German nanotechnology specialist attocube says its attoDRY800 cryostat enables quantum scientists to “reclaim the optical table” and focus on their research not the experimental set-up

Twin-track innovations in cryogenic cooling and optical table design are “creating the space” for fundamental scientific breakthroughs in quantum communications, allowing researchers to optimize the performance of secure, long-distance quantum key distribution (QKD) using engineered single-photon-emitting light sources.

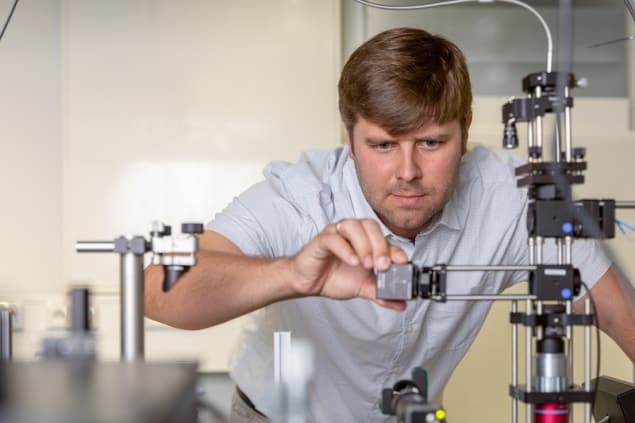

In a proof-of-concept study last year, Tobias Heindel and colleagues in the Institute of Solid State Physics at the Technische Universität (TU) Berlin, Germany, implemented a basic QKD testbed in their laboratory. The experimental set-up uses a semiconductor quantum-dot emitter to send single-photon pulses along an optical fibre to a four-port receiver that analyses the polarization state of the transmitted qubits.

The attoDRY 800 represents a game-changer for our quantum-emitter physics experiments.

Tobias Heindel, TUBerlin

Significant progress is evident along several co-ordinates, including the use of temporal filtering to minimize quantum bit-error rates and maximize the achievable secure key rate and tolerable channel losses. What’s more, evaluation of the emitter’s photon statistics during key generation demonstrates real-time security monitoring to counter any eavesdropping.

Cool optics

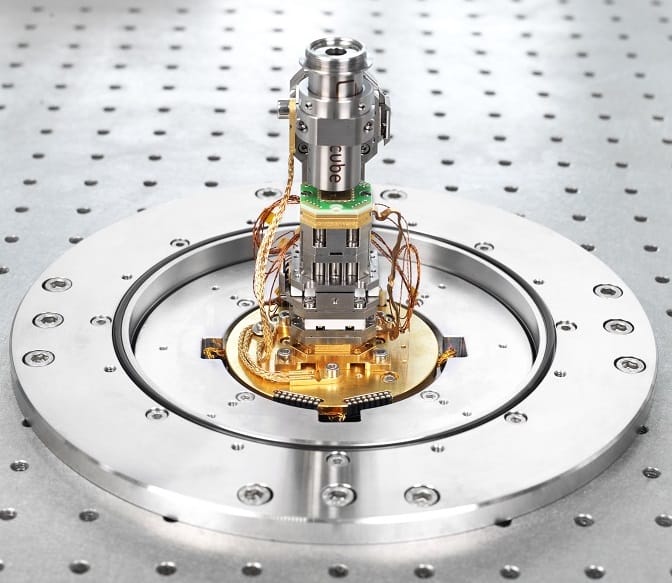

At the heart of the TU Berlin testbed is the attoDRY800 optical cryostat from attocube, a German manufacturer of specialist nanotechnology solutions for research and industry. Put simply, this closed-cycle cryostat (which requires no liquid cryogens) consists of an ultralow-vibration (ULV) cold breadboard platform that’s fully integrated into an optical table. What’s more, the cryocooler assembly is located in the otherwise unused space underneath the table – a unique design that ensures unobstructed access to the cold sample from all directions on the optical table.

“The attoDRY 800 represents a game-changer for our quantum-emitter physics experiments,” explains Heindel. “The integrated set-up means everything that usually gets in the way is now located out of sight beneath the experimental table.”

As such, Heindel and his team can freely design their experiments around the so-called “sample shroud”, an integrated vacuum enclosure surrounding the cold plate and sample (in this case, a cryogenically cooled semiconductor quantum dot measuring just a few tens of nm across).

If required, the cryostat’s automated temperature control (between 3.8 and 320 K) also supports lengthy, unattended measurement cycles in which the sample is kept cold for weeks or months at a time. “Ultimately,” Heindel adds, “the ease-of-use and flexibility of this cryostat allow us, in large part, to focus on our science and not the enabling experimental technologies.”

Efficiency gains

Being a closed-cycle cryostat, the attoDRY800 provides a convenient replacement for traditional optical helium-flow cryostat set-ups. The absence of liquid cryogens represents a win-win, ensuring reduced running costs and significant workflow efficiencies – i.e. no need for researchers to spend time replacing empty helium gas cylinders every few days. “Like a good referee in football, you very quickly stop thinking about the cryostat – it’s just an integral part of the experiment,” notes Heindel.

