This article reports on research described in a paper in Nature Communications that was retracted on 23 October at the request of its authors due to an error in converting the magnetic units involved in calculating the current density of their material.

A superconducting wire segment based on rare-earth barium copper oxide (REBCO) is the highest performing yet in terms of current density, carrying 190 MA/cm2 in the absence of any external magnetic field at a temperature of 4.2 K. At warmer temperatures of 20 K (which is the proposed application temperature for magnets used in commercial nuclear fusion reactors), the wires can still carry over 150 MA/cm2. These figures mean that the wire, despite being only 0.2 micron thick, can carry a current comparable to that of commercial superconducting wires that are almost 10 times thicker, according to its developers at the University at Buffalo in the US.

High-temperature superconducting (HTS) wires could be employed in a host of applications, including energy generation, storage and transmission, transportation, and in the defence and medical sectors. They might also be used in commercial nuclear fusion, offering the possibility of limitless clean energy. Indeed, if successful, this niche application could help address the world’s energy supply issues, says Amit Goyal of the University at Buffalo’s School of Engineering and Applied Science, who co-led this new study.

Record-breaking critical current density and pinning force

Before such large-scale applications see the light of day, however, the performance of HTS wires must be improved – and their cost reduced. Goyal and colleagues’ new HTS wire has the highest values of critical current density reported to date. This is particularly true at lower operating temperatures ranging from 4.2–30 K, which is of interest for the fusion application. While still extremely cold, these are much higher than the absolute zero temperatures that traditional superconductors function at, says Goyal.

And that is not all, the wires also have the highest pinning force (that is, the ability to hold magnetic vortices) ever reported for such wires: around 6.4 TN/m3 per cubic metre at 4.2 K and about 4.2 TN/m3 at 20 K, both under a 7 T applied magnetic field.

“Prior to this work, we did not know if such levels of critical current density and pinning were possible to achieve,” says Goyal.

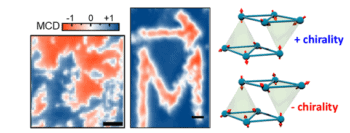

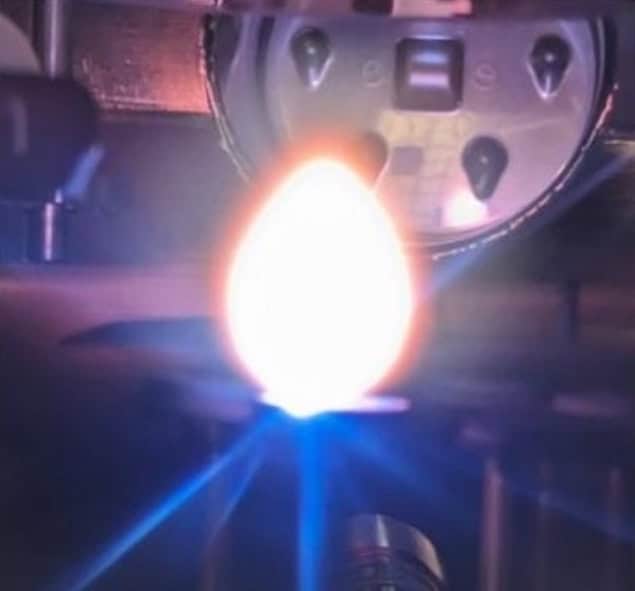

The researchers made their wire using a technique called pulsed laser deposition. Here, a laser beam impinges on a target material and ablates material that is deposited as a film on the substrate, explains Goyal. “This technique is employed by a majority of HTS wire manufacturers. In our experiment, the high critical current density was made possible thanks to a combination of pinning effects from rare-earth doping, oxygen-point defects and insulating barium zirconate nanocolumns as well as optimization of deposition conditions.”

This is a very exciting time for the HTS field, he tells Physics World. “We have a very important niche large-scale application – commercial nuclear fusion. Indeed, one company, Commonwealth Fusion, has invested $1.8bn in series B funding. And within the last 5 years, almost 20 new companies have been founded around the world to commercialize this fusion technology.”

REBCO high-temperature superconductors are ideal for tokamak magnets, study suggests

Goyal adds that his group’s work is just the beginning and that “significant performance enhancements are still possible”. “If HTS wire manufacturers work on optimizing the conditions under which the wires are deposited, they should be able to achieve a much higher critical current density, which will result in much better price/performance metric for the wires and enable applications. Not just in fusion, but all other large-scale applications as well.”

The researchers say they now want to further enhance the critical current density and pinning force of their 0.2 micron-thick wires. “We also want to demonstrate thicker films that can carry much higher current,” says Goyal.

They describe their HTS wires in Nature Communications.