje Koenderink from AMOLF research institute in Amsterdam, who was not involved in this study, believes that next challenge in developing the material will be to replace the temperature-sensitive gel, which requires external energy input in the form of heating, with a molecularly active source of stress. “Synthetic chemistry has already achieved synthetic mimics in the form of active polymers and synthetic molecular motors,” she says. “The next challenge is therefore to combine such mechanoactive molecules with materials and use them to drive life-like mechanoadaption.”

The new hydrogel is described in Nature Communications.