The March Meeting of the American Physical was cancelled, but here is an opportunity to learn about companies that would have been exhibiting products in Denver.

The last-minute decision by the American Physical Society (APS) to cancel its March Meeting came as quite a shock to the physics community – in particular the large number of delegates who had already travelled to Denver – but it was clearly the right thing to do in a rapidly worsening situation with COVID-19. To help continue scientific exchange, a number of initiatives have emerged over the last few weeks to enable researchers to share and discuss their latest results using online tools and forums.

Perhaps the most ambitious is the Virtual APS March Meeting, launched by the APS in collaboration with the community to enable presenters to host a virtual session or record and upload their talk. The APS is also encouraging researchers to add their presentations to the official scientific programme, with the idea that all the content will be synched across the two websites. Meanwhile, a number of community efforts have sprung up around particular interest groups, all of which the APS has listed on the meeting website.

As yet there is no online replacement for the technical exhibit, where more than 150 companies were preparing to share their expertise and to introduce their latest innovations in equipment, services, and software. Some of the notable product launches are highlighted below, plus you can also check out our previous round-up of technical developments that were due to be announced at the meeting.

Control instrumentation empowers quantum computing

Zurich Instruments has introduced the first commercial Quantum Computing Control System (QCCS), which provides all the hardware and software needed by researchers to scale up their experimental set-ups to a large number of qubits while also minimizing complexity. The QCCS makes all the necessary links between high-level quantum algorithms and their physical qubit implementation, and performs all critical tasks such as qubit initialization, control and readout, and real-time feedback to enable global error correction on quantum algorithms.

The QCCS combines three instruments, two of which are industry firsts: the UHFQA quantum analyzer for parallel qubit readout, and the PQSC programmable quantum system controller for component synchronization and control. Along with the HDAWG arbitrary waveform generator and the LabOne control software, these instruments work as one entity, the QCCS, that is scalable from 1 to 100 qubits.

The UHFQA quantum analyzer enables real-time parallel readout of up to 10 superconducting or spin qubits with high fidelity. The UHFQA features two signal inputs and two signal outputs, and achieves sub-nanosecond timing resolution together with a baseband operation over a frequency range of up to ±600 MHz. With its low-latency signal processing chain of matched filters, real-time matrix operations, and state discrimination, the UHFQA supports the development of quantum computing set-ups with 100 qubits and more.

The PQSC programmable quantum system controller enables precise synchronization of all the electronic components needed to control a quantum computer. Real-time communications links with low latency enable the PQSC to perform fast and automated qubit calibration routines. Researchers can program the PQSC to develop new processing solutions for rapid tune-up and error correction, optimized to work with different algorithms and computer architectures.

The HDAWG arbitrary waveform generator provides 8-channel, 16-bit signal generation with ultralow trigger latency – allowing for fast sequence branching to implement complex algorithms. Thanks to its synchronization feature, the PQSC can link 18 units for a total of 144 channels with a skew below 200 ps out of the box.

All instruments are accessed through the LabOne control software, which provides an intuitive and efficient interface to monitor and program the entire system, to control signals and to record the results of all experiments.

Full details are available on Zurich Instruments’ website, or contact info@zhinst.com to arrange a video call

Automation equips atomic force microscopy for industry

Park Systems has shown that an atomic force microscope (AFM) can deliver the high throughputs needed for industrial metrology applications, including the manufacture of semiconductor chips. Combining high-speed scanning with optical pattern recognition and automation software can deliver measurements up to five times faster than with conventional techniques, while still maintaining good image quality and a long tip lifetime.

The demonstration promises to address the metrology challenge facing the semiconductor industry as it moves to ever smaller feature sizes. Optical microscopy has reached its limits for inspecting nanoscale devices built on 7 nm and 14 nm chip architectures, while existing AFM techniques deliver the required resolution but remain too slow for routine use.

Park Systems believes that full automation of the AFM technique, in which software is used to control critical tasks such as tip exchange, data analysis, wafer handling and recipe optimization, offers a reliable and high-speed solution. In this approach, optical pattern recognition is used for positioning, while automated measurement routines can be configured to perform specific metrology tasks, such as a topography scan or roughness measurements.

Engineers at Park Systems have tested this automated AFM approach in a series of experiments designed to mimic common measurement scenarios. They used one of Park’s NX20 AFMs with the company’s XEA software to measure the surface roughness of a clean silicon wafer, as well as the sidewall angle of a feature on a patterned wafer.

High-frequency cantilevers were used to speed up the image scanning, which was combined with a non-contact mode that increases the number of scans that can be performed without needing to change the tip. The tests showed that it was possible to reduce the scan time by a factor of five, and that at least 1000 images could be recorded with no degradation in image quality.

Park Systems has been working with imec, the leading R&D and innovation hub for nanoelectronics and digital technologies, to show that automated AFM can be used as a metrology solution in the semiconductor industry, and a new joint project will address the current metrological challenges of continuously downscaling the geometrical dimensions of devices and 3D assembly stacking.

Visit the Park Systems’ website to find out more about its automated AFM solutions for industrial mterology.

Simple solvers for strongly correlated systems

HQS Quantum Simulations has released a free and easy to use platform to solve lattice models, which can be accessed at scce.quantumsimulations.de. Simply define a unit cell of your strongly correlated model system in one or two dimensions, add a small amount of information about the system size, and the platform will take care of the rest – including the distribution of the jobs to high-performance cloud computers.

The platform exploits self-consistent cluster embedding (SCCE) to solve large periodic problems. In the SCCE approach, a lattice model is solved iteratively with a combined system divided into a fully-interacting cluster coupled to a non-interacting bath. The simulation proceeds until the result is self-consistent.

