The assembly of 2D nanosheets on the surface of emulsion nanodroplets leads to the stabilization of the emulsion and requires only a tiny amount of material – report physicists in the UK. Furthermore, the team has developed a model that allows fine-tuning of the solvent composition so the droplets could be used to create components for a range of applications from strain sensors to batteries. The emulsions also raise the possibility of printing large-scale devices in a matter of minutes, which could have an important impact on electronics fabrication.

Wouldn’t it be great to print with 2D materials such as graphene? The answer is yes for many reasons, but how to do so is a puzzle that has confounded scientists working with 2D materials since Konstantin Novoselov and Andre Geim first isolated 2D sheets of carbon (graphene) in 2004. A thousand papers have been published on this subject, but the question regarding printing remains open. One important challenge is how to overcome the well-known coffee ring effect when using droplets to print thin layers of graphene or other 2D materials. This effect involves solids in a droplet forming a ring when the droplet evaporates on a surface – and results in defects when printing conductive coatings.

Now, researchers at the University of Sussex have come closer to making large-scale printing with 2D materials possible. The inspiration came when physicist Alan Dalton was mixing salad dressing and thought about adding graphene to liquid emulsions. An emulsion is a combination of two liquids that normally do not mix – like oil and water. In an emulsion, one of the liquids exists as droplets within the other liquid – like droplets of oil in a vinegar-based salad dressing.

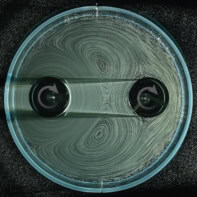

Thin nanosheets are known to stabilize emulsions by covering the surface of droplets. The result is a Pickering or armoured emulsion, which is also found in some foods.

Armoured droplets

Dalton and colleagues armoured tiny droplets in an emulsion with thin layers of graphene, forming a shell that is just a few nanometres thick. This microscopic, but functional structure requires only 0.001 vol% of graphene in solution, which is the lowest value ever reported.

Dalton comments, “In bringing the graphene coatings of the liquid droplets down to atomically-thin layers, and in opening wide the potential for real-world applications by being able to do so with any liquid material, this research development will significantly advance the emerging and scientifically exciting field of liquid electronics”.

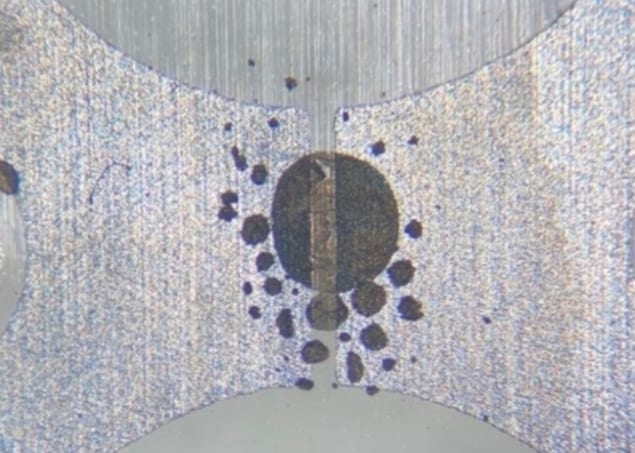

The armoured droplets offer a solution to the coffee ring problem because a continuous conductive pathway is formed upon drying. As a result, electronic devices could be printed from emulsion droplets.

Fine-tuned for different applications

Moreover, armoured droplets can be produced in any liquid, so they could be fine-tuned for different applications. Conductive droplets could be used for wrapping soft polymers such as silicone, for example, to create wearable strain sensors. Such devices have increased sensitivity at low graphene loading.

Droplets bounce off each other in new triple Leidenfrost effect

An important potential application is the development of better batteries for electric vehicles. Such batteries would be cheaper and more sustainable because they would require less graphene or other 2D nanosheets to coat the droplets used in their manufacture.

“We are also investigating emulsion assembly of battery electrode materials to enhance the robustness of these energy storage devices,” says Sussex’s Sean Ogilvie, who is lead author of a paper in ACS Nano describing the research.