Montana Instruments’ Cryostation 200 PT employs a pulse-tube cryocooler and innovative design to deliver shorter cooling times and larger experimental payloads

The development of advance quantum materials and devices often involves making measurements at very low temperatures. This is crucial when developing single-photon emitters and detectors for quantum technologies. And even if a device or material will not be used at cryogenic temperatures, researchers will sometimes make measurements at low temperatures in order to reduce thermal noise.

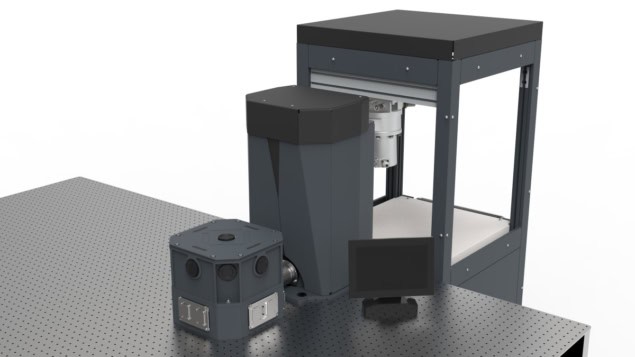

This R&D will often involve optical techniques such as spectroscopy and imaging, which use lasers and free-space optics. These optical systems must remain in alignment to ensure the quality and repeatability of the measurements. Furthermore, the vibration of optical components must be kept to an absolute minimum because motion will degrade the performance of instrumentation.

Minimizing vibration is usually achieved by doing experiments on optical tables, which are very large, heavy and rigid in order to dampen motion. Therefore, when a cryogenic cooler (cryocooler) is deployed on an optical table it is crucial that it does not introduce unwanted vibrations.

Closed-cycle cryocoolers offer an efficient way to cool samples to temperatures as low as ~2 K to 4 K (−272 °C to −269 °C). Much like a domestic refrigerator or air conditioner, these cryocoolers involve the cyclic compression and expansion of a gas – which is helium in cryogenic systems.

In 2010 Montana Instruments founder Luke Mauritsen, a mechanical engineer and entrepreneur, recognized that the future development of quantum materials and devices would rely on optical cryostats that allow researchers to make optical measurements at very low temperatures and at very low levels of vibration. To make that possible, Mauritsen founded Montana Instruments, which in 2010 launched its first low-vibration cryostats. Based in Bozeman, Montana, the company was acquired by Sweden’s Atlas Copco in 2022 and it continues to develop cryogenic technologies for cutting-edge quantum science and other demanding applications.

Until recently, all of Montana’s low-vibration optical cryostats used Gifford–McMahon (GM) cryocoolers. While these systems provide low temperatures and low vibrations, they are limited in terms of the cooling power that they can deliver. This is because operating GM cryocoolers at higher powers results in greater vibrations.

