A passive vacuum pump that uses 3D-printed surfaces to better absorb gas molecules has been unveiled by researchers in the UK. It removes gas nearly four-times faster than a similar system with a flat surface. The pump could make it easier to design quantum sensors that require high-vacuum conditions.

Cold atoms are at the heart of many quantum-sensing technologies. For example, atom interferometry is used to measure tiny deviations in local gravity – which can be used to map underground infrastructure.

Cold-atom systems must operate at high vacuum and most vacuum pumps are mechanical or electrical in nature. The size of these active pumps and the energy that they consume makes it difficult to operate sensors in remote or mobile scenarios – particularly on satellites. As a result, researchers who are designing quantum sensors are keen on reducing or even eliminating their reliance on active pumps.

One solution is the use of passive pumps, which have surfaces made from materials that absorb large numbers of gas molecules. Now, Lucia Hackermueller and colleagues at the University of Nottingham, Torr Scientific and Metamorphic Additive Manufacturing have created two new textured surfaces that accelerate passive pumping.

Bounce optimization

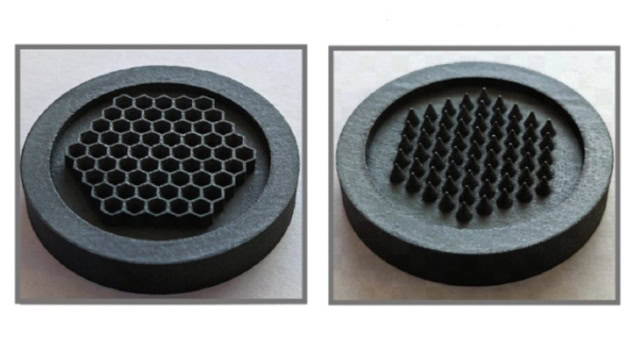

One of their surfaces is a hexagonal array of tapered pockets that resembles a honeycomb. The other surface is a hexagonal array of conical protrusions. They chose their designs after doing Monte Carlo computer simulations of how gas molecules behave near textured surfaces. When a molecule collides with a flat surface it will either be absorbed or bounce off the surface and escape. However, if the surface has 3D structures on it, a molecule may ricochet back and forth several times between structures before it escapes. Each collision increases the chance that the molecule will be absorbed by the surface. So, the researchers sought to optimize the number of bounces in their simulations.

Vacuum, the enabling technology

They then used the 3D printing of a titanium alloy to create the two promising designs on hockey-puck sized flanges that could be installed in a conventional high-vacuum system (see figure). The final step in the fabrication process was to coat the surfaces with a nonevaporable getter, which is a material designed specifically to absorb gas molecules in a vacuum system.

The team found that their hexagonal-pocket design pumped gas 3.8 times faster than a flat surface – and the hexagonal-protrusion design achieved a performance that is nearly as good.

Team member Ben Hopton at the University of Nottingham says, “What’s exciting about this work is that relatively simple surface engineering can have a surprisingly large effect. By shifting some of the burden from active pumping to passive surface-based pumping, this approach has the potential to significantly reduce, or even remove, the need for bulky pumps in some vacuum systems, allowing quantum technologies to be far more portable.”

The research is described in Physical Review Applied.