This approach is similar to dynamical mean-field theory and density matrix embedding theory, and the company says that a detailed description of the method will be published in the near future. Now available in a beta version, HQS is actively working to expand its capabilities.

“Currently we use the density matrix renormalization group (DMRG) algorithm as the solver for the lattice model, but in the future we would like to replace it by using quantum computers.” says Michael Marthaler, managing director at HQS. “The number of operations to simulate lattice models is relatively small, while simulating lattice models for strongly correlated systems is very challenging for a classical computer. Therefore we feel that this will be one of the first applications for quantum computers.”

In this beta phase each user is granted 100 credits per month, which should be sufficient to gain familiarity with the platform. HQS is keen to capture user feedback on the beta verson, which will allow the company to prioritize the development of additional features, such as support for 3D lattices, access to all underlying parameters of the SCCE and DMRG solver, and access to the cloud-based tool via an API. The SCCE online platform does not yet support the purchasing of additional credits, but users who wish to test the software more extensively should contact HQS directly.

Access the beta version of the software at scce.quantumsimulations.de, and provide feedback via the company website or at info@quantumsimulations.de.

Cryogenic innovation enables simple scale-up for quantum experiments

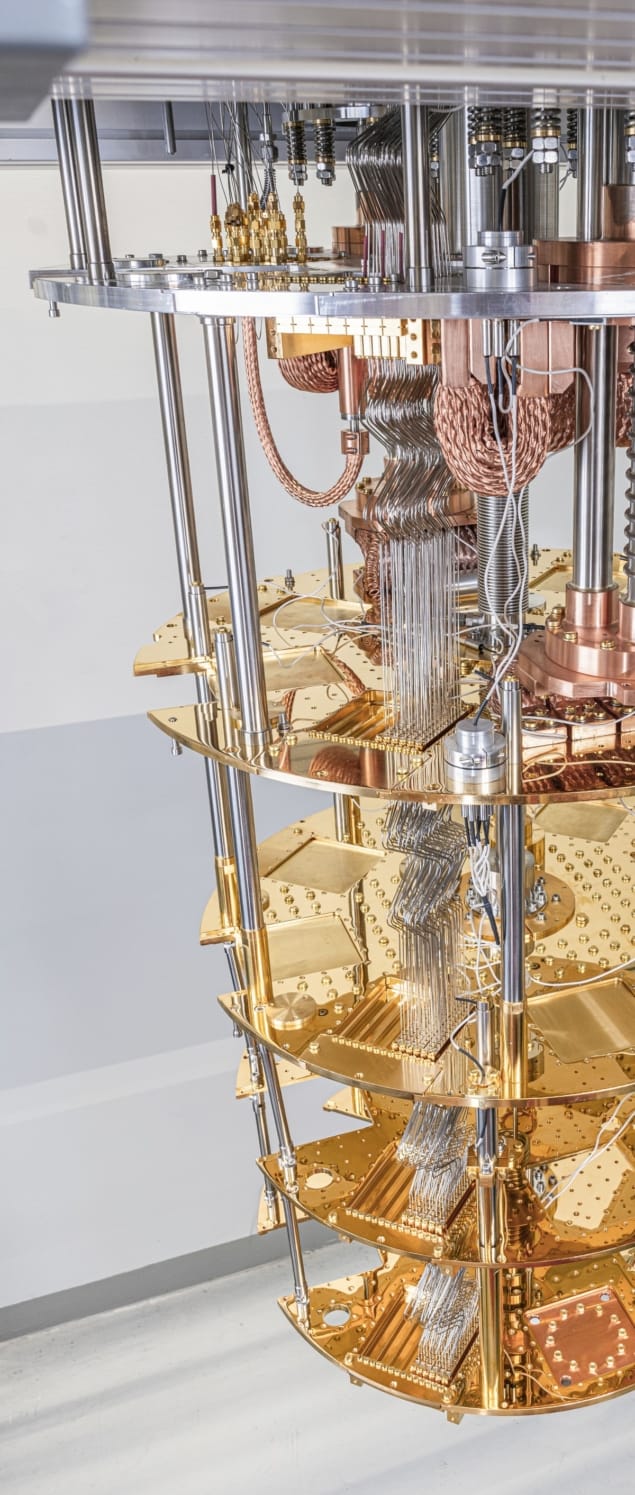

Bluefors has introduced high-density wiring as an option for its modular side-loading XLDsl dilution refrigerator system. The high-density interface enables researchers to build experiments with more than 1000 high-frequency lines in one cryostat, which is becoming increasingly important as scientists seek to increase the number of qubits in their quantum computing systems.

The interface exploits standard connectors and coaxial cables for the wiring, and the attenuators have been embedded in a single block that fits into the modular system. Wires are installed in blocks of 12 to help researchers ensure that each wire is connected securely. Meanwhile, the modular form factor allows the use of custom components with multiple high-density channels, such as amplifiers, filters and attenuators.

The high-density option forms part of Bluefors’ modular side-loading system, which provides a standard way for loading experiments into the cryostat. All the components and wiring needed for the experiment are assembled inside a module with a standard form factor that simply snaps into one of six side-loading ports on the XLDsl system, allowing for quick maintenance of complex assemblies.

“The modular system makes it possible to increase the number of wires and components in the system, allows rapid testing and troubleshooting, and ensures quick turn-around for busy multi-user environments,” says David Gunnarsson, Bluefors’ chief sales officer. “All this is done without compromising the thermal properties and strengths of the cryogenic system, which still keeps the operating temperature at milliKelvin temperatures.”

More information about high-density wiring in Bluefors’ modular side-loading system is available in the article Cool technology enables quantum computing.