Researchers in the US and China have made the first silk hard drive using a technique called tip-enhanced near-field infrared nanolithography (TNINL). The device, which can store digital data with a density of 64 GB per square inch, is robust in the face of harsh conditions such as heat, moisture, gamma radiation or high magnetic fields. While a silk-based hard drive is unlikely to match the speed and storage capacity of state-of-the-art solid-state drives at the same cost, its unique set of features makes it promising for electronics that could be implanted in the body.

Lithography techniques are routinely used to make devices with optical storage densities as high as several hundred GB per square inch. However, it can be time-consuming to create small features with these methods, and it also requires costly and sophisticated fabrication procedures. Another drawback is that diffraction limits the resolution of conventional optical lithography to around half the wavelength of the illuminating light – roughly hundreds of nanometres for visible light. This makes further increases in storage density (beyond current industry standards) difficult to achieve.

Overcoming the diffraction limit with near-field light

An alternative technique known as scattering-type scanning near-field optical microscopy (s-SNOM) offers a possible solution. This technique gets around the diffraction limit because it depends on near-field light – that is, the component of light that “wraps around” surfaces – instead of the diffraction-prone far-field light (which propagates away from the structures that scatter it). Near-field light is already commonly used in nanoscience as a tool to fabricate, manipulate and characterize photosensitive structures. For example, researchers use so-called “evanescent” light fields for nanolithography of polymeric materials, and for processing nanoscale features in material surfaces when making optical nanodevices.

Researchers led by Tiger Tao of the Chinese Academy of Sciences in Shanghai, Mengkun Liu of Stony Brook University in New York and Wei Li of the University of Texas at Austin have now used a variation of s-SNOM to write and read information on a layer of silk protein.

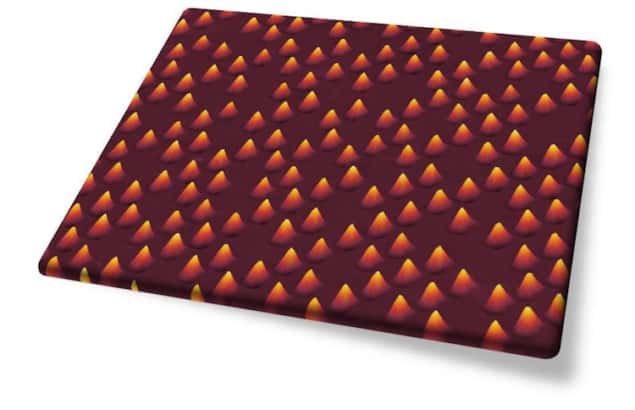

To make their silk drives, the researchers took silk extracted from silkworm cocoons and spin-coated a thin film of it (in the form of an aqueous solution) onto either a gold or a silicon substrate. They then created nanoscopic patterns in this film using an s-SNOM equipped with a mid-infrared laser light source. The frequency of the laser could be tuned between 1495 and 1790 cm–1, which covers the wavelengths at which silk proteins absorb light. By focusing the laser onto the sharp tip of an atomic force microscope placed near the silk surface, they were able to induce topological and/or phase changes in the silk film at roughly 30-nm length scales.

Information can be repeatedly written and erased

With these induced changes spaced 100 nm apart, the team achieved a data storage capacity equivalent to around 64 GB per square inch, Liu says. While the patterns thus created are robust to harsh conditions, the method nevertheless allows information to be repeatedly written onto and erased from the film.

Silk-based sensor analyses sweat biomarkers in real time

The advantages of the technique are many, Liu tells Physics World. Thin silk films are easy to spin-coat onto various substrates, including curved and soft materials. Such films also offer two entirely different ways to read out the encoded data. The first option is to use straightforward AFM “mapping” in which topographic protrusions are recognized as “1s” while flat topographical features correspond to “0s”. The second, more innovative way is to use a laser readout technique that differs from conventional optical methods in that the spectroscopic information thus obtained is multi-coloured. What is more, by varying the laser’s writing power, the researchers demonstrated that they could achieve so-called “higher-dimensional” or greyscale data storage, where individual data points take on values other than a binary zero or one.

Finally, Liu notes that silk is an organic material that mixes and interfaces well with many biological systems, including biomarkers in blood. The information in these biomarkers could therefore be encoded and stably stored in a silk-based hard drive. Indeed, members of the team, who report their work in Nature Nanotechnology, now plan to integrate their silk drive with biological materials for bio-information storage applications. “We will be investigating body implantation in the near future as well,” Liu says.