Researchers at the Empa in Dübendorf, Switzerland, have made a high-performance supercapacitor entirely from recyclable, non-toxic materials. The device can withstand thousands of charge and discharge cycles, resists pressure and shock, and works even at freezing temperatures, making it an environmentally-friendly option for powering Internet of Things (IoT) devices.

The development of the IoT has heightened the already-difficult problem of electronic waste. Many electronic components for IoT applications are produced by the million, have a short service life and are powered by lithium-ion or alkaline batteries. While these batteries perform well, they contain toxic materials that need to be collected at the end of their life and then recycled using special processes.

Onto the compost heap

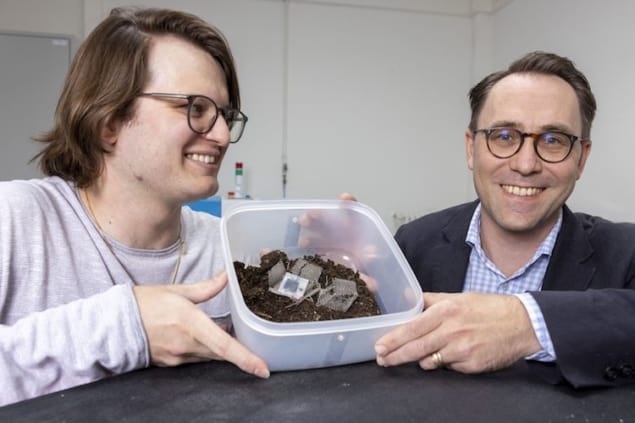

Researchers led by Gustav Nyström have now developed an alternative: an electric double-layer capacitor (EDLC) made from a disposable paper-like material. In the context of electronics, the researchers explain that “disposable” devices are those that can be thrown away in the trash, do not release toxic substances and ultimately fragment into small particles. “At the end of its service our new EDLC can be processed as a noncytotoxic compostable material or simply be left in nature,” says Xavier Aeby of Empa’s Cellulose & Wood Materials lab. “Indeed, the device disintegrates and loses 50% of its mass within nine weeks, leaving only a few visible carbon particles.”

The device, which can also store much more charge than a conventional capacitor, was made using a method called direct-ink writing. In this technique, viscoelastic gel ink is extruded line-by-line and layer-by-layer from a printer nozzle to form three-dimensional objects.

Nyström and colleagues’ ink contains only nontoxic and renewable materials: nanocellulose as a gelling and network-forming agent and as a substrate; carbon powder to make high-surface-area electrodes; glycerol as a plasticizer in the nanocellulose and as the electrolyte; and water as the solvent. The nanocellulose itself contains high-performance bio-nanofibres, which are a finer-scale version of the micron-sized fibres used to make paper.

While the recipe may sound relatively simple, it certainly wasn’t easy to develop. “It took an extended series of tests until all the parameters were right, and each of the components flowed reliably from the printer and the capacitor worked,” Aeby says. “As researchers, we don’t want to just fiddle about, we also want to understand what’s happening inside our materials.”

Ideal for the IoT

To test their device’s suitability for real-world applications, Nyström and colleagues printed an energy-storage circuit composed of six supercapacitors connected in series on a complex 3D surface. They found that this system stores electricity for several hours and is capable of powering a standard digital alarm clock.

Carbon-based inks make first fully recyclable transistors

In the future, Nyström and Aeby say that such capacitors could power a sensor or microtransmitter for hours after being charged using an electromagnetic field, making them ideal for IoT applications. The number of microdevices is also expected to increase as “point-of-care” diagnostics, such as self-testing devices for diabetics, come into more widespread use. “A disposable cellulose capacitor could be well-suited for these applications too,” Nyström says.

The researchers, who report their work in Advanced Materials, say they now plan to study ways to improve the amount of charge that can be stored in their supercapacitor – “ideally without sacrificing the non-toxicity requirement,” Nyström tells Physics World.