Those efficiency gains extend to the optical testbed, where the ULV performance of the attoDRY800 ensures long-term stable coupling of single photons from the quantum-dot emitter into a singlemode fibre. (Worth noting as well that the cryostat’s ULV capability has been evidenced separately by attocube engineers as part of an in-house study of wide-field imaging in cryomicroscopy – their results showing no detectable influence of vibrations on the image resolution between cryostat on/off down to the diffraction limit.)

Like a good referee in football, you very quickly stop thinking about the cryostat – it’s just an integral part of the experiment.

Tobias Heindel, TUBerlin

To further optimize photon collection efficiency, users can specify high-numerical-aperture apochromatic objective lenses (NA = 0.81–0.95) integrated into the cryostat, into the vacuum shroud, or located on the outside of the shroud but in close proximity to the optical windows. For the TU Berlin team, however, a high-NA objective inside the cryostat is a must-have to guarantee extremely low relative spatial and vibrational drift. “This is a big plus,” notes Heindel, “because the optics for collecting photons are at the same cryogenic temperature as the quantum-dot emitter.”

According to attocube, the long-term stability of the attoDRY800 at base temperature – measured over 40 hours as part of the same in-house study highlighted above – shows no measurable drift, while drifts as a function of temperature are up to a factor of 20 better than alternative solutions thanks to the integrated low-temperature objectives.

As for precise positioning and manipulation of the quantum-dot source, the cold breadboard space is designed to host several of attocube’s patented nanopositioners. “We have a stack of three slip-stick piezo actuators that move the sample with respect to the optical access,” explains Heindel. “That could be an optical fibre integrated within the cryostat or an objective lens located inside or outside the cryostat.”

The quantum roadmap

On the commercial front, TU Berlin is emerging as a “lighthouse customer” for the attoDRY8000, with attocube now having installed three of the cryostats (plus optical tables) in the university’s Institute of Solid State Physics. Heindel, for his part, has two more attoDRY800 systems on order which will be integrated in one large “double-table” configuration, part of an experimental testbed that will see two quantum-light sources used for QKD via a common relay station.

“The testbed will be an early-stage demonstrator of a star-like topology that, we hope, will be scalable for a future metro-area quantum network,” he explains. “We are also deploying fibres and free-space optical links to other buildings here at TU Berlin to evaluate options for a quantum local-area network architecture.”

The direction of travel is clear, with the TU Berlin team moving beyond point-to-point quantum connections to address more complex issues than the sharing of a secure key between two parties. “We are working together with Freie Universität Berlin, Humboldt Universität zu Berlin and a number of non-university research institutions in Berlin and Brandenburg to develop a Berlin-wide quantum network,” concludes Heindel.

Just last month, the same consortium was confirmed as the first so-called Einstein Research Unit of the Berlin University Alliance. This cross-disciplinary initiative brings together expertise in theoretical and experimental physics, applied mathematics, computer science and machine learning to explore aspects of “quantum digital transformation”, including near-term quantum computational devices and quantum processors. The unit will be funded with €2m annually for an initial three years.

Sponsored by attocube

Quantum innovation: part of the attocube DNA

The product portfolio at attocube covers a lot of bases – from precision motion components (such as nanopositioners and displacement-measuring interferometers) to measurement platforms (such as scanning probe microscopes), from closed-cycle cryostats for scientific applications to turnkey solutions for materials science and nanospectroscopy. Those products are also put to work across a range of operating conditions – from ambient to ultralow temperatures, from high magnetic fields to ultrahigh vacuum.

“Think one-stop shop, think vertical integration,” explains Florian Otto, head of product management at attocube. “We are facilitators of cutting-edge quantum research and that starts and ends with a granular understanding of the customer’s evolving requirements.”

As such, it’s essential for Otto and colleagues to see “first-hand what users need to maximize their scientific impact” – a key driver of attocube’s engagement with several pan-European R&D collaborations and a diverse network of research and industry partners.

A case in point is ASTERIQS. This three-year, €10 million initiative is funded by the European Union’s Quantum Flagship programme to develop next-generation diamond sensors for the measurement of a range of parameters (temperature, pressure, magnetic and electric fields) and the investigation of molecular-scale spintronic devices.

On a parallel track, attocube is also a participant in another Quantum Flagship project called SQUARE. This three-year effort, funded to the tune of €3 million, is seeking to “establish individually addressable rare-earth ions as a fundamental building block of a quantum computer, and to overcome the main roadblocks on the way towards scalable quantum hardware”.

Closer to market, meanwhile, quantum technology collaborations are under way with various industry partners, including millikelvin solutions for scanning probe microscopy (with Bluefors, Leiden Cryogenics and Oxford Instruments) and a cryogenic scanning microwave impedance microscope (with Primenano).

“Our mission at attocube is the same today as it’s always been,” says Otto. “To provide enabling technologies that will unlock the creativity, ingenuity and imagination of our users.”