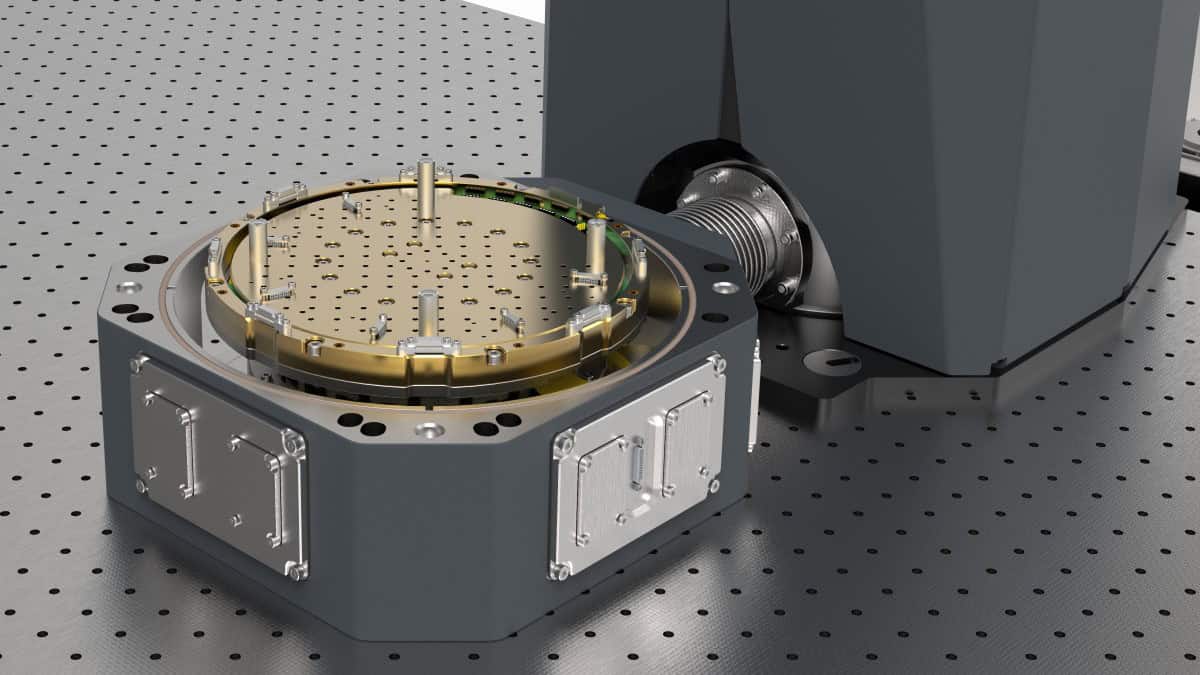

To create a low-vibration cryostat with more cooling power, Montana has developed the Cryostation 200 PT, which is the first Montana system to use a pulse-tube cryocooler. Pulse tubes offer similar cooling powers to GM cryocoolers but at much lower vibration levels. As a result, the Cryostation 200 PT delivers much higher cooling power, while maintaining very low vibrations on par with Montana’s other cryostats.

Montana’s R&D manager Josh Doherty explains, “One major reason that a pulse tube has lower vibrations is that its valve motor can be ‘remote’, located a short distance from coldhead of the cryostat. This allows us to position the valve motor, which generates vibrations, on a cart next to the optical table so its energy can be shunted to the ground, away from the experimental space on the optical table.”

However, isolating the coldhead from the valve motor is not enough to achieve the new cryostat’s very low levels of vibration. During operation, helium gas moves back and forth in the pulse tube and this causes tiny vibrations that are very difficult to mitigate. Using its extensive experience, Montana has minimized the vibrations at the sample/device mount and has also reduced the vibrational energy transferred from the pulse tube to the optical table. Doherty explains that this was done using the company’s patented technologies that minimize the transfer of vibrational energy, while at the same time maximizing thermal conductance between the pulse tube’s first stage and second stage flanges and the sample/device mounting surface(s). This includes the use of flexible, high-thermal-conductivity links and flexible vacuum bellows connections between the coldhead and the sample/device.

Doherty adds, “we intentionally design the supporting structure to de-tune it from the pulse tube vibration source”. This was done by first measuring the pulse-tube vibrations in the lab to determine the vibrational frequencies at which energy is transferred to the optical table. Doherty and colleagues then used the ANSYS engineering/multiphysics software to simulate designs of the pulse tube support and the sample mount supporting structures.

“We optimized the supporting structure design, through material choices, assembly methods and geometry to mismatch the simulated natural frequencies of the support structure from the dominant vibrations of the source,” he explains.

As a result, the Cryostation 200 PT delivers more that 250 mW cooling power at 4.2 K, with a peak-to-peak vibrational amplitude of less than 30 nm. This is more than three times the cooling power delivered by Montana’s Cryostation s200, which offers a similarly-sized sample/device area and vibrational performance.

The control unit has a touchscreen user interface, which displays the cryostat temperature, temperature stability and vacuum pressure.

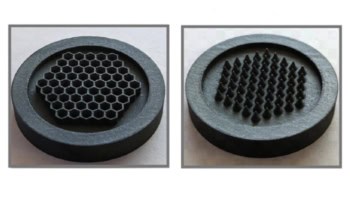

The cryostat has multiple feedthrough options that support free-space optics, RF and DC electrical connections, optical fibres and a vacuum connection. The Cryostation 200 PT supports Montana’s Cryo-Optic microscope objective and nanopositioner, which can be integrated within the cryostat. Also available is a low working distance window, which supports the use of an external microscope.

According to Montana Instrument senior product manager Patrick Gale, the higher cooling power of the Cryostation 200 PT means that it can support larger experimental payloads – meaning that a much wider range of experiments can be done within the cryostat. For example, more electrical connections can be made with the outside world than had been possible before.

“Every wire that you bring into the cryostat increases that heat load a little bit,” explains Gale, adding, “By using a 1 W pulse tube, we can cool the system down faster than any of our other systems”. While Montana’s other systems have typical cooling times of about 10 h, this has been reduced to about 6 h in the Cryostation 200. “This is particularly important for commercial users who are testing multiple samples in a week,” says Gale. “Saving that four hours per measurement allows a user to do two tests per day, versus just one per day.”

According to Gale, applications of the Cryostation 200 PT include developing ion traps for use in quantum computing, quantum sensing and atomic clocks. Other applications related to quantum technologies include the development of photonic devices; spin-based devices included those based on nitrogen-vacancies in diamond; quantum dots; and superconducting circuits.