Scientists in the US have invented a new type of material consisting of graphene sheets -- thin films of carbon that are just one atom thick -- embedded in a polymer matrix. The composites, which conduct elecricity, could be used to make new types of microelectronics devices and circuits, as well as find use in aircraft and coatings (Nature 442 282).

Graphene — a novel type of material with good electrical properties — can be made by rubbing tiny pieces of its precursor, graphite, against a hard surface to detach flakes of the carbon material. However, this is not an easy process because the individual sheets tend to clump together. Moreover, graphite, is soft and flaky and so does not have the high mechanical strength of carbon nanotubes.

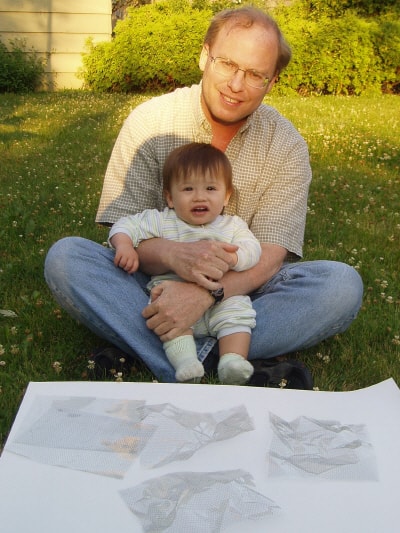

One way of making graphene more useful is to embed the graphene in a polymer matrix. However, this has not been easy because the individual sheets attract each other so strongly that they cannot be properly dispersed in a polymer solution. Rodney Ruoff at Northwestern University in Illinois and colleagues have now devised a new technique to overcome these problems.

The team began by converting graphite into graphite oxide in an aqueous solution. This familiar process adds oxygen-based chemical groups to the graphite surface and leads to the bulk graphite being completely separated into single sheets. The sheets remain separate because they repel each other thanks to the oxygen-based chemical groups, which have an excess negative charge.

The researchers then “tuned” the surface of the graphite by adding certain chemical gropus so that it disperses in solvents routinely used to dissolve polymers. In this way, different polymers can be added to the solvent-graphite oxide mixture to make a composite material. The solvent is eventually removed to leave just the well-dispersed graphene sheets and polymer.

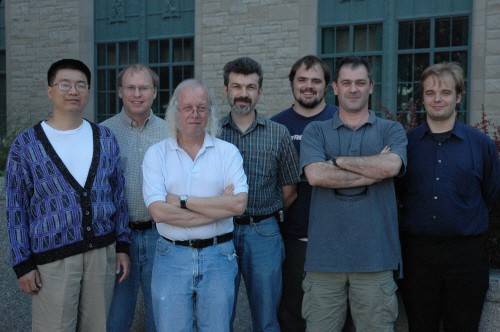

Using electron microscopy, Ruoff and co-workers observed that the polystyrene-graphene composite resembles a block of ice containing pieces of crumpled paper (figure 1). He believes the new material, which is light but stiff and tough, could be used to make fuselages for aircraft, as well as in electronics and potentially in paints and coatings.