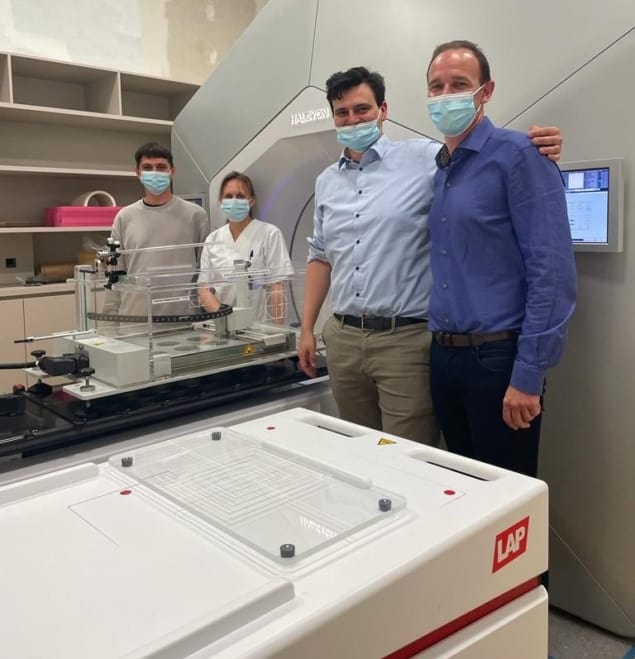

The THALES 3D SCANNER from LAP has been specifically designed for acceptance, commissioning, and quality assurance of bore-type image-guided linacs such as Varian’s popular Halcyon machine

After 30 years of outright domination in the radiotherapy suite, conventional C-arm beam-delivery systems are now being joined by bore-type machines that look more like a CT or MR scanner. Initially driven by the emergence of MR-guided radiotherapy, which can only be realized with a ring-shaped design, image-guided radiotherapy machines with the same geometry have found favour in the clinic for their speed, simplicity, and improved patient comfort. Early adopters of Varian’s Halcyon system have even reported a 70% reduction in energy usage compared to a previous installation of the vendor’s more traditional TrueBeam radiotherapy machine.

But the more confined geometry of a ring-shaped design demands a different approach to quality assurance. Take, for example, the water phantom that is used by medical physicists to record accurate dosimetry measurements when commissioning a new radiotherapy system, or for periodic checks of the radiation beam profile during the machine’s lifetime. “Medical physicists want independent QA and verification tools to confirm that the radiotherapy system is working as it should,” comments Thierry Mertens, business development manager for healthcare at LAP, a company that specializes in laser systems and radiotherapy QA. “A water phantom provides rigorous beam data and beam model visualizations to verify that the system is delivering the correct dose to the patient.”

While water phantoms originally designed for conventional linacs can be used with ring-shaped systems, Mertens says that their large size and weight adds unnecessary complications to the measurement workflow. For a start, extra care must be taken to ensure the phantom does not collide with the sides of the machine as it moves into the opening, while additional corrections need to be made to compensate for the heaviness of the water tank on the couch.

In contrast, the THALES 3D SCANNER has been designed from the outset to validate bore-style machines such as the Halcyon, as well as Varian’s new AI-enabled Ethos adaptive radiotherapy system. For the medical physicist that means greater workflow efficiency: the compact system works seamlessly with the smaller 3D volumes of these machines, with extra guidance plates to enable different types of detectors to be incorporated into the device. The motorized phantom offers an automated set-up that takes less than 15 minutes, as well as pre-defined measurement sequences to help the medical physics team complete their test routines more quickly. Dedicated software is also provided for acquiring and analysing the data, with a rolling upgrade programme to improve the functionality in response to customer feedback.

“LAP has carefully considered the design to make the device as easy to use as possible,” says Thierry Gevaert, professor at the Vrije Universiteit Brussel and deputy head of the radiotherapy department at UZ Brussel (UZB) in Belgium. “We use a water phantom a few times a year, and with this system there is no need to relearn the measurement process each time. Many of the steps are automated, so we don’t need to waste time finding the right position of the chamber before starting the measurements.”

