A series of nanoscale mechanisms that make a transparent oyster shell resistant to the piercing teeth of predators has been revealed by researchers in the US. The discovery could lead to better transparent protective equipment, such as face guards and bullet-resistant windscreens that stay intact and retain visibility, even after multiple impacts, the researchers say.

The discoveries were made by Christine Ortiz and Ling Li at the Massachusetts Institute of Technology. The pair focused on the shell of the windowpane oyster, Placuna placenta, which lives in waters off the Philippines and other parts of the tropical central Indo-Pacific region. As the only transparent bivalve shell, it might be the toughest see-through material in nature.

Smashed and stabbed

Ortiz first encountered the oyster when she became interested in a US Department of Defense initiative to replace its laminated-glass bullet-resistant windscreens with a material that can retain visibility after multiple hits. During a trip to the Smithsonian Institution in Washington, DC, she and her colleagues counted about 10 animal species with semi-transparent armour. Since bivalve shells are especially tough, the group settled on the calcite-based shell of P. placenta. “We smashed it, and it wouldn’t break,” she says, adding “We stabbed the shell with a knife, and it still wouldn’t break.” This is unlike a sample of the mineral calcite, which “broke into a million pieces”.

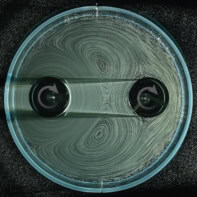

Using a variety of electron-microscopy techniques, Ortiz and Li found that unlike in most materials, cracks did not radiate from points of impact on the shell. The studies revealed that the shell’s toughness is a result of how very thin calcite layers respond to being hit. These layers make up about 99% of the mass of the shell and have an average thickness of 300 nm – about 1/300 the thickness of a human hair. The layers comprise elongated, diamond-shaped tiles that are arranged like a mosaic. Between the calcite layers lie much thinner layers of organic material.

Twinning bands

Attempts to break through the shell using a hammer with a micron-sized diamond tip caused narrow bands of atoms within individual calcite crystals to shift into new orientations, a phenomenon known as deformation twinning. The crystal structure in each band behaves like a loosely bolted builder’s scaffold that leans to one side before impact, and then leans the opposite way once struck. The new orientation looks like a mirror image, or twin, of the original crystal structure. Each twinning band was only about 50 nm wide and stops at the top and bottom of the layer. These bands absorbed much of the energy of impact without the crystal cracking.

The team also discovered that twinning triggered other inelastic mechanisms that helped dissipate energy. These include the formation of tiny cracks between and within calcite layers and the stretching of the organic material between calcite layers.

While twinning was also observed in similar experiments on single-crystal mineral calcite, the twinning bands were much wider and propagated throughout the sample. This resulted in cracks that weakened the structure and reduced transparency by scattering light.

Ballistic materials

Although the oyster shell is far from bulletproof, Ortiz suggests that its energy-dissipation mechanisms could be used to develop materials suitable for equipment that could protect soldiers’ eyes and faces, bullet-proof shields, and other protective equipment for combat use. “Our plan is to swap out these organic materials with ballistic materials,” she says. “We have a lot more ceramics that we can use.”

Markus Buehler, also of MIT but not involved in the research, told physicsworld.com “I am quite excited about these findings and think they have the potential to open a new paradigm in armour design.” “The question of how primarily brittle calcites can be transformed into structurally sound and tough materials is a long-standing question, and this work reports an important step towards that goal.” However, “It may be difficult to manufacture synthetic materials of the same hierarchical structure and complexity,” he cautions.

Peter Fratzl of the Max Planck Institute of Colloids and Interfaces in Potsdam, Germany, points out that while practical materials will probably not be made of calcite, the research offers a “blueprint for the multi-scale design of materials, which could be based on engineering ceramics other than calcite, which have genuinely better properties for armours, for example”.

The research is described in Nature Materials.