Making a sandcastle is child’s play because adding a seemingly random amount of water to dry sand makes a sticky material that is easy to work with. However, exactly why sand is sticky over a wide range of water content had been a mystery, with important implications in civil engineering and especially the prevention of landslides. Now, an international team of researchers thinks that it has the answer, based on a microscopic study of exactly how water glues sand grains together.

This glue is thought to be the familiar capillary force that causes water to move up the edge of a container. However, the structures that are formed when the grains stick together are extremely complex and vary greatly with how much water is in the sand. This has made it very difficult to understand exactly how the mechanical properties of sand are affected by water.

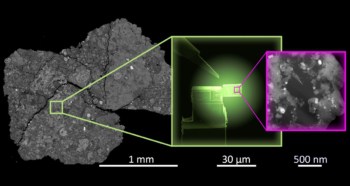

Now, Stephan Herminghaus of the Max Planck Institute for Dynamics and Self Organization in Göttingen, Germany, and colleagues have tackled this problem by studying 3D images of wet glass beads using X-ray microtomography (Nature Materials 7 189). The beads were of a similar shape and size as natural sand.

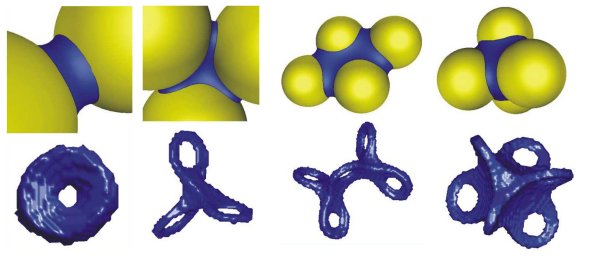

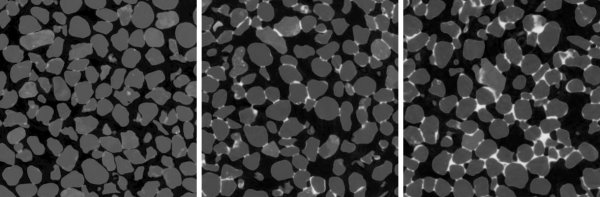

When a liquid was added to the dry beads, liquid structures called “capillary bridges” were seen to form between grains. As more liquid was added to the beads, small bridges grew into larger structures. As these bridges grew, the surfaces of individual beads came into contact with more water, which tends to increase the binding effect of the water. However, the size of the capillary forces decreases as the bridge structures get bigger and the team believe that these two effects cancel each other out, so that the forces binding the beads together remain the same as the moisture content changes.

As the water content is further increased, the bridges between beads coalesce and act to bind several beads together into larger structures. These structures grew as more water was added but their mechanical properties — including stickiness — remained the essentially the same.

This was confirmed by the team by measuring how the material responded to an applied stress.

“Our work gives a clear and detailed physical understanding of how a wetting liquid is distributed within a granular pile and how it influences its mechanical stability by virtue of capillary forces,” team member Ralf Seemann told physicsworld.com. “The result explains why the mechanical properties are unaffected by the amount of liquid in the sample and is valid for non-spherical grains, like sand, as well as spherical ones.”

The imaging technique could lead to a better understanding how grain–liquid–air interfaces interact in granular materials. Such knowledge could be used to prevent powders from forming clumps or even understanding and preventing landslides.

The team, which includes scientists from the ESRF in Grenoble, France, and the Australian National University, will now explore the limits of the behaviour they have observed by looking more closely at the packing geometry, packing density and wetting angles of the water–sand structures. It will also perform time-resolved studies of what happens a sheering force breaks these structures and the liquid is redistributed, which could shed light on the dynamics of how wet sand flows.