The THALES 3D SCANNER is the second iteration of the company’s water phantom, with the first version designed specifically for commissioning and testing a new generation of MR-guided linacs such as the MRIdian MR-guided system from ViewRay. Released in 2021, the THALES 3D MR SCANNER is fully compliant with the challenging requirements of the MR-linac environment, with all system components made from non-ferromagnetic materials that have been certified for use within the MRI scanner’s 0.35 T magnetic field. “The THALES 3D MR SCANNER provides a golden-standard dose accuracy check for MR-guided radiotherapy systems,” comments Mertens. “It is a perfect fit for commissioning the beam model of the MRIdian system.”

The THALES 3D MR SCANNER has already been used by several radiotherapy centres around the world to support the commissioning and acceptance of the MRIdian system. At UZB, for example, the medical physics team were given just five weeks to complete their commissioning and acceptance protocols, as well as machine and patient-specific QA, before the machine was deployed in the radiation oncology clinic. “With only a day and a half of training, we were able to set up the phantom and take all the measurements by ourselves,” comments Gevaert. “The software is very intuitive, and we were able to collect all the necessary data within a week.”

When UZB’s satellite centre, ASZ Aalst, acquired a Halcyon machine, Gevaert was keen to see whether the THALES 3D MR SCANNER could be used to check the beam parameters that had been provided by the vendor. Because it’s not used very often, a water phantoms is a big investment for just one machine,” Gevaert points out. “We wanted to see whether we could translate our MR version of the THALES system to the Halcyon, since both machines have the same geometry.”

Both Viewray’s MRidian and Varian’s Halcyon come pre-commissioned, with all the beam data already loaded into the planning system, but Gevaert says that it is still important for medical physicists to verify that the data is correct. “We wanted to use a water phantom for the Halcyon as we believe it is the golden standard for acquiring and remeasuring beam data,” he comments.

Working with the engineers from LAP, Gevaert found that it was straightforward to set up the MR version of the phantom to work with the image-guided Halcyon. Just one new adjustment was needed to level up the device, since otherwise the weight of the water caused the phantom to sag when it was positioned on the couch. “We were one of the first to use the MR version with the Halcyon, so we needed to check that the measurements would still be accurate,” said Gevaert. “We found a good agreement with the data we received from the company.”

Meanwhile, the newly released THALES 3D SCANNER offers all the same functionality and performance as the MR-enabled device, with the only major difference being that the MR-specific capabilities have been stripped out to produce a more affordable solution for treatment centres that plan to install one or more image-guided bore-type machines. Varian has certified the phantom to be fully compatible with both its Halcyon and Ethos machines, and the device shares the same regulatory approvals in the US and Europe as the original MR-compatible version.

Both iterations of the phantom come with an annual maintenance visit, an ongoing programme of software and hardware updates, and a configurable multi-year warranty. “We know we are the new kids on the block. Our modern phantom design has been shaped by clinical physicists and we continue to incorporate their feedback to inform our upgrade programme,” says Mertens. “We will continue to improve the product through new software-enabled capabilities.”

As an example, Gevaert is currently working with LAP on new functionality that will make it possible to benchmark new dosimetry measurements against previous readings or a reference dataset. “That will enable us to directly compare measurements taken at different times,” he said. “Ideally we want to have everything built into one piece of software to avoid the need to export the data into another tool.”

Mertens and his colleagues at LAP are also evaluating the THALES water phantom for other bore-type accelerators such as Elekta’s MR-guided Unity and Accuray’s Radixact systems. “The voice of the clinical radiotherapy user is fundamental to our requirements-gathering and for understanding how the machine is being used in a clinical context,” Mertens adds.

- For further information, see the on-demand LAP webinars: Commissioning and QA workflows of MR-Linac with the THALES 3D MR SCANNER and User experience of MRIdian Linac commissioning and QA with the THALES 3D MR SCANNER.

Note that LAP and THALES are trademarks of LAP. Designations of other companies and products are only used to describe the application